BOSM -12010 Igwe ihe igwe na-agwụ ike nke isi

1. Ojiji nkeigwe :

BOSM- 12000* 1000 ofu-beam CNC gantry abụọ kọlụm isi-na-isi na-agwụ ike na-egwe ọka igwe bụ a pụrụ iche igwe ngwá ọrụ maka nhazi excavator ogwe aka / osisi. Ohiri isi, nwere ike na-aghọta ngwa ngwa nhazi nke workpiece, workpiece nwere ike gbapuo, milled, na-agwụ ike n'ime irè ọrịa strok nso, na workpiece nwere ike hazie na ebe n'otu oge (ọ dịghị mkpa nke abụọ clamping), na loading na ebutu ọsọ. dị ngwa ngwa, ọnọdụ ọnọdụ dị ngwa ngwa, na nhazi nhazi dị elu. Nrụ ọrụ nhazi dị elu, dị elu.

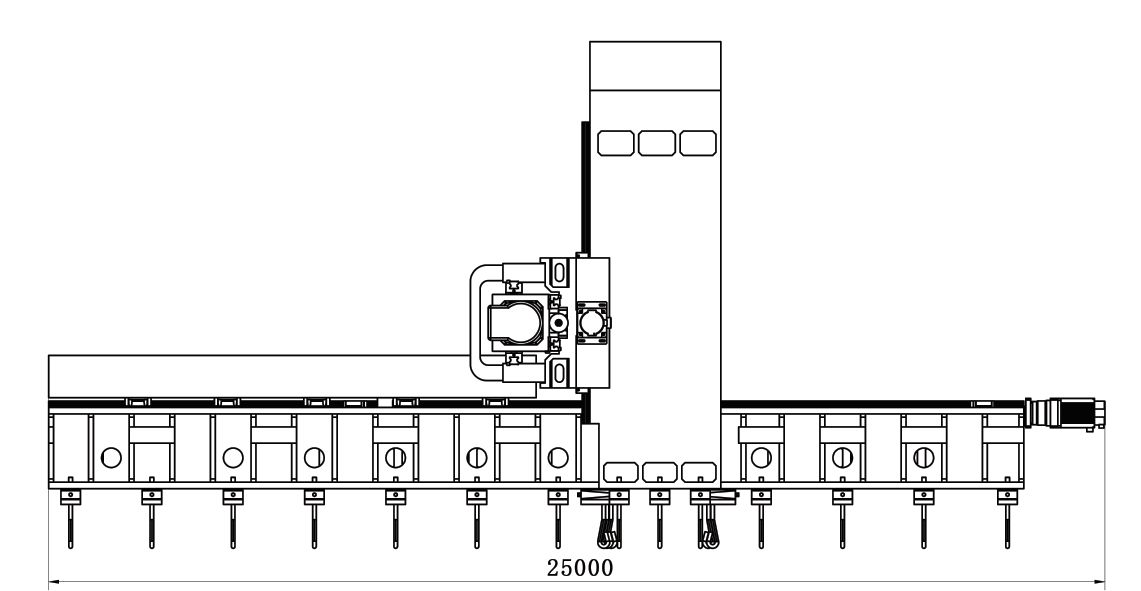

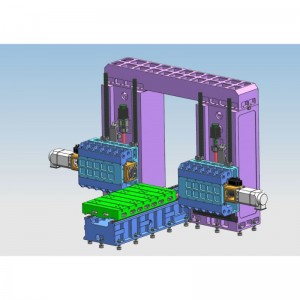

