A na-akpọkwa eriri eriri ọkpọkọmmanụ ala lathe,thread ịtụgharị n'ozuzu na-ezo aka na usoro nke machining eri na workpiece na a akpụ ngwá ọrụ, tumadi gụnyere ntụgharị, egwe ọka, ọpịpị, threading egweri, egweri, na oké ifufe igbubi. Mgbe ị na-atụgharị, egwe ọka na egweri eri, nnyefe yinye nke igwe ngwá ọrụ ana achi achi na mbịne ngwá ọrụ, egwe ọka cutter ma ọ bụ egweri wheel na-akpali n'ụzọ ziri ezi na evenly tinyere axis nke workpiece site otu ụzọ maka mgbanwe ọ bụla nke workpiece. Mgbe ọpịpị ma ọ bụ threading, ngwá ọrụ (tap ma ọ bụ anwụ) na-atụgharị ikwu na workpiece, na nke mbụ kpụrụ eri uzo na-eduzi ngwá ọrụ (ma ọ bụ workpiece) ịkwaga axially.

Na ihe anyị na-tumadi aiming na bụ thread turning ijieriri eriri ọkpọkọ. Enwere ike iji ihe na-emepụta eri ma ọ bụ ihe eji eme ihe iji gbanye eriri na eriri ọkpọkọ. Agbanye eri na a na-akpụ mbịne ngwá ọrụ, hesitant ngwá ọrụ Ọdịdị dị mfe, ọ bụ a nkịtị usoro maka obere ogbe mmepụta na nhazi nke threaded workpieces. Agbanye eri na a eri comb ngwá ọrụ nwere elu mmepụta arụmọrụ, ma ngwá ọrụ Ọdịdị bụ mgbagwoju, na ọ bụ naanị adabara mbịne ezi-eze mkpụmkpụ threaded workpieces na ọkara na nnukwu-ọnụ ọgụgụ mmepụta.

Izi ezi nke lathes nkịtị maka ịtụgharị eriri trapezoidal nwere ike iru naanị 8-9, mana nrụpụta nrụpụta na izi ezi nke ndị ọkachamara.CNC ọkpọkọ threading igwea ga-emeziwanye nke ọma.

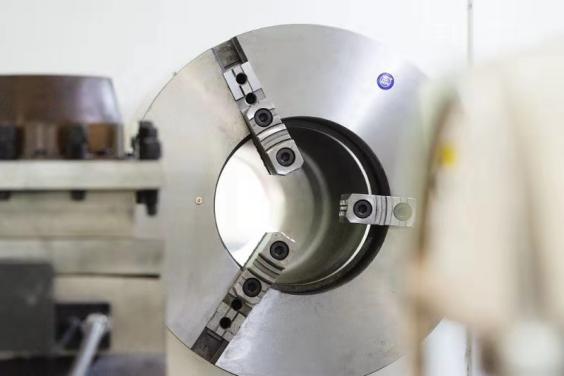

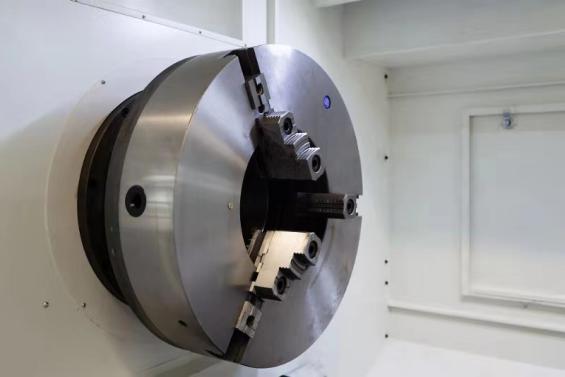

Ọkụ eriri eriri ọkpọkọigwebụ lathe kehoraizin emebere nke ọma maka ịtụgharị akwa ọkpọkọ nwere dayameta. A na-eji ya na dayameta nke oghere dịtụ ukwuu nke spindle (n'ozuzu karịa 135mm) na nchichi n'ihu na azụ nke igbe spindle. , Iji mee ka njigide na nhazi nke nnukwu ọkpọkọ ma ọ bụ mkpanaka.

