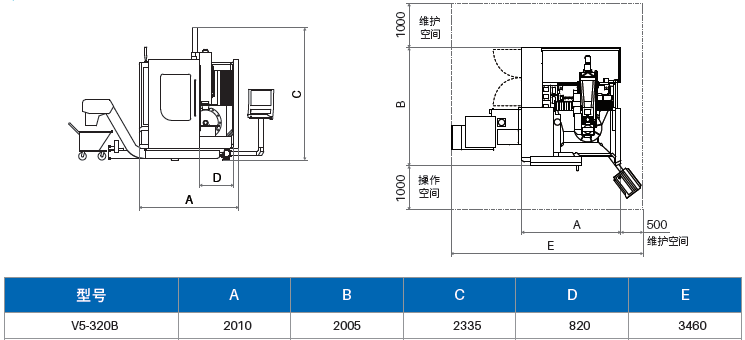

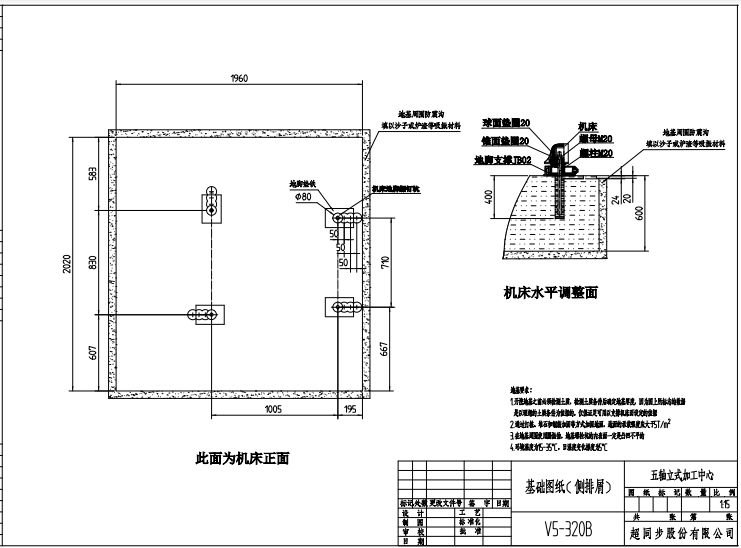

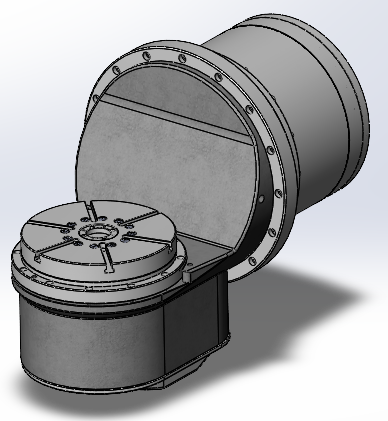

5-Axis Vertical Machining Center V5-320B

1. Nhazi n'ozuzu nke ngwá ọrụ igwe

V5-320B ise-axis machining center nakweere ihe owuwu C nke kwụsiri ike, a na-edozi kọlụm n'elu akwa, efere slide na-aga n'ihu n'akụkụ kọlụm (ntụgharị X), oche slide ahụ na-aga ogologo oge n'akụkụ efere slide (Y direction). ), na headstock na-aga n'ihu kwụ ọtọ n'akụkụ oche mmịfe (Z direction). Tebụl na-arụ ọrụ na-anakwere ihe eji arụ ọrụ otu ogwe aka arụpụtara onwe ya, yana ihe ngosi arụmọrụ ya dị iche iche eruola ọkwa dị elu nke mba ụwa.

2. Usoro nri

X, Y, Z-axis linear rails na skru bọọlụ, obere esemokwu na-agbanwe agbanwe na static, mmetụta dị elu, obere ịma jijiji na-agba ọsọ, enweghị mgbagha na obere ọsọ, nhazi ọkwa dị elu, yana ọmarịcha arụmọrụ servo.