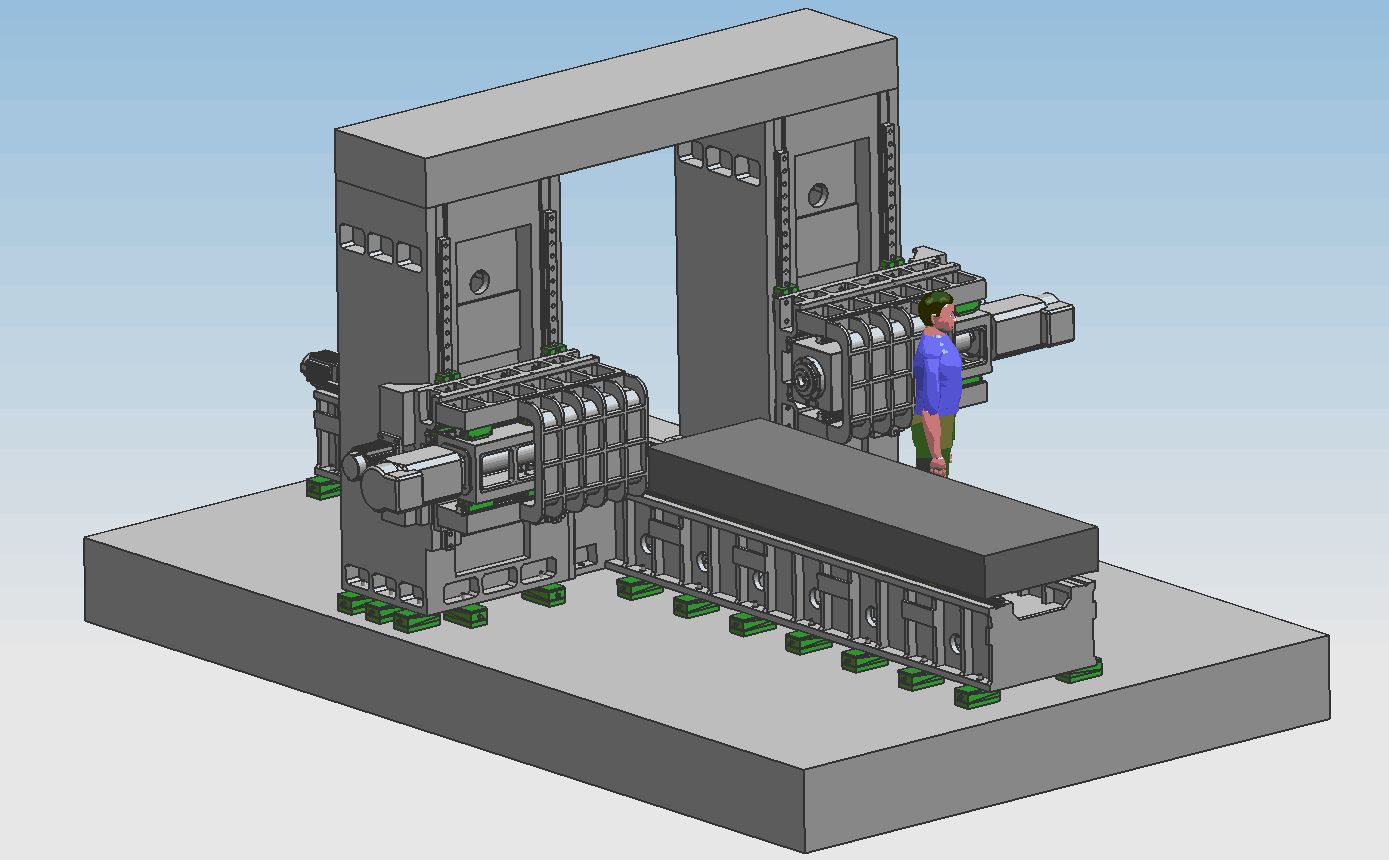

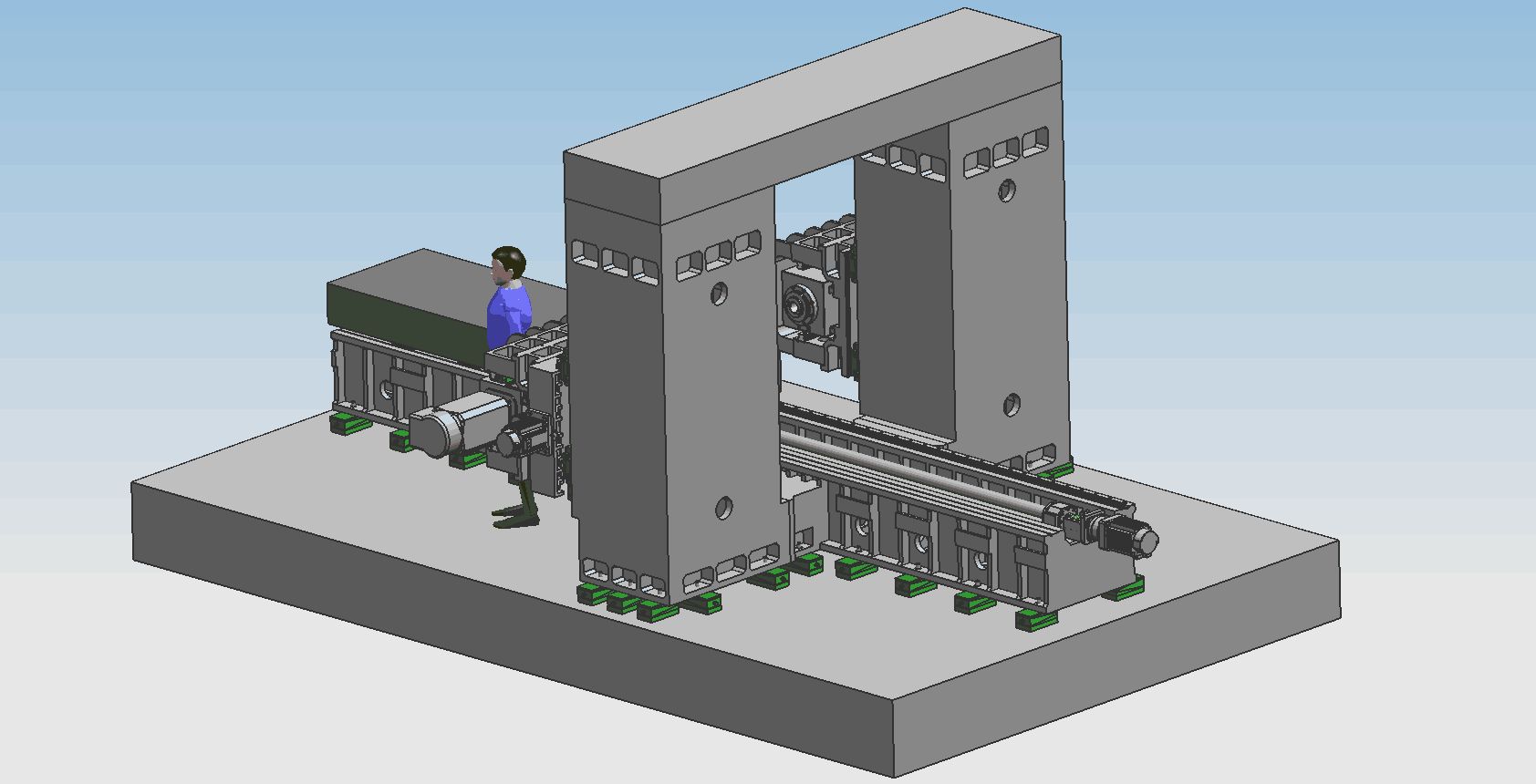

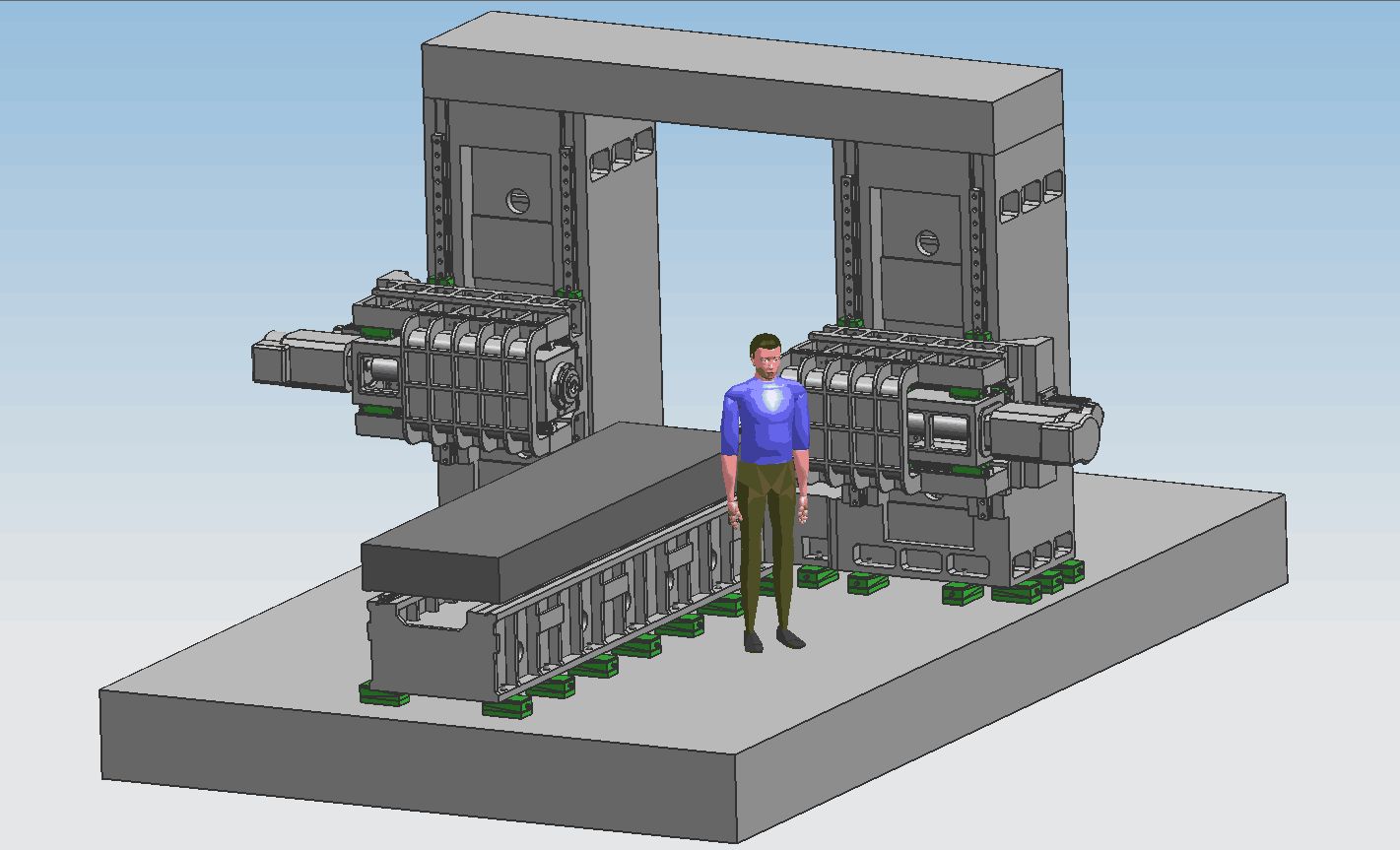

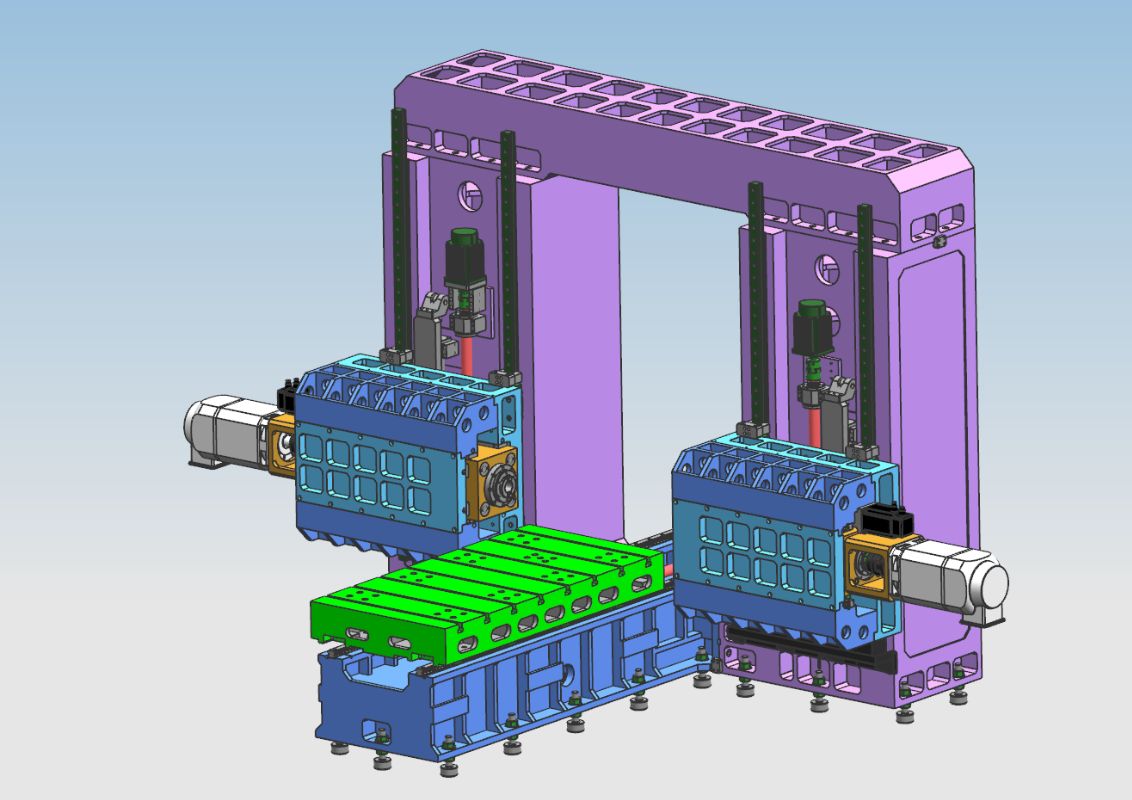

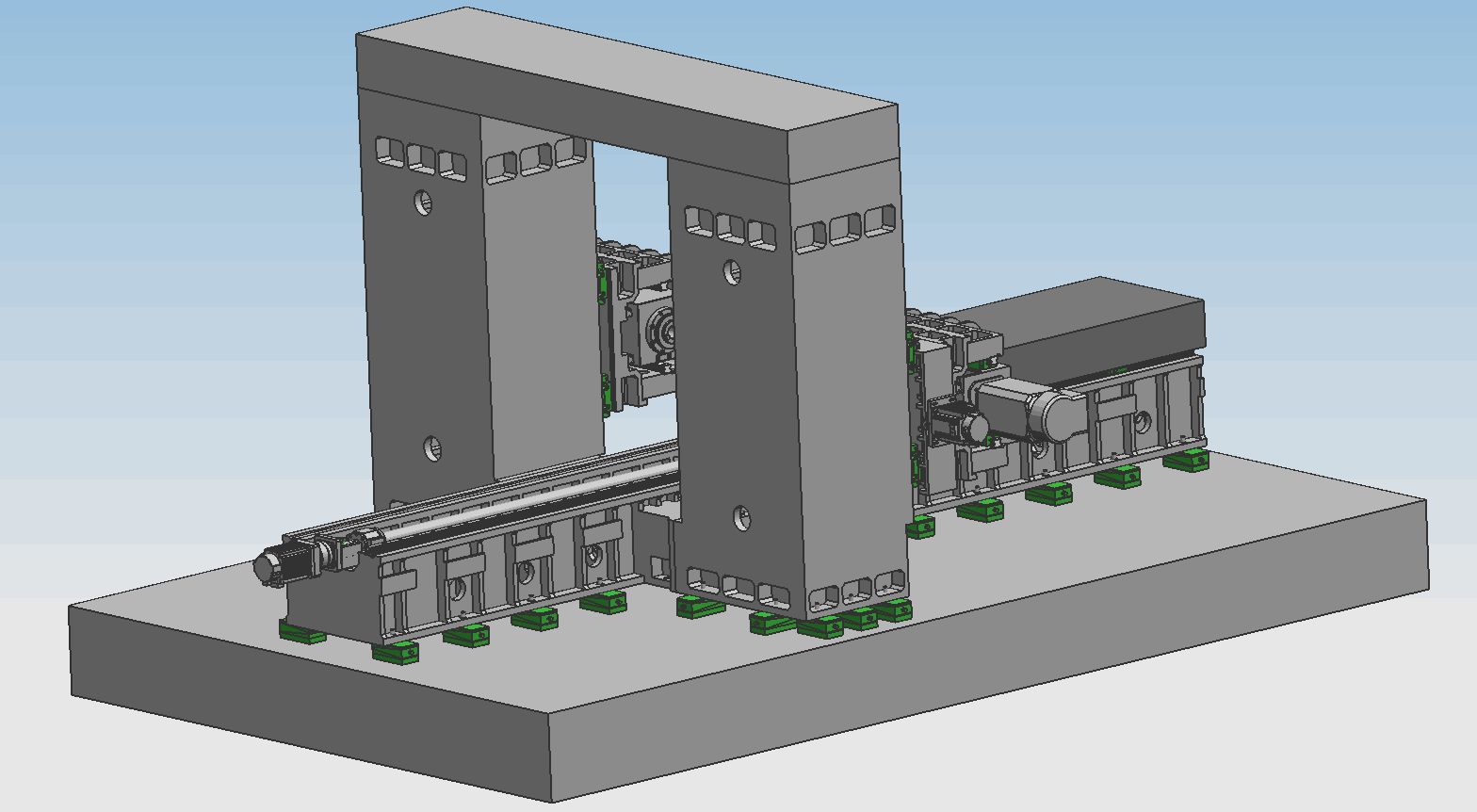

2.Ọdịdị igweatụmatụ:

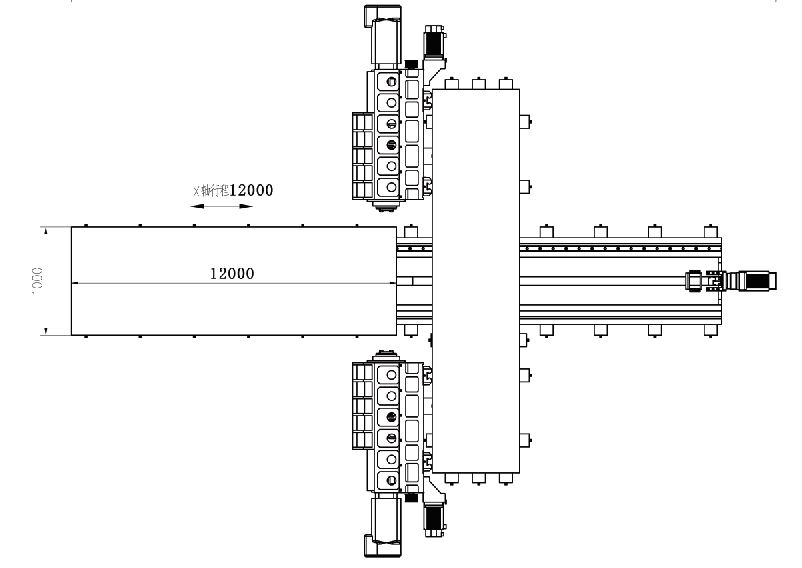

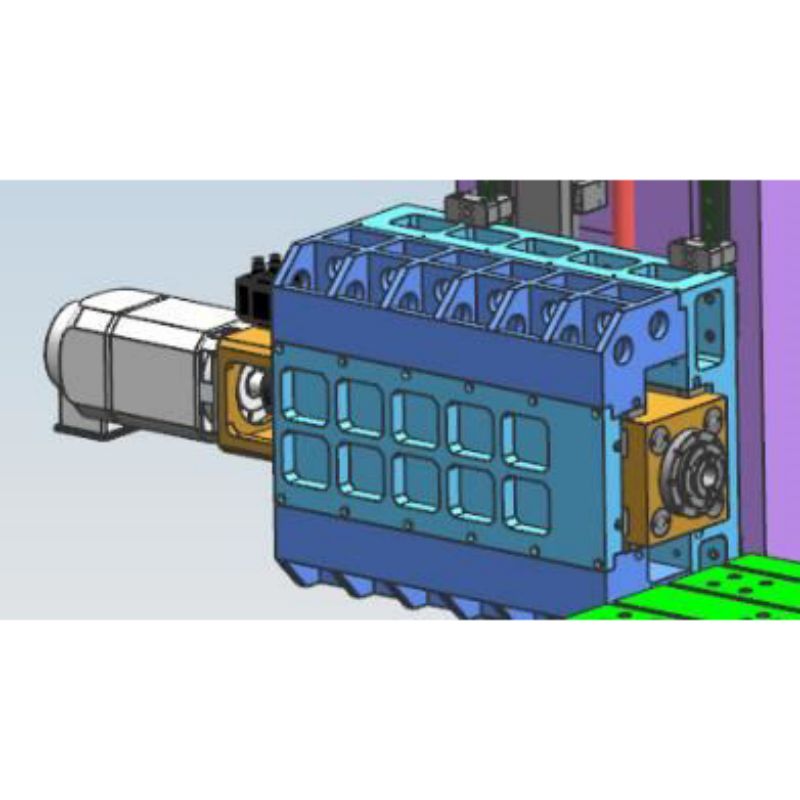

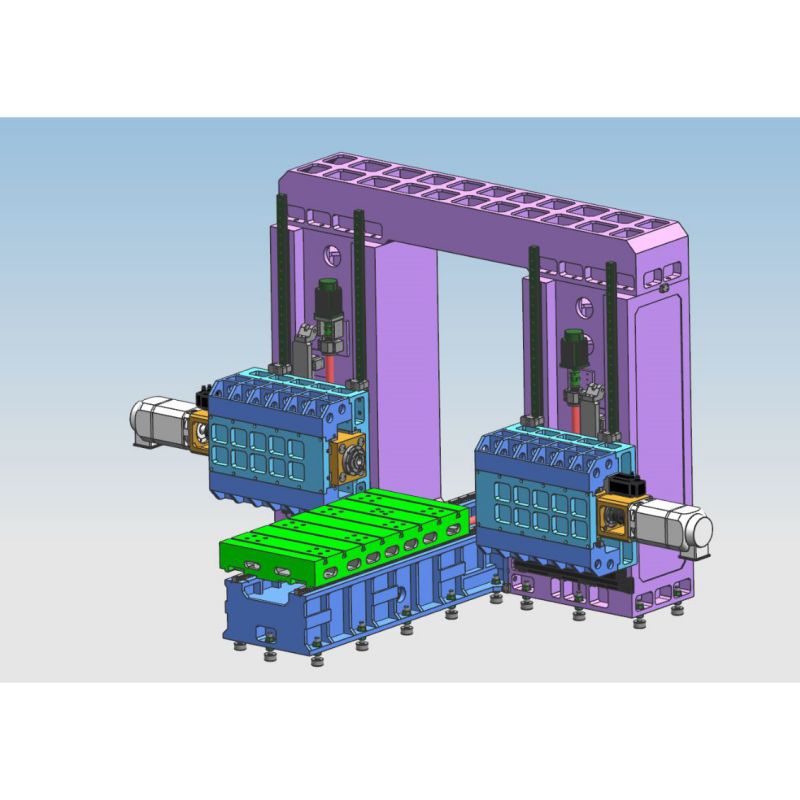

Ihe ndị bụ isi nke ngwá ọrụ igwe: akwa, workbench, ogidi aka ekpe na aka nri, ogwe osisi, gantry na-ejikọta osisi, saddles, ebulu, wdg, nnukwu akụkụ na-eme ka nke resin ájá ịkpụzi, elu-edu isi awọ ígwè 250 nkedo, annealed na-ekpo ọkụ. ájá olulu → vibration ịka nká → ọgwụgwọ okpomọkụ ọkụ annealing → vibration ịka nká → siri ike machining → vibration ịka nká → ọkụ ọkụ annealing → vibration ịka nká → imecha, kpamkpam kpochapụ nrụgide na-adịghị mma nke akụkụ ahụ, ma mee ka arụmọrụ nke akụkụ ahụ kwụsie ike. Ihe ndina edoziri, ogidi aka ekpe na aka nri, gantry, na workbench na-agagharị; Ọ nwere ọrụ nke igwe-egwe ọka, na-agwụ ike, mkpọpu ala, countersinking, tapping, wdg The ngwá ọrụ jụrụ usoro bụ mpụga jụrụ . Ngwá ọrụ igwe nwere 5 axes nri, nke nwere ike ịghọta njikọ 4-axis na 5-axis single-action. Enwere isi ike 2. E gosipụtara axis nke ngwá ọrụ igwe na isi ike na foto dị n'okpuru.

2.1.Isi ihe owuwu nke akụkụ nri nnyefe axial

2.1.1.Axis X:Tebụl ọrụ ahụ na-emegharị azụ n'akụkụ okporo ụzọ nduzi nke akwa akwa.

X 1-axis mbanye: AC servo moto gbakwunyere onye na-ebelata mbara ala dị elu bụ nke na-ebugharị bọọlụ na-ebugharị mmegharị nke workbench iji ghọta mmegharị ahịrị nke X-axis.

