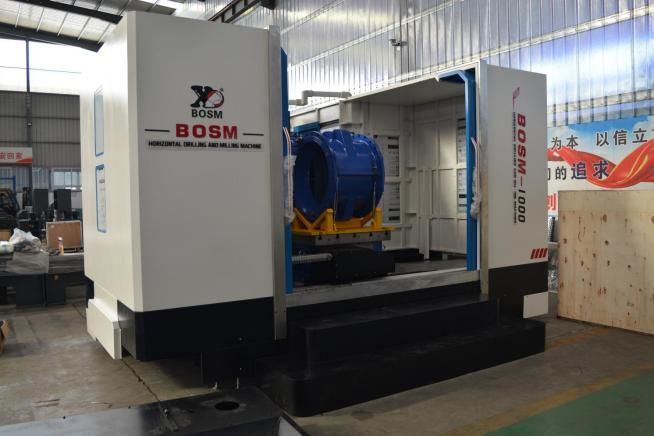

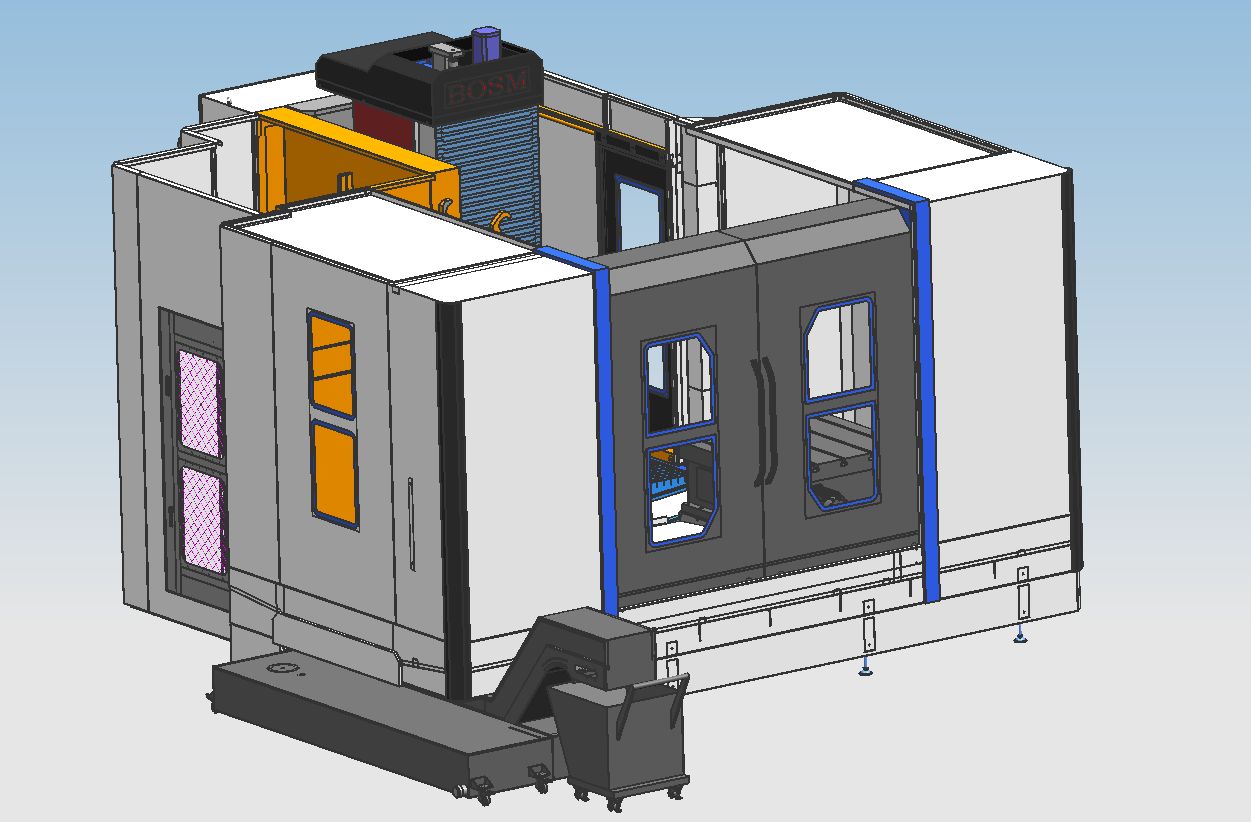

BOSM -4Z2000 Igwe na-egwupụta ihe na igwe igwe CNC dị elu

1.Equipment eji:

A na-eji BOSM-1000 kwụ ọtọ CNC mkpọ ala na igwe igwe igwe maka ọtụtụ akụkụ dị mma nke mkpọpu ala, igwe igwe, ịme ọpịpị na nhazi nke valves, ihe mgbochi valvụ, ndị na-ebelata, flanges, diski, mgbanaka, nkwado slewing na ndị ọzọ workpieces n'ime irè nso nke ọkpụrụkpụ. . Enwere ike ịkwọ ụgbọ mmiri, igwe igwe, ịkụ aka na ịgwụ ike n'otu akụkụ ihe na ihe mejupụtara. A na-achịkwa usoro nhazi nke igwe igwe, na ọrụ ahụ dị nnọọ mma. Ọ nwere ike na-aghọta akpaaka, elu nkenke, multi-iche na uka mmepụta.

2. Nhazi akụrụngwa:

Nke a akụrụngwa bụ tumadi mejupụtara bed, CNC indexing rotary table, ibughari kọlụm, ibughari sadulu, mkpọpu ala na-egwe ọka isi ike, akpaka lubrication ngwaọrụ na nchedo ngwaọrụ, ikesa jụrụ oyi ngwaọrụ, dijitalụ akara usoro, hydraulic usoro, eletriki usoro na na. A na-akwado ma na-eduzi ụgbọ okporo ígwè na-agbagharị agbagharị, ma na-ebugharị nkenke nkenke. Igwe ahụ nwere ezi nguzozi dị elu ma kwugharịa izi ezi n'ọnọdu.

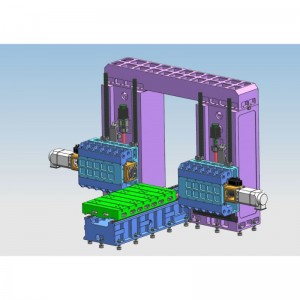

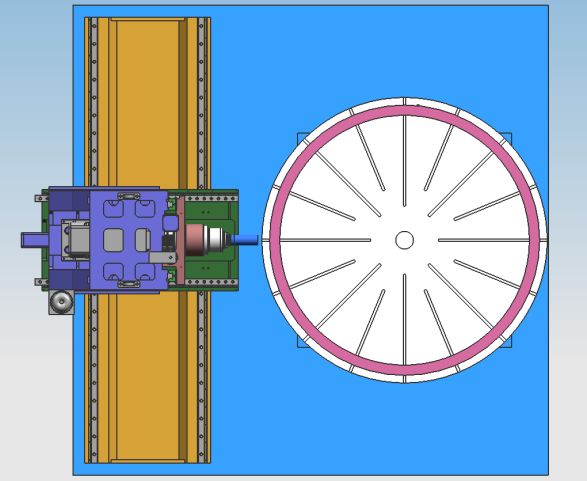

2.1. Ihe ndina na-arụ ọrụ: Ihe ndina bụ akụkụ nhazi igwe nkedo HT250. A na-emecha ya mgbe iwe ọkụ nke abụọ gasịrị iji wepụ nrụgide dị n'ime. Ọ nwere ezigbo ike na static rigidity na ọ dịghị deformation. Mpempe akara akara ọnụọgụ nkenke, servo drive 360º indexing indexing na mkpuchi ikuku / hydraulic, sistemu draịva na-eji AC servo moto na-egosipụta akụkụ akụkụ 360 na-atụgharị na-akpaghị aka, yana izi ezi nke ndenye aha bụ otu puku nke ogo. A na-etinye efere indexing n'elu ihe ndina ahụ, a na-ekesakwa bolts na-agbanwe agbanwe na ala nke ihe ndina, nke nwere ike ịhazigharị ọkwa nke ihe ndina na-arụ ọrụ ngwa ngwa.