X, Y, Z-axis servo Motors na-ejikọta ya na skru bọọlụ dị elu site na njikọta, na-ebelata njikọ dị n'etiti, na-achọpụta nnyefe na-enweghị oghere, nri na-agbanwe agbanwe, nhazi ziri ezi, na oke nnyefe dị elu.

Moto Z-axis servo nwere ọrụ breeki. N'ọnọdụ nke ọdịda ike, breeki nwere ike ijide ogwe aka moto ahụ nke ọma ka ọ ghara ịtụgharị, nke na-arụ ọrụ nchekwa nchekwa.

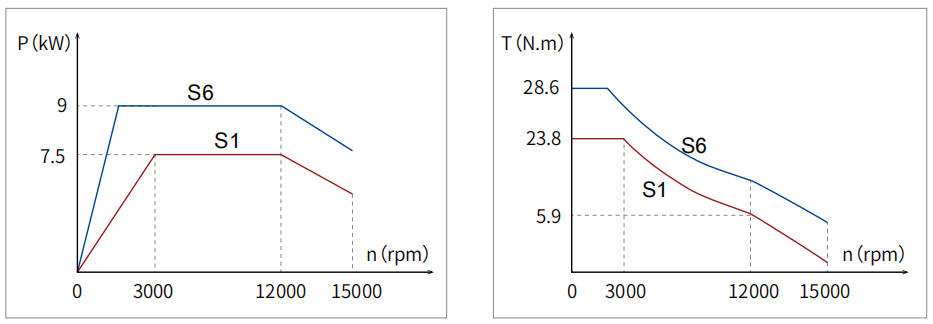

3. Igwe ọkụ eletrik

Mpempe igwe eletrik na-eji mkpịsị aka eletrik arụpụtara onwe ya (patent mepụtara: 202010130049.4), na njedebe na-eji nozzles jụrụ oyi iji mee ka ngwa ahụ dị jụụ. Ọ nwere uru nke elu na-agba, elu nkenke, na elu ike nzaghachi, na ike na-aghọta stepless ọsọ iwu. Ihe ngbanwe dị elu arụnyere n'ime nwere ike ghọta nkwụsịtụ ziri ezi na ịme ọpịpị siri ike.

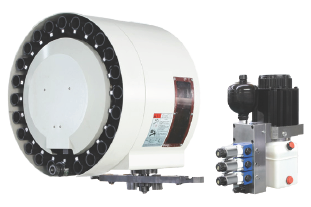

4. Magazin ngwá ọrụ

BT40 diski ụdị akwụkwọ akụkọ, 24 ngwá ọrụ ọnọdụ, akpaka ngwá ọrụ mgbanwe site ATC manipulator.

Hụ okpuru:

5. Turntable

Ọ na-anakwere usoro ihe eji eme ihe n'otu ogwe aka na-eme onwe ya, nke nwere uru dị elu nke siri ike, nkenke dị elu na nzaghachi dị elu.

| Axis | Egotara Torque Nm | Ọnụọsọ ọsọ rpm | Oke. Ọsọ rpm | Enyere aha ugbu a A | Enyere ike kW |

| B | 656 | 80 | 100 | 18 | 5.5 |

| C | 172 | 100 | 130 | 6.1 | 1.8 |

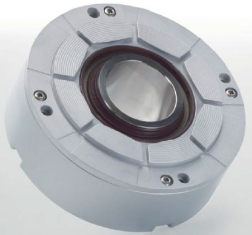

6. Usoro nzaghachi akaghị emechi nke ọma

X, Y, na Z linear axes nwere usoro HEIDENHAIN LC4 zuru oke grating akpịrịkpa; A na-eji tebụl rotary B na C nwere HEIDENHAIN RCN2000 usoro ihe ntinye ọnụ ahịa ọnụ ahịa zuru oke iji nweta nzaghachi mechiri emechi nke axes nri 5, na-ahụ na ngwaọrụ igwe nwere oke nkenke na nkenke dị elu. njide ziri ezi.