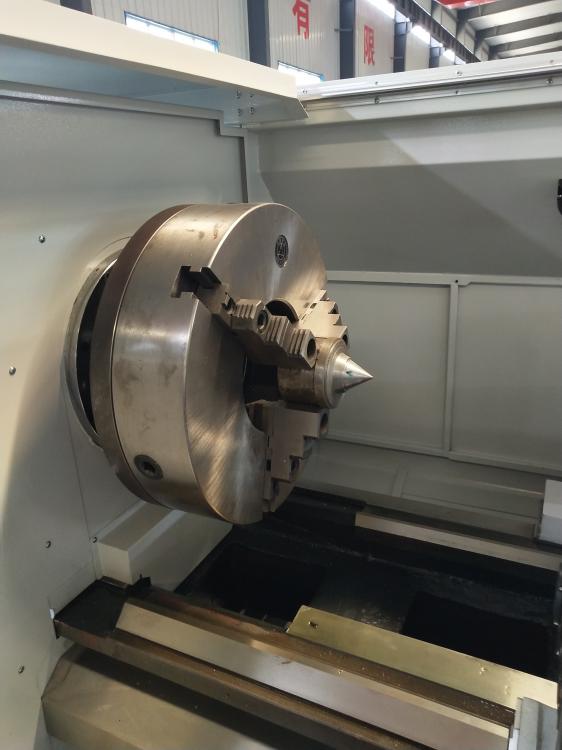

Obodo mmanụlatheigwen'ozuzu nwere a nnukwu site-na-oghere na spindle igbe, na workpiece na-clamped site abụọ chucks na ma nsọtụ nke spindle na bugharia mgbe gafere site-oghere. E nwere n'ozuzu ụzọ abụọ na-eri nri ngwá ọrụ: otu bụ otu ihe ahụ dị ka ndị nkịtị lathe site ndu ịghasa na-akwọ ụgbọala slide na ngwá ọrụ njide n'ihu nke bed; nke ọzọ bụ ewepụghị mbo na slide dị n'etiti akwa. The mpụga eri ọnwụ isi nke mma (lee akpaka oghere na mmechi eri ọnwụ isi) bee n'ime workpiece na-akpali n'ihu. Ụfọdụ ngwaọrụ maka nhazi ọkpọkọ ogologo nwekwara ngwaọrụ nkwado workpiece, dị ka etiti etiti, ihe ezumike ngwá ọrụ, na ihe nkwado azụ.