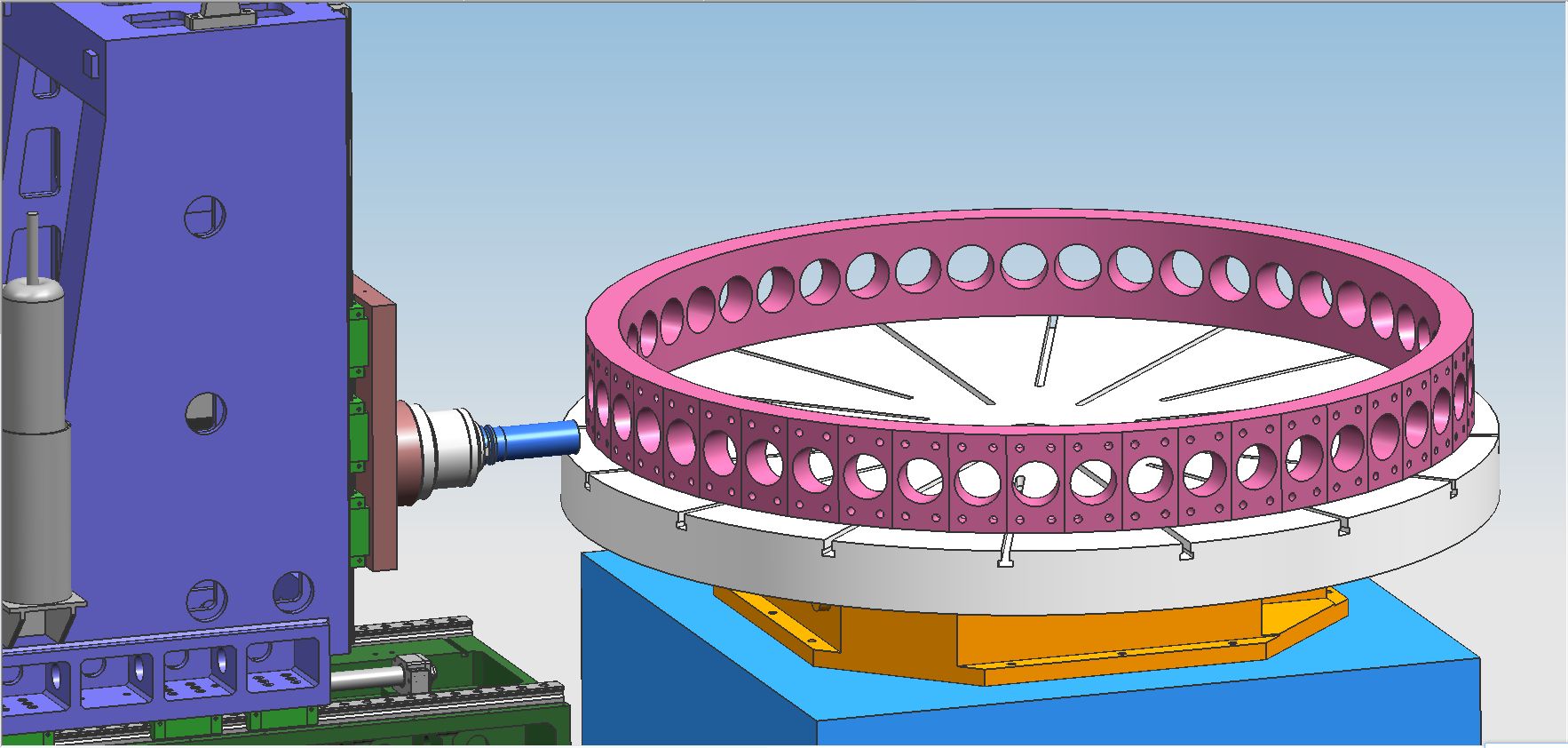

2.2. Kọlụm enwere ike ibugharị: kọlụm nhazi ihe nkedo a na-ebugharị agwụ ka emechara ọgwụgwọ iwe ọkụ nke abụọ iji wepụ nrụgide dị n'ime. Ọ nwere ezigbo ike na static rigidity na ọ dịghị deformation. Otu ụzọ mkpirisi bọọlụ ziri ezi na moto servo na-eme ka slide kọlụm na-aga na ntụzịaka Y-axis. Otu ụzọ mkpirisi bọọlụ ziri ezi na moto servo na-eme ka slide kọlụm na-aga na ntụzịaka axis X. Wụnye otu mgbapu ihe na slide unit. A na-enweta mmegharị nke kọlụm site na ntụgharị nke mkpụrụ akụ na bọọlụ nke servo moto na-ebugharị site na njikọta.