7. Igwe oyi na usoro pneumatic

Ejiri ya na igwe nju oyi maka oyi na-ekpo ọkụ mgbe niile iji hụ na spindle eletrik na ntụgharị mbanye ozugbo na-arụ ọrụ nke ọma ma nwee ike na-arụ ọrụ nke ọma ruo ogologo oge.

A na-enyocha usoro pneumatic site na ihe ndị dị na pneumatic iji ghọta ọrụ nke ihicha na ịfụ oghere taper nke isi ihe, mkpuchi mkpuchi ikuku nke isi ihe na-emepụta ihe, na ntụgharị nke akwụkwọ akụkọ ngwá ọrụ na njide ngwá ọrụ.

8. Centralized lubrication usoro

Ihe mgbochi mmịfe nke okporo ụzọ ntuziaka na aku nke ịghasa bọọlụ na-ewere ngwaọrụ mmanye dị n'etiti nwere griiz dị mkpa, nke na-enye mmanu mgbe niile na ọnụọgụ iji hụ na izi ezi na nkwụsi ike nke ịghasa bọọlụ na ụgbọ okporo ígwè.

9. Workpiece nha usoro

Ngwá ọrụ igwe nwere HEIDENHAIN TS460 mmetụ mmetụ na onye na-anata akara ikuku, nke enwere ike itinye ya na spindle site na ntuziaka ma ọ bụ usoro mgbanwe ngwa ngwa iji ghọta ọrụ nke itinye n'ọrụ, nha workpiece na ntọala ntọala, yana nkwughachi nha bụ ≤ 1um (nyocha ọsọ 1 m / min), okpomọkụ na-arụ ọrụ bụ 10 ° C ruo 40 ° C. A na-ebute nyocha mmetụ HEIDENHAIN site na ngbanwe anya. Stylus na-eji akara atọ iji hụ na ọnọdụ steeti n'efu dị mma. Ọ naghị eyi uwe mgbe a na-eji ya eme ihe, ọ na-emegharị ugboro ugboro ma kwụsie ike ruo ogologo oge.

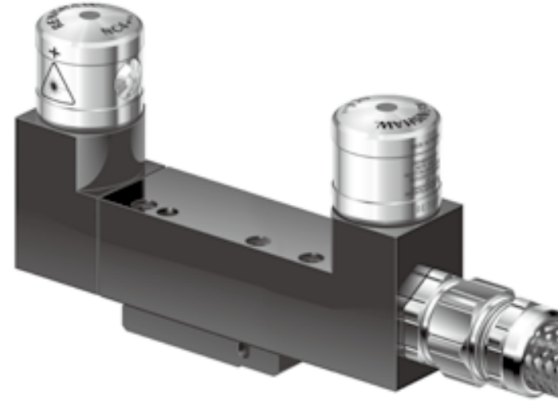

10. Usoro ihe eji eme ihe

Ngwá ọrụ igwe nwere Renishaw NC4 laser ntọala ngwá ọrụ, nha repeatability bụ ± 0.1um, na-arụ ọrụ okpomọkụ bụ 5°C ka 50°C.

11. Ise-axis ziri ezi calibration

Ngwá ọrụ igwe a na-eji bọọlụ calibration KKH sitere na HEIDENHAIN, yana nyocha usoro TS, iji nweta nhazi nkenke nke igwe na-atụgharị axis, belata njehie n'oge mmegharị igwe, wee nweta nkenke zuru oke na nkwughachi dị elu.

12. Nchekwa ngwá ọrụ igwe

Ngwá ọrụ igwe na-anakwere mkpuchi nchebe dị mkpa nke na-ezute ụkpụrụ nchekwa iji gbochie coolant na ibe n'ịfesa, hụ na arụ ọrụ nchekwa, ma nwee ọdịdị mara mma. The X ntụziaka nke igwe ngwá ọrụ na-onwem na ihe agha ọta, nke nwere ike n'ụzọ dị irè na-echebe ụzọ ụgbọ okporo ígwè na bọl ịghasa.