Ụdị ụgbọ okporo ígwè nduzi: tọọ okporo ụzọ ụzọ ziri ezi ziri ezi dị elu.

2.1.2 Z1 axis:A na-etinye isi ike na sadulu kwụ ọtọ n'akụkụ ihu nke kọlụm ahụ, na-emegharị elu na ala n'akụkụ okporo ụzọ kọlụm.

Mbufe Z1-axis: A na-eji AC servo moto na wheel synchronous mee ihe iji kwọọ skru bọọlụ iji kwọọ sadulu iji ghọta mmegharị ahịrị nke Z-axis.

2.1.3 Z2 axis:A na-etinye isi ike na sadulu kwụ ọtọ n'akụkụ ihu nke kọlụm ahụ, na-emegharị elu na ala n'akụkụ okporo ụzọ kọlụm.

Mbufe Z2-axis: A na-eji AC servo moto na wheel synchronous iji kwọọ skru bọọlụ iji kwọọ sadulu iji ghọta ngagharị linear Z-axis.

2.1.4 Y1 axis:A na-etinye sadulu isi ike kwụ ọtọ n'akụkụ ihu nke kọlụm aka nri, ma na-emegharị aka ekpe na aka nri n'akụkụ okporo ụzọ kọlụm.

Mfefe Y1-axis: AC servo moto gbakwunyere mbelata mbara ala dị elu ka a na-eji ebu ebu ahụ ka ọ gafere n'akiri bọọlụ iji ghọta mmegharị ahịrị nke Y1-axis.

2.1.5 Y2 axis:A na-etinye sadulu isi ike kwụ ọtọ n'akụkụ ihu nke kọlụm aka nri, ma na-emegharị aka ekpe na aka nri n'akụkụ okporo ụzọ kọlụm.

Mbufe Y2-axis: AC servo moto gbakwunyere mbelata mbara ala dị elu ka a na-eji akwọ ebule ahụ ka ọ gafee bọọlụ bọọlụ iji ghọta mmegharị ahụ Y2-axis linear.