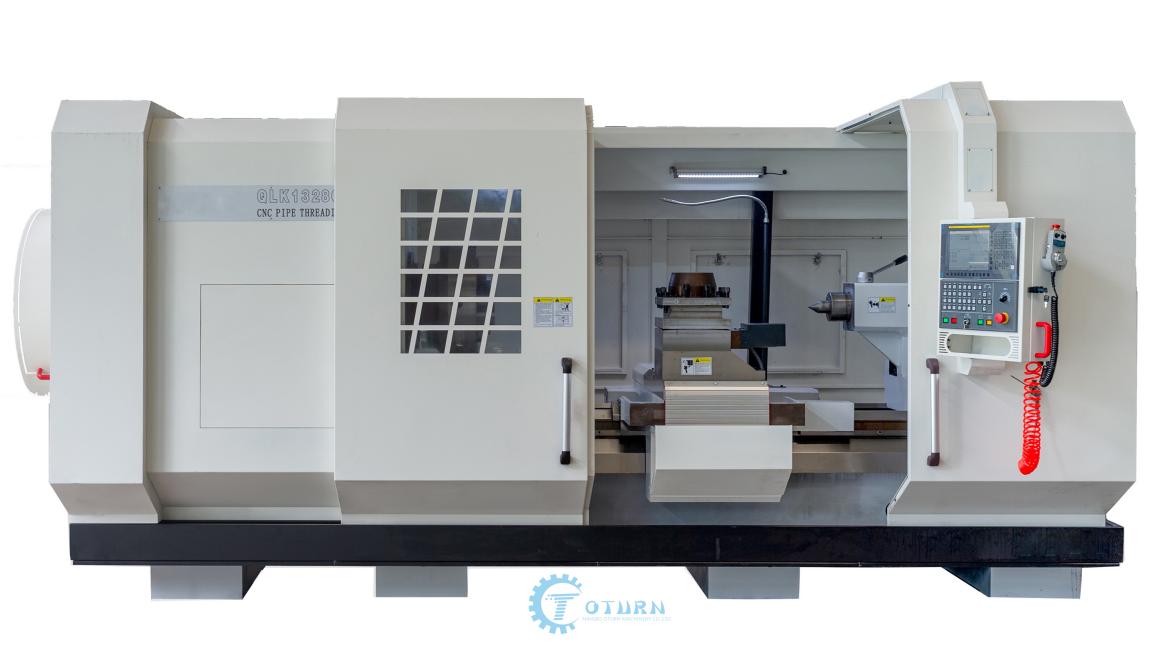

CNC ọkpọkọ threading lathekwadoro

QLK1315 / QLK1320 / QLK1323 / QLK1325 / QLK1328 / QLK1336 / QLK1345 / QKL1353 / QLK1363

QLK1320

Atụmatụ nkeelu àgwàọkpọkọ eriri eriri:

1. Ihe ndina ahụ nwere ihe nrụpụta mgbidi mbụ nke okpukpu atọ, na mgbidi azụ na-ahazi ya na ụgbọ elu nwere ogo 12, nke na-eme ka ihe siri ike nke ngwá ọrụ igwe dịkwuo mma.

2. Isi ihe na-ebufe ihe na-ebufe ọkwa bụ ọkwa, nke na-ebelata ike ike na mkpọtụ nke ngwá ọrụ igwe.

3. Iji igbe hydraulic dị iche iche, mmanye etiti, na ịdị jụụ dị ike ọ bụghị naanị na-ebelata okpomọkụ nke spindle kamakwa ọ na-edobe ịdị ọcha na mmanu nke igbe spindle nke ọma.