13. Ọnọdụ igwe na-arụ ọrụ

(1) Ike ọkọnọ: 380V± 10% 50HZ± 1HZ atọ-phase AC

(2) Ọnọdụ okpomọkụ: 5°C-40°C

(3) Okpomọkụ kacha mma: 22°C-24°C

(4) iru mmiri dị ala: 20-75%

(5) Ikuku isi iyi: ≥6 mmanya

(6) Ọnụ ọgụgụ isi iyi gas: 500 L / min

14. Ọrụ mmeghe nke usoro CNC

Usoro HEIDENHAIN TNC640 CNC

(1) Ọnụ ọgụgụ nke anyụike: ruo 24 akara loops

(2) Ụdị ihuenyo mmetụ na-arụ ọrụ ọtụtụ aka

(3) Ntinye mmemme: mkparịta ụka Klartext na mmemme G code (ISO).

(4) Mmemme contour n'efu FK: jiri asụsụ mmemme mkparịta ụka Klartext mee mmemme contour n'efu na nkwado eserese.

(5) Oke igwe-egwe ọka na okirikiri olulu mmiri

(6) Nkwụghachi ụgwọ ọrụ: nkwụghachi ụgwọ ọrụ redio na ụgwọ ọrụ ogologo oge. Usoro nyocha

(7) Ịcha data: Mgbakọ akpaaka nke ọsọ spindle, ịcha ọsọ, nri kwa agụba na ndepụta n'otu okirikiri

(8) Constant contour nhazi ọsọ: ikwu na ụzọ nke ngwá ọrụ center / ikwu n'ọnụ ngwá ọrụ

(9) Parallel Run: Mmemme nwere nkwado eserese mgbe mmemme ọzọ na-agba

(10) Ihe nlegharị anya: ahịrị kwụ ọtọ / chamfer / arc ụzọ / okirikiri okirikiri / okirikiri radius / tangentially jikọtara arc / okirikiri okirikiri

(11) Ịbịaru nso na ịpụ na contours: tangential ma ọ bụ perpendicular / site na arc ụzọ

(12) Ihe mmemme na-awụ elu: subroutine/mmemme ngọngọ ikwugharị/mmemme ọ bụla nwere ike ịbụ subroutine

(13) Mkpọ okirikiri: mkpọpu mmiri, ịkụ aka (ya na ma ọ bụ na-enweghị na-ese n'elu mmiri), akụkụ anọ na arc oghere. Mkpọpu ala peck, reaming, na-agwụ ike, ntụpọ chere ihu, ebe egwu egwu. Na-egwe nri ime na mpụta eri. Ebe dị larịị na nke nwere mmasị. Nrụpụta zuru oke nke akpa akụkụ anọ na okirikiri, ndị isi akụkụ akụkụ anọ na okirikiri. Na-agba ọsọ na imecha okirikiri maka uzo kwụ ọtọ na okirikiri. Ntụnye n'usoro na okirikiri na ahịrị. Ebe nhazi: koodu QR. Yinye contour, akpa akpa. Contour groove maka egwe ọka trochoidal. okirikiri ihe osise: kanye ederede ma ọ bụ ọnụọgụ n'ahịrị kwụ ọtọ ma ọ bụ arc.

(14) Ntugharị nhazi: ntụgharị, ntụgharị, enyo, scaling (axis akọwapụtara).

(15) Q parameter variable programming: ịrụ ọrụ mgbakọ na mwepụ, ọrụ ezi uche dị na ya, arụrụ arụ nne nne, uru zuru oke, þ, negation, integer or decimal, ọrụ mgbako okirikiri, ọrụ nhazi ederede.

(16) Ihe enyemaka mmemme: mgbako. Ndepụta ozi njehie niile dị ugbu a. Ọrụ enyemaka nwere mmetụta nke ọnọdụ maka ozi njehie. TNCguide: agbakwunyere usoro enyemaka; TNC 640 na-egosiputa ozi ozugbo site na ntuziaka onye ọrụ. Nkwado eserese maka mmemme okirikiri. Okwu blocks na isi blocks na NC mmemme.

