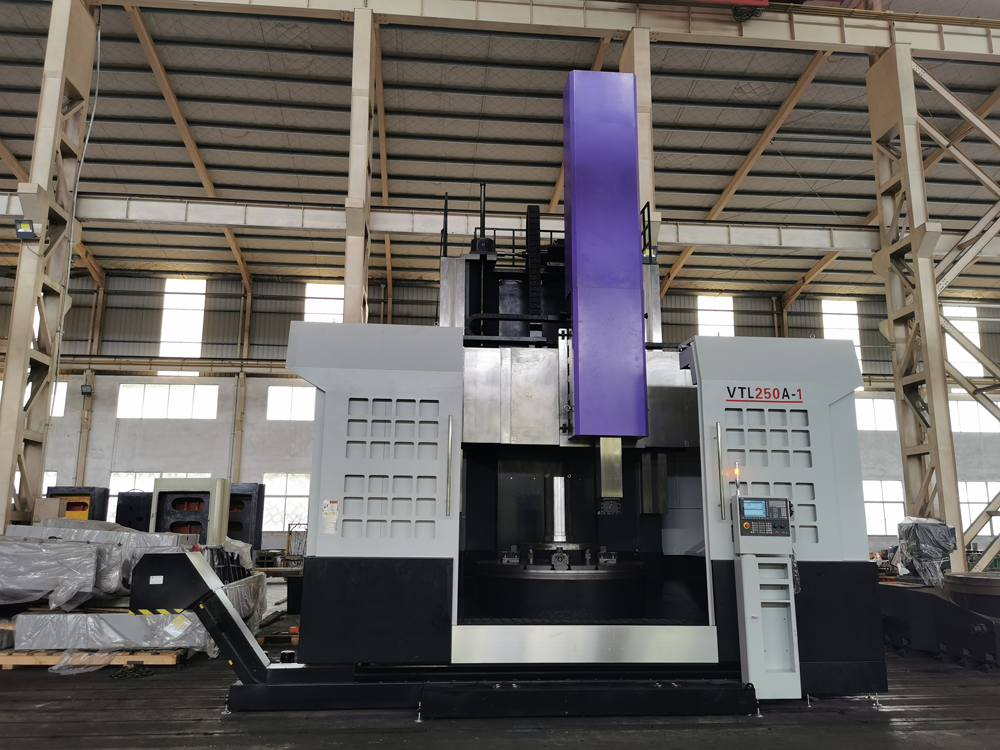

Nnukwu-ọnụ ọgụgụCNC vetikal lathesbụ nnukwu ígwè ọrụ, nke a na-eji hazie nnukwu na arọ workpieces na nnukwu radial akụkụ na dịtụ obere axial akụkụ, na mgbagwoju shapes. Dị ka ihe atụ, cylindrical elu, ọgwụgwụ elu, conical elu, cylindrical oghere, conical oghere nke dị iche iche discs, wiil na setịpụ nke workpieces nwekwara ike hazie site n'enyemaka nke ndị ọzọ ngwaọrụ maka threading, okirikiri elu, profiling, egwe ọka na egweri.

Oge inyeaka nke nnukwu-ọnụ ọgụgụIgwe CNC VTLdị mkpụmkpụ. Ọ nwere ike mezue niile nhazi ọdịnaya n'otu clamping. Gbalịa na-ahọrọ na-emeghe fixture na elu rigidity, nke na-apụghị igbochi na ngwá ọrụ ụzọ, na ike mezue nhazi nke workpiece n'ime nso nke spindle ọrịa strok. Dị ka ngwá ọrụ igwe akpaaka nke ukwuu, mkpu dị iche iche ga-apụta mgbe oge ejiri ya. Ụfọdụ bụ ọdịda sistemu, ụfọdụ bụ ntọala paramita na-ezighi ezi, ụfọdụ bụ ọdịda arụrụ arụ. Mkpu ndị fan bụ otu n'ime ha.