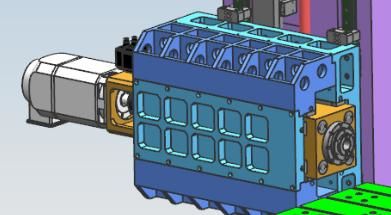

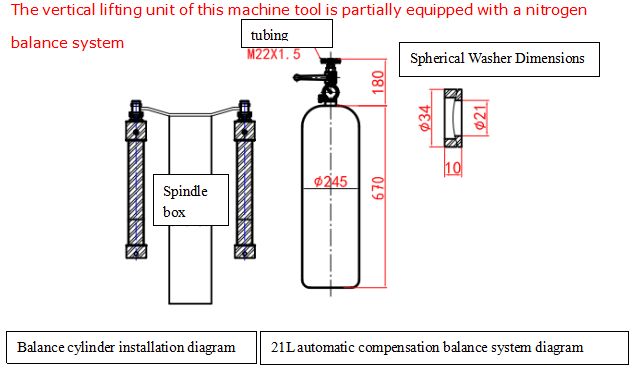

2.2.Ntuziaka na-akpụ akpụ nke isi mgbapu na igwe igwe (gụnyere isi ike 1 na 2) na-agbaso usoro ebule square, usoro ụzọ ụgbọ okporo ígwè jikọtara waya siri ike, okporo ụzọ siri ike gbara ya gburugburu site na nkwado siri ike, 4 linear roller ndu okporo ígwè. A na-eduzi ụzọ abụọ, draịva ahụ na-ejikwa AC servo moto Drive na eriri synchronous (i=2) na nnyefe bọọlụ ziri ezi, isi ike na-eji moto servo ka ọ daa site na eriri synchronous na wheel synchronous, na-eduzi nkenke nke oke ọrụ. ndu okporo ígwè ụzọ, na draịva na vetikal bọl ịghasa na-bugharia, aghọta ike isi Do elu na ala vetikal ije , na onwem na nitrogen itule mmanya iji belata ibu ikike nke igwe isi na ịghasa na servo moto. Moto Z-axis nwere ọrụ breeki akpaka. N'ihe gbasara ọdịda ike, breeki akpaka ga-ejide ogwe moto ahụ nke ọma. , ka ọ ghara ibugharị. Mgbe ị na-arụ ọrụ, mgbe mkpọkuku adịghị emetụ workpiece, ọ ga-eri nri ngwa ngwa; mgbe akuakuzinwo bit metụrụ workpiece, ọ ga-akpaghị aka ịgbanwee na-arụ ọrụ ndepụta. Mgbe akuakuzinwo bit banye workpiece, ọ ga-akpaghị aka ịgbanwee ngwa ngwa rewind; mgbe ọgwụgwụ nke akuakuzinwo bit doo workpiece na esịmde set ọnọdụ, na worktable ga-akpali na-esote oghere ọnọdụ ịghọta akpaka mgbasa. Isi ike na-ejikọta njikọ nke waya na ụgbọ okporo ígwè siri ike, nke ọ bụghị nanị na-eme ka ngwa ngwa na-agba ọsọ nke ngwa ahụ, kamakwa na-eme ka ihe siri ike nke ngwá ọrụ dịkwuo elu. Ma ọ nwere ike ghọta ọrụ nke mkpọpu oghere kpuru, igwe igwe, chamfering, mgbawa mgbawa, iwepụ mgbawa akpaka, wdg, nke na-eme ka nrụpụta ọrụ dịkwuo mma.

(isi ike aka ekpe)

2.3. Mwepụ mgbawa na jụrụ oyi

A na-ebugharị ihe mgbawa okirikiri na ewepụghị n'akụkụ abụọ dị n'okpuru ebe a na-arụ ọrụ, enwere ike ịgbanye ibe ya na ebufe mgbawa na njedebe site na ọkwa abụọ nke gburugburu na efere agbụ iji ghọta mmepụta mmepeanya. Enwere mgbapụta dị jụụ na tankị jụrụ oyi nke ihe mgbawa mgbawa, nke enwere ike iji mee ka ọ dị jụụ nke ngwá ọrụ iji hụ na arụ ọrụ ịkụ ala na ndụ ọrụ nke ihe ọkụkụ ahụ, na oyi nwere ike ịmegharị ya.

3.Sistemụ njikwa ọnụọgụ dijitalụ zuru oke:

3.1.Site n'iji arụ ọrụ mgbawa mgbawa, oge nkwụsị mgbawa na mgbawa mgbawa nwere ike ịtọ na interface nke igwe.

3.2.Site na ọrụ ebuli ngwá ọrụ, ngwá ọrụ na-ebuli elu nwere ike ịtọ na interface nke igwe-igwe. Mgbe mkpọpu ihe ruru elu a, a na-ebuli ngwa ngwa a na-ebuli elu n'elu ọrụ ahụ, mgbe ahụ, a na-atụfu ibe ndị ahụ, na-ebugharị ngwa ngwa n'elu ebe a na-egwupụta ihe na-akpaghị aka na-arụ ọrụ.

3.3.Igbe njikwa ọrụ Centralized na ngalaba ejiri aka na-agbaso usoro njikwa ọnụọgụ ma kwadebere ya na interface USB na ngosipụta kristal mmiri mmiri LCD. Iji kwado mmemme, nchekwa, ngosi na nkwurịta okwu, interface ọrụ nwere ọrụ dị ka mkparịta ụka nke igwe mmadụ, nkwụghachi ụgwọ njehie, na mkpu na-akpaghị aka.