(17) Nnweta ozi: jiri ọnọdụ ahụ kpọmkwem na mmemme NC.

(18) Eserese nkwenye mmemme: Enwere ike ịme ịme anwansị eserese nke arụmọrụ machining ọbụlagodi mgbe mmemme ọzọ na-agba. Nlele elu/nlegharị anya akụkụ atọ / stereo, yana ụgbọ elu nhazi nke nwere mmasị / eserese ahịrị 3-D. Ntụle mpaghara.

(19) Nkwado ndịna-emeputa mmemme: Ọbụlagodi na mmemme ọzọ na-agba ọsọ, enwere ike igosipụta eserese (2-D handwriting tracing diagram) nke ntinye mmemme NC na ọnọdụ ọrụ ndezi mmemme.

(20) Eserese mmemme na-agba ọsọ: ịme anwansị eserese nke oge mgbe ị na-eme mmemme igwe nri. nlele elu/nlegharị anya atọ / stereo.

(21) Oge nhazi: Gbakọọ oge nhazi na ọnọdụ ọrụ "ule ọsọ". Na-egosiputa oge nhazi nke ugbu a na "Program Run" mode arụ ọrụ.

(22) Laghachi na contour: gosipụta oge nhazi ugbu a na ọnọdụ ọrụ "mmemme na-agba ọsọ". Nkwụsị mmemme, ịpụ na ịlaghachi na contour.

(23) Nlekọta ihe nhazi nke mbụ: tebụl maka ịchekwa ebe ọ bụla atọrọ.

(24) Origin table: multiple si malite tebụl, na-eji zọpụta ikwu si malite workpiece.

(25) Nrụpụta 3-D: Njikwa ngagharị nke ezigbo Jerk dị mma

(26) Oge nhazi ngọngọ: 0.5 ms

(27) Mkpebi ntinye na nzọụkwụ ngosi: 0.1 μm

(28) Ogologo okirikiri: nhazi nyocha. Akwụkwọ ntuziaka ma ọ bụ akpaka ugwo nke workpiece ezighị ezi. Jiri aka ma ọ bụ na-akpaghị aka tọọ ihe atọrọ atọ. Ngwá ọrụ na workpiece nwere ike tụrụ na-akpaghị aka.

(29) Nkwụghachi ụgwọ mperi: njehie axis linear na nke na-abụghị nke na-adịghị, azụ azụ, ntụgharị ihu dị nkọ nke mmegharị okirikiri, njehie ntụgharị, mgbasawanye ọkụ. esemokwu static, esemokwu na-amị amị.

(30) Data interface: RS-232-C/V.24, ruo 115 kbit/s. Ntugharị data agbatịkwuru nke protocol LSV2, jiri HEIDENHAIN TNCremo ma ọ bụ sọftụwia TNCremoPlus iji rụọ ọrụ TNC n'ime anya site na interface data a. 2 x Gigabit Ethernet 1000BASE-T interface. 5 x USB ọdụ ụgbọ mmiri (1 n'ihu USB 2.0 ọdụ ụgbọ mmiri, 4 USB 3.0 ọdụ ụgbọ mmiri).

(31) Nchọpụta nchọpụta: Ngwaọrụ nyocha nke nwere onwe maka ngwa ngwa na nke dabara adaba.

(32) Onye na-agụ CAD: gosipụta faịlụ usoro CAD ọkọlọtọ.