2.3. Sadụl mkpanaka: Sadụl mkpanaka nwere ihe abụọ dị elu na-ebu ikike na-ebugharị ụzọ ụzọ ụzọ ụgbọ okporo ígwè, otu ụzọ mgbagha bọọlụ ziri ezi na moto servo, nke na-eme ka isi ike igwu mmiri gaa na ntụzịaka Z-axis, nke nwere ike. ghọta Ike isi ngwa ngwa na-aga n'ihu, na-arụ ọrụ na-aga n'ihu, ntụgharị ngwa ngwa, nkwụsị na omume ndị ọzọ. Ọ nwere ọrụ nke mgbawa mgbawa akpaka, iwepụ mgbawa na kwụsịtụ.

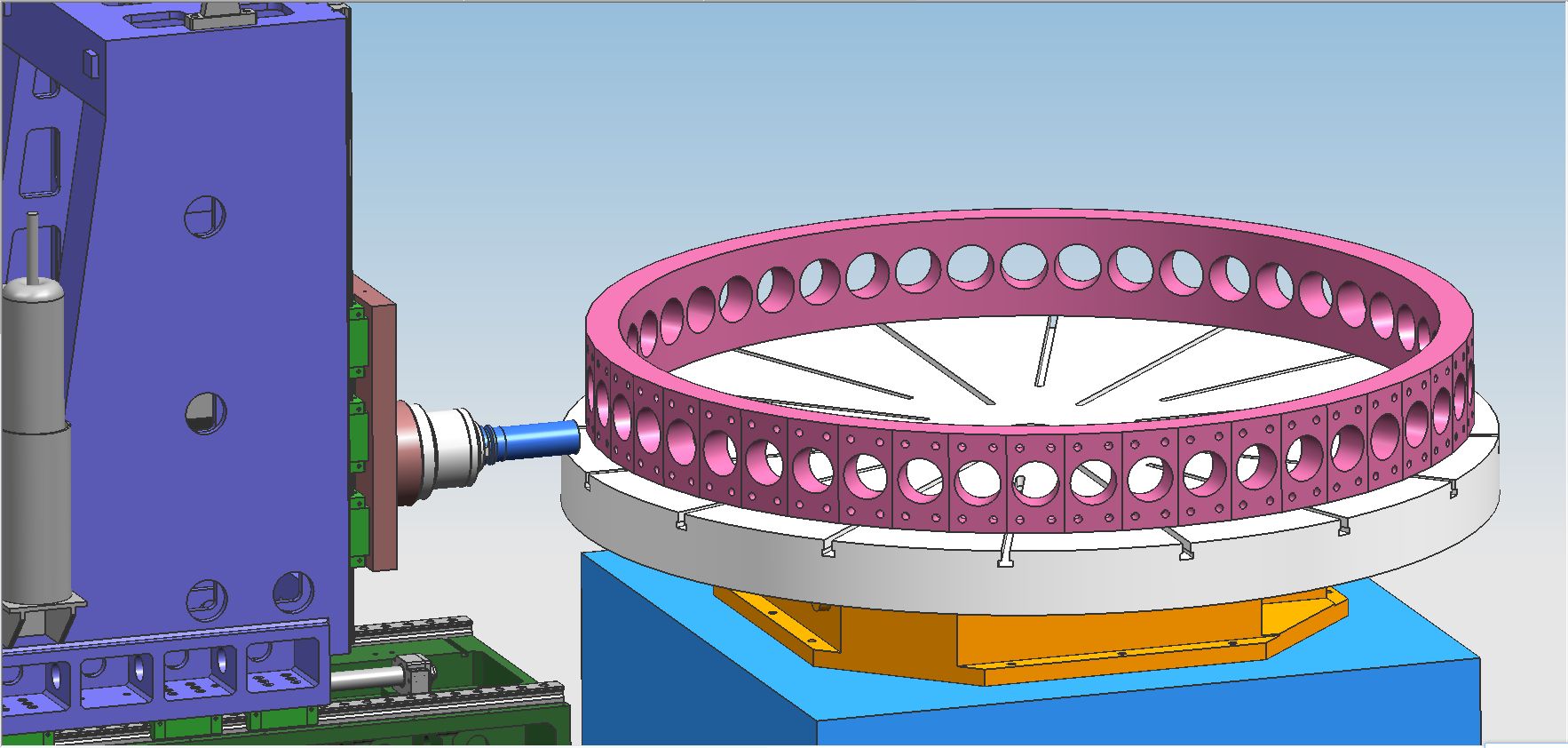

2.4. Isi ike ịkwọ ụgbọ ala: isi ike na-egwupụta ihe na-eji mkpịsị aka Taiwan arụ ọrụ, na spindle nkenke pụrụ iche na-anakọta kọntaktị angular, nke na-achọpụta mgbanwe ọsọ na-enweghị stepless site na nnyefe eriri synchronous siri ike. Ndị moto servo na skru bọọlụ na-anya ya. Enwere ike ijikọ axis Y, na-anata njikwa aka-emechi emechi, ma nwee ike ghọta ọrụ interpolation linear na okirikiri. Ọgwụgwụ spindle bụ oghere taper BT50.

2.5. Ngwa mmanu akpaaka na ngwaọrụ nchebe:

Ejiri igwe a na-eji ngwa mmanu akpaka, nke nwere ike mmanye ụzọ abụọ na-akpụ akpụ dị ka ụgbọ okporo ígwè, skru edu, na racks. Igwe