3.4.Ngwá ọrụ ahụ nwere ọrụ nke ịhụchalụ na nyochaghachi ọnọdụ oghere tupu nhazi ya, ọrụ ahụ dịkwa mma.

4. Mmanu akpaaka

Machine ngwá ọrụ nkenke linear ndu okporo ígwè ụzọ abụọ, nkenke bọọlụ ịghasa ụzọ abụọ na ndị ọzọ elu-nkenke ngagharị ụzọ abụọ na-onwem na akpaka lubrication usoro. Igwe mgbapụta mmanụ na-akpaghị aka na-emepụta mmanụ nrụgide, na ọnụ ụlọ mmanụ lubricator quantitative na-abanye na mmanụ. Mgbe ụlọ mmanụ jupụtara na mmanụ, mgbe nrụgide usoro na-ebili na 1.4-1.75Mpa, a na-emechi ngbanwe nrụgide na usoro ahụ, mgbapụta ahụ na-akwụsị, na valvụ na-ebupụ na-ebupụ n'otu oge ahụ. Mgbe nrụgide mmanụ dị n'okporo ụzọ dara n'okpuru 0.2Mpa, mmanụ aṅụ na-amalite imeju ebe a na-ete mmanụ ma mechaa otu njuputa mmanụ. N'ihi mmanye mmanụ ziri ezi nke injector mmanụ ọnụ ọgụgụ na nchọpụta nke nrụgide usoro, mmanụ mmanụ a pụrụ ịdabere na ya, na-ahụ na e nwere ihe nkiri mmanụ n'elu nke ọ bụla kinematic pair, na-ebelata esemokwu na iyi, na igbochi mmebi ahụ. Ọdịdị dị n'ime ya kpatara oke ọkụ. , iji hụ na izi ezi na ndụ nke igwe igwe. E jiri ya tụnyere ụzọ ụgbọ okporo ígwè na-agbagharị agbagharị, ụzọ ụgbọ okporo ígwè na-agbagharị agbagharị ejiri na ngwa igwe a nwere ọtụtụ uru:

①Mmetụta mmegharị ahụ dị elu, ọnụọgụ esemokwu nke ụgbọ okporo ígwè na-atụgharị bụ obere, naanị 0.0025 ~ 0.01, na ike ịnya ụgbọ ala na-ebelata nke ukwuu, nke bụ naanị 1/10 nke igwe nkịtị.

② Ọdịiche dị n'etiti esemokwu dị ike na nke static dị ntakịrị, yana arụmọrụ na-esochi ya dị oke mma, ya bụ, oge etiti oge n'etiti mgbaàmà ịnya ụgbọ ala na ihe eji arụ ọrụ dị mkpụmkpụ, nke na-eme ka ọ dịkwuo mma iji meziwanye ọsọ nzaghachi na nghọta nke usoro njikwa ọnụọgụgụ.

③Ọ dabara maka ngagharị kwụ ọtọ dị elu, ọsọ ya ozugbo dị ihe dị ka ugboro 10 karịa nke okporo ụzọ ntuziaka na-amị amị.

④ Ọ nwere ike ịghọta mmegharị na-enweghị oghere ma melite mmegharị ahụ siri ike nke sistemụ igwe.

⑤ Ndị ọkachamara na-emepụta ihe na-emepụta, ọ nwere nhazi dị elu, ịdị mma dị mma na nhazi dị mfe.

5. gburugburu eji igwe:

Ike ọkọnọ: atọ-adọ AC380V ± 10% , 50Hz ± 1 Ambient okpomọkụ: 0 ° ~ 45 °

Ise, isi teknuzu paramita:

6. Usoro nka

| Nlereanya | BOSM12010 | |

| Oke nhazi workpiece size | Ogologo × obosara × ịdị elu (mm) | 12000×1000×1500 |

| Dayameta Cutter kacha | 200mm | |

| Gantry kacha ndepụta | Obosara (mm) | 1300 |

| arụ ọrụ oche size | Ogologo X Ogologo (mm) | 12000*1000 |

|

Okirikiri ebule ụdị mkpọpu isi ike isi otu abụọ

| Ọnụọgụ (2) | 2 |

| Spindle taper | BT50 | |

| Dayameta mkpọpu mmiri (mm) | Φ2-Φ60 | |

| Dayameta ịpị (mm) | M3-M30 | |

| Ọsọ spindle (r/min) | 30-6000 | |

| Servo spindle moto ike (kw) | 37 | |

| Ogologo imi site na etiti okpokoro (mm) | 150-650 | |

| Ụkwụ aka ekpe na aka nri nke otu ebule (mm) | 500 | |

| Ebe dị anya n'etiti etiti ebule na ụgbọ elu nke tebụl (mm) | 200-1700 | |

| Mgbago elu na ala nke ebule (mm) | 1500 | |

| Nkwagharị ugboro ugboro | 300mm * 300mm | ±0.02 |

| Akụkụ Ngwá Ọrụ Machine | Ogologo × obosara × ịdị elu (mm) | dị ka eserese |

| Nnukwu ibu (t) | (ihe dị ka) 62 | |

Paragraf ndị a dị n'elu bụ paramita nhazi nke mbido. Na n'ezie imewe, e nwere ike mgbanwe dị ka nhazi chọrọ nke workpiece na imewe chọrọ nke igwe ngwá ọrụ, ka izute chọrọ gị ụlọ ọrụ nhazi akụkụ.