Isi oke

| Ihe | Nkeji | Oke | |

| Tebụl arụ ọrụ | dayameta arụ ọrụ | mm | 320 |

| Ibu kehoraizin kacha | kg | 150 | |

| Ibu vetikal kacha | kg | 100 | |

| T-oghere | mm | 8X10H8 | |

| Oke nhazi | Ọdị anya n'etiti ihu ngwụcha spindle na ihu ngwụcha ọrụ (Max) | mm | 430 |

| Ọdị anya n'etiti ihu ngwụcha spindle na ihu ngwụcha ọrụ (Min) | mm | 100 | |

| Akụkụ X | mm | 450 | |

| Y axis | mm | 320 | |

| Axis Z | mm | 330 | |

| B axis | ° | -35°~+ 110° | |

| C axis | ° | 360° | |

| Spindle | Taper (7 ∶ 24) |

| BT40 |

| Enyere ọsọ ọsọ | rpm | 3000 | |

| Oke. ọsọ | rpm | 15000 | |

| Obere ike S1 | Nm | 23.8 | |

| Enyere ike S1 | KW | 7.5 | |

|

Axis | X axis na-agafe ọsọ ọsọ ọsọ | m/min | 36 |

| Y axis ngwa ngwa gafere ọsọ | m/min | 36 | |

| Z axis na-agafe ọsọ ọsọ ọsọ | m/min | 36 | |

| B axis Max. ọsọ | rpm | 130 | |

| C axis Max. ọsọ | rpm | 130 | |

| Magazin ngwaọrụ | Ụdị |

| Ụdị diski |

| Usoro nhọrọ ngwaọrụ |

| Nhọrọ ngwaọrụ bidirectional kacha nso | |

| Ike | T | 24 | |

| Oke. ogologo ngwá ọrụ | mm | 150 | |

| Oke. arọ ngwá ọrụ | kg | 7 | |

| Oke. dayameta diski cutter (Ngwaọrụ zuru oke) | mm | 80 | |

| Dayameta diski kacha elu (ngwaọrụ efu efu n'akụkụ) | mm | 150 | |

| izi ezi | Ụkpụrụ isi |

| GB/T20957.4(ISO10791-4) |

| Akwụsị X-axis/Y-axis/Z-axis nhazi ziri ezi | mm | 0.008/0.008/0.008 | |

| B-axis/C-axis idobe izi ezi |

| 7"/7" | |

| X-axis/Y-axis/Z-axis na-ekwughachi izi ezi n'ọnọdu | mm | 0.006/0.006/0.006 | |

| B-axis/C-axis kwugharịa n'ọnọdu izi ezi |

| 5"/5" | |

| Ibu igwe | Kg | 5000 | |

| Mkpokọta ikike eletriki | KVA | 45 | |

Ndepụta nhazi ọkọlọtọ

| Mba. | Aha |

| 1 | Ihe ndị bụ isi (gụnyere akwa, kọlụm, efere slide, oche slide, oche oche) |

| 2 | X, Y, Z sistemu nri axis atọ |

| 3 | Otu ihe eji eji obere ogwe aka tụgharịa |

| 4 | Igwe ọkụ eletrik BT40 |

| 5 | Usoro njikwa eletriki (gụnyere kabinet eletriki, modul ọkọnọ ọkụ, modul servo, PLC, panel panel, ngosi, ihe eji eme ihe, igwe ikuku ikuku, wdg) |

| 6 | Ọnụ ọgụgụ nke grading: HEIDENHAIN |

| 7 | Sistemụ hydraulic |

| 8 | Sistemụ pneumatic |

| 9 | Sistemụ mmanye mmanye nke etiti |

| 10 | Ihe ebufe mgbawa, tank mmiri, onye na-anakọta mgbawa |

| 11 | Onye nche ụgbọ oloko |

| 12 | Ngwá ọrụ igwe n'ozuzu mkpuchi mkpuchi |

| 13 | Ngwaọrụ na-atụ ihe arụ ọrụ: HEIDENHAIN TS460 |

|

| Akara akpịrịkpa HEIDENHAIN |

| 14 | Ngwa ntọala ngwaọrụ: HEIDENHAIN NC4 |

| 15 | Nhazi nhazi nkenke axis ise: HEIDENHAIN KKH |

| 16 | Dabere n'otu ebe eji HPMILL ngwa ngwa nhazi nhazi, kechie adreesị anụ ahụ nke kọmputa ahụ |

| 17 | Spindle thermal elongation akwụ ụgwọ ọrụ |