Z-axis na Y-axis nwere ihe mkpuchi mkpuchi uzuzu, na-etinyekwa baffles na-ekpuchi mmiri na gburugburu tebụl ọrụ.

2.6. Sistemụ njikwa ọnụọgụ dijitalụ zuru oke:

2.6.1. Site n'iji arụ ọrụ mgbawa mgbawa, oge nkwụsị mgbawa na mgbawa mgbawa nwere ike ịtọ na interface nke igwe.

2.6.2. N'iji ngwá ọrụ na-ebuli ngwá ọrụ, ngwá ọrụ na-ebuli elu nwere ike ịtọ na interface nke igwe. Mgbe mkpọpu ihe ruru elu a, a na-ebuli ngwa ngwa a na-ebuli elu n'elu ọrụ ahụ, mgbe ahụ, a na-atụfu ibe ndị ahụ, ma na-ebugharị ngwa ngwa n'elu ebe a na-egwupụta ihe na-akpaghị aka na-arụ ọrụ.

2.6.3. Igbe njikwa ọrụ Centralized na nkeji aka na-enweta usoro njikwa ọnụọgụ ma kwadebere ya na interface USB na ihuenyo ngosipụta kristal mmiri mmiri LCD. Iji kwado mmemme, nchekwa, ngosi na nkwurịta okwu, interface ọrụ nwere ọrụ dị ka mkparịta ụka nke igwe mmadụ, nkwụghachi ụgwọ njehie, na mkpu na-akpaghị aka.

2.6.4. Ngwá ọrụ ahụ nwere ọrụ nke ịhụchalụ na nyochaghachi ọnọdụ oghere tupu nhazi ya, ọrụ ahụ dịkwa mma

* Iji hụ na ịdị mma nke ịkwanye ma na-enye nnukwu mgbanaka nri, igwe anaghị enwe nchebe mpụga, na nchebe mpụga bụ nhọrọ.