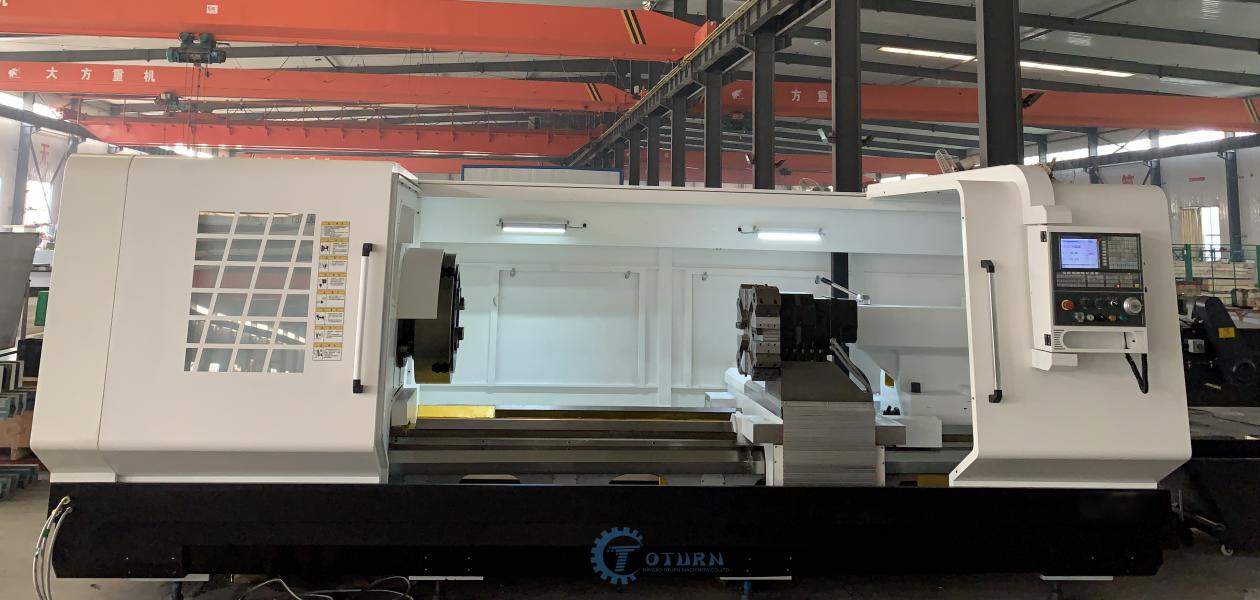

QLK1336

QLK1336CNC Mmanụ obodo lathebụ eriri eriri CNC ọkpọkọ emebere ọhụrụ. Emebere draịva isi ka ọ dabara n'ogo oge arụ ọrụ nke igwe spindle servo ahọpụtara. Full stepless ọsọ iwu, obosara ọsọ iwu nso, nke ọ bụghị nanị na-ezute chọrọ nke elu-ọsọ eri finishing, ma nwere elu ọnwụ arụmọrụ na ala mkpọtụ.

Uru na uru nke ọkpọkọ threading lathes

(1) Igwe igwe

The obosara nke ahu okporo ígwè bụ 650mm, ihe bụ HT300.Ultrasonic ugboro quenching na-enweta na HRC52.The roughness bụ Ra0.63 mgbe egweri site elu-nkenke egweri igwe.It nwere elu-nkenke na abrasion arụmọrụ. Ahụ igwe bụ ihe dị mkpa, nke na-eme ka ihe siri ike nke ngwá ọrụ dị mma dịkwuo mma.

(2)CNC Mmanụ obodo machinesIgbe isi

Integral gia igbe ụdị spindle unit, elu ike spindle servo moto,

Abụọ-ọsọ nnyefe, stepless ọsọ ụkpụrụ.

Ogologo usoro nhazi ọsọ ọsọ, ọ bụghị nanị iji mezuo ihe ndị a chọrọ nke imecha eriri dị elu, kamakwa iji nweta ihe ọkụkụ dị mma.Quenched na nkenke na-egweri gia, elu àgwà bearings, iji hụ na igwe obere mkpọtụ, ezigbo ụda dị mma.

Igbe spindle ahụ na-eji mmanu mmanu dị mma na-eme ka ọ dị mma,

ọ bụghị nanị na-ebelata okpomọkụ nke spindle, kamakwa ọ na-edobe ịdị ọcha na mmanu nke igbe spindle.

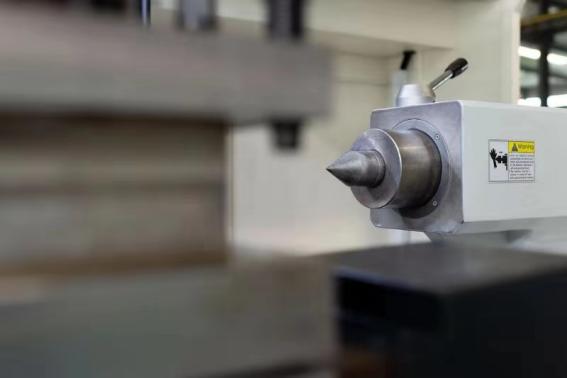

(3)Akụkụ azụ

Ngwá ọrụ igwe a bụ ọkọlọtọ nwere φ120 tailstock spindle. Mohs 6 # n'elu.

(4) Ihe oriri abụọ-axis

Ma X axis na Z axis na-anakwere draịvụ bọọlụ ziri ezi nke ọma yana ụzọ ịghasa prestress erughị ala. A na-eji screw screw bearings nkenke maka idobe na ịkwado; ihe nkedo Z shaft screw nut bụ ihe eji arụ ọrụ nkedo.

(5) CNC Turret

Ndị na-anabata (HAK21280) ihe njide ngwaọrụ kwụ ọtọ CNC. Ọ nwere njirimara nke ịdị elu dị elu, ntụgharị dị nro, ọrụ dị mfe na ihe ndị ọzọ.