Mgbe ọnọdụ dị otú ahụ mere, buru ụzọ lelee onye na-akwado ime. Ọ bụrụ na ọ tụgharịghị, wepụ ya iche wee hụ. Ọ bụrụ na ọ ruru unyi nke ukwuu, jiri mmanya ma ọ bụ mmanụ ụgbọala hichaa ya tupu ịwụnye ya. Ọ bụrụ na enwere mkpu, ị ga-eji dochie servo amplifier. HC pụtara. Oti mkpu ugbu a, tumadi iji chọpụta ihe na-adịghị mma ugbu a n'akụkụ DC, buru ụzọ lelee servo parameters, wee wepụ eriri ike moto. N'ime oge ahụ, enwere mkpu iji dochie servo amplifier. Enweghị mkpu. Gbanwee moto na ahịrị ike na axis ọzọ iji chọpụta ma ọ bụ moto ma ọ bụ eriri ọkụ. Nsogbu: Ọ bụrụ na J pụtara na ngosi, ọ dabere ma ọ bụ nsogbu PC. Lelee ma motherboard, interface ntụgharị osisi na ngwaọrụ njikwa PCRAM ziri ezi, dochie na debug ruo mgbe ekpebie ihe kpatara ya, wee dozie nsogbu ahụ.

Mgbe ọnọdụ dị otú ahụ mere, buru ụzọ lelee onye na-akwado ime. Ọ bụrụ na ọ tụgharịghị, wepụ ya iche wee hụ. Ọ bụrụ na ọ ruru unyi nke ukwuu, jiri mmanya ma ọ bụ mmanụ ụgbọala hichaa ya tupu ịwụnye ya. Ọ bụrụ na enwere mkpu, ị ga-eji dochie servo amplifier. HC pụtara. Oti mkpu ugbu a, tumadi iji chọpụta ihe na-adịghị mma ugbu a n'akụkụ DC, buru ụzọ lelee servo parameters, wee wepụ eriri ike moto. N'ime oge ahụ, enwere mkpu iji dochie servo amplifier. Enweghị mkpu. Gbanwee moto na ahịrị ike na axis ọzọ iji chọpụta ma ọ bụ moto ma ọ bụ eriri ọkụ. Nsogbu: Ọ bụrụ na J pụtara na ngosi, ọ dabere ma ọ bụ nsogbu PC. Lelee ma motherboard, interface ntụgharị osisi na ngwaọrụ njikwa PCRAM ziri ezi, dochie na debug ruo mgbe ekpebie ihe kpatara ya, wee dozie nsogbu ahụ.

Kedu ihe ndị chọrọ nlebara anya na nlekọta nke nnukwu CNCỌnụahịa kasị elu nke VTL?

1. Mgbe ịmalitere isi moto oge ọ bụla, enweghị ike ịmalite spindle ozugbo. Naanị mgbe mgbapụta mmanụ na-arụ ọrụ nke ọma na windo mmanụ na-abịa na mmanụ, enwere ike ịmalite spindle iji mee ka ngwá ọrụ igwe rụọ ọrụ.

2. Enwere ike iji kposara naanị mgbe ị na-atụgharị eri iji hụ na ọ bụ eziokwu na ndụ ya.

3. Na-edebe n'ime na n'èzí nkengwa igweka ọ dị ọcha, akụkụ igwe zuru oke, mkpanaka na-egbuke egbuke na mkpanaka na-egbuke egbuke na-enweghị mmanụ, na ebe ndị na-eduzi ụgbọ okporo ígwè dị ọcha ma dị mma.

4. Na-arụ ọrụ lubrication nke ebe ọ bụla mmanye dị ka ihe ndị a chọrọ (lee akara akara nke usoro mmanụ ọkụ maka nkọwa).

5. Na-elele mgbe niile na mezie tightness nke V-belt nkeCNC vetikal lathe.

6. Lezienụ anya iji lelee ọnọdụ ọrụ nke mgbapụta mmanụ iji hụ na igbe isi na igbe nri nwere mmanụ mmanụ zuru oke. Mmanụ mmanụ na tank ọ bụla agaghị adị ala karịa etiti ọkọlọtọ mmanụ ọ bụla, ma ọ bụghị ya, ngwaọrụ igwe ga-emebi n'ihi mmanye na-adịghị mma.

7. Na-asachapụ ihe nzacha ọla kọpa nke mmanụ n'ime oghere mmanụ nke igbe dị n'akụkụ akwa kwa izu iji hụ na mmanụ na-ete mmanụ dị ọcha.

8. Mgbe spindle na-atụgharị na oke ọsọ, n'ọnọdụ ọ bụla, ị ghaghị ịdọrọ aka na-agbanwe agbanwe.

Oge nzipu: Nov-24-2021