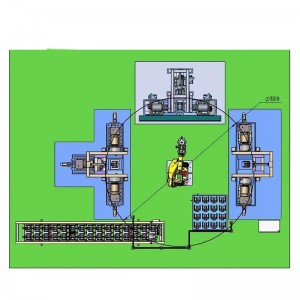

3. Igwejiri gburugburu ebe obibi:

Ike ọkọnọ: Atọ-adọ AC380V±10%, 50Hz±1 Ambient okpomọkụ: 0°~ 45°

4.Usoro nka

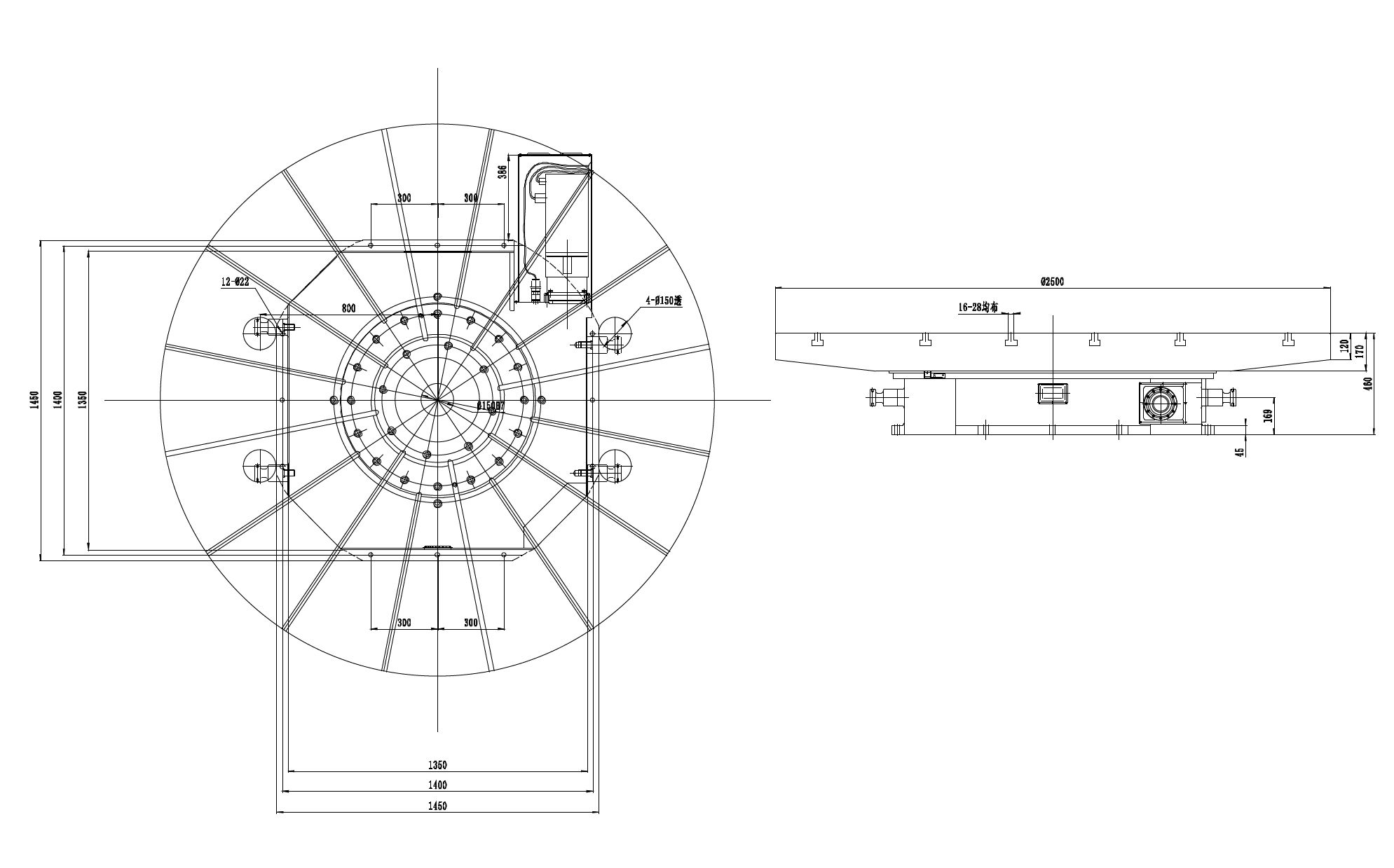

| Nlereanya | BOSM-1000 | |

| Nhazi kacha workpiece size | Dayameta ngbanwe kacha mma nke workpiece (mm) | ≤Φ2000 |

|

Tebụl arụ ọrụ | Akụkụ nke worktable (mm) square | □ 1000 |

| Akụkụ nke worktable (mm) gburugburu | Φ1200 | |

| Ibu oke kwụ ọtọ (kg) | 5000 | |

|

Ngalaba igwu mmiri Ram kwụ ọtọ | ego) | 1 |

| Spindle taper | BT50 | |

| Dayameta mkpọpu mmiri (mm) | 2-120 | |

| Dayameta diski igwe igwe igwe (mm) | 200 | |

| Dayameta ịpị (mm) | M6-M36 | |

| Anya site na nsọtụ spindle ihu ruo etiti tebụl (mm) | 1000-1600 | |

| Ebe dị anya site na etiti spindle ruo n'elu ụgbọ elu nke tebụl (mm) | 100-1100 | |

| Ọsọ spindle (r/min) | 30-3000 | |

| Ike moto (kw) | 30 | |

| Mpempe ọrụ axis rotation (A axis) | Nọmba nkewa kacha (mm) | 360° |

| Tọọ nkeji nkewa kacha nta