Ihe anọ mere ị ga-eji họrọCNC ọkpọkọ erimachine ma ọ bụmmanụ ala machining lathe

1. Nkeeriri eriri lathenwere njiri mara ọkwa dị elu nke akpaaka, arụmọrụ dị elu na nkenke dị elu, oke ngwa ngwa, yana ọrụ dị mfe.

2.The bedside igbe na-chụpụrụ site a ugboro mgbanwe moto, na a stepless ọsọ mgbanwe. Spindle bearings sitere n'aka ndị na-emepụta ụlọ a ma ama, jaw atọ sitere na ụdị ụlọ a ma ama.

3.The modular design of the number control system dị mfe debug na mfe ịnọgide na-enwe. Axes x na z na-enweta ike dị elu, moto servo, arụmọrụ dị elu, yana ntụkwasị obi siri ike.

4.It adopts nkedo akwa saddle, slide plate, ezi uche dị n'ime ọgịrịga okirikiri nhọrọ ukwuu, elu nkenke bọọlụ ịghasa, elu nkenke, na ezi nnyefe.

Foto ndị dị na akụkụ

Nhazi ọkọlọtọ

Igwe ọkụ eletrik nke anọ ọdụ post, akpaka centralized lubrication, jụrụ oyi usoro, ọkara mkpuchi mkpuchi.

A na-eji ngwaahịa a eme ihe n'ọtụtụ ebe n'ịrụ ọrụ nhazi igwe, mmanụ ala, kemịkalụ, coal, nyocha nke ala, mmiri na mmiri nke obodo mepere emepe, na ụlọ ọrụ ndị ọzọ.

Isi akụkụ ndị fọdụrụ gụnyereọkpọkọ ọkpọkọ na njikọ.

Ụlọ ọrụ mmanụ ala bụ ngalaba mmepụta ihe nke na-ewepụta mmanụ ala (gụnyere mmanụ ala, mmanụ shale na gas) ma nụchaa ma hazie ya. Ihe mejupụtara ya bụ nchọpụta ala ala mmanụ, mmepe mmanụ na ịchọgharị mmanụ, ụgbọ njem, nnụcha na ngalaba nhazi.

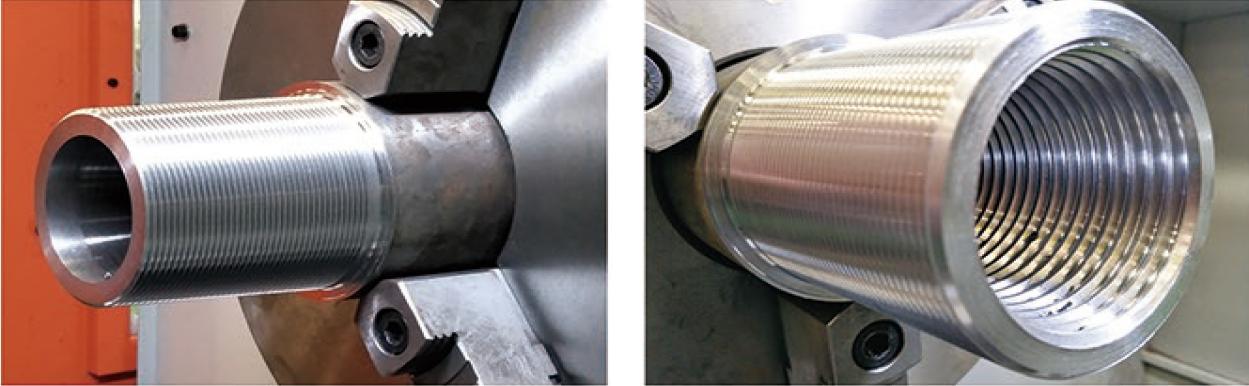

Okwu a na-ejikarị maka tubing na ụlọ ọrụ mmanụ na gas bụ Petroleum Tubing (OCTG). Ebumnuche nke ọkpọkọ mmanụ ala nwere ike ịdị iche: enwere ike iji ha wepụ ma ọ bụ ịgbanye gas, mmanụ, mmiri, uzuoku, wdg, ma nwee ike kewaa ya na casings ma ọ bụ tubing dịka ngwa ngwa. A na-eji casing dị ka oyi akwa nchekwa iji nyere olulu mmanụ aka iguzogide mmetọ nke ime ma ọ bụ n'èzí iji nọgide na-adịte aka; a na-eji tubing amịnye ma ọ bụ wepụ mmanụ.

eriri ọkpọkọing igwe ngwaọrụ a na-eji emepụta ọkpọkọ mmanụ, nke a na-ejikarị eme ihe na ụlọ ọrụ mmanụ ụgbọala. Ọ bụ ọkpọkọ ígwè eji ebu mmanụ na gas dị n'olulu mmanụ. A na-etinye ya na casing, na mmanụ na gas na-esi na ọkpọkọ mmanụ gaa n'isi mmiri.

E nwere nha abụọ nke eriri tubing, otu bụ eriri eriri taper nke nwere ụdị V nke nwere dome okirikiri nwere ezé 8 kwa inch, nke ọzọ bụ eriri ọkpọkọ ọkpọkọ V nke nwere dome gburugburu ala na ezé iri kwa inch.

Eriri bụ protrusion na-aga n'ihu nke nwere profaịlụ nha nha edobere n'akụkụ eriri gburugburu n'elu cylinder ma ọ bụ cone. Enwere ọtụtụ ụzọ maka eriri igwe, a na-ejikarị threading eme ihe na igwe n'ozuzu. Mgbe oleeriri igweon a kehoraizin lathe, mmegharị mmekọrịta n'etiti workpiece na ngwá ọrụ ga-hụ na. N'ezieeri na-atụgharị, n'ihi ihe dị iche iche, ije n'etiti spindle na ngwá ọrụ nwere nsogbu na a ụfọdụ njikọ, na-eme ka ọdịda n'oge eri na-atụgharị na-emetụta nkịtị mmepụta. N'oge a, a ga-edozi ya n'oge.

Otu esi edozi nsogbu nke nnukwu roughness, ndị a bụ aro nke ụfọdụ ndị na-arụ ọrụ ọkpọkọ nwere ahụmahụ:

1. Mgbe ị na-eji ngwá ọrụ na-atụgharị ígwè dị elu na-atụgharị, a ga-ebelata ọsọ ọsọ na-atụgharị na mmanụ na-atụgharị.

2. Mụbaa mpaghara mpaghara mpaghara nke arbor ma belata ogologo mgbatị ahụ (n'ihi na arbor adịghị esi ike nke ọma, ọ na-enwekarị ịma jijiji n'oge ịcha)

3. Belata longitudinal n'ihu akụkụ nke mbịne ngwá ọrụ na mezie nwechapụ nke ịghasa nut nke etiti slide efere (na longitudinal n'ihu angle nke mbịne ngwá ọrụ dị oke ibu, na mkpochapụ nke etiti slide ịghasa nut dị oke ibu; nke ga-eme ka ngwa ahụ dị mfe)

4. Mgbe elu-ọsọ eri mbịne, ntụgharị ọkpụrụkpụ nke ikpeazụ ịkpụ bụ n'ozuzu karịa 0.1mm, na ibe na-ẹkesiode perpendicular ka axis direction (mgbe.eriri na-agba ọsọ ọsọ, Ntugharị ntụgharị dị ntakịrị ma ọ bụ a na-ahapụ ibe ya na ntụziaka oblique, ọ dị mfe ịdọrọ eriri eriri).

5. Ekwesịrị iji mmanụ na-atụgharị elu-ọgwụgwụ ma ọ bụ mmanụ na-atụgharị mmanụ nwere oke nrụgidehazie erinke workpiece site na lathe. Iji mmanụ nhazi ígwè pụrụ iche nwere ike ime ka nsogbu nke adịghị mma na arụmọrụ dị ala.

Oge nzipu: Sep-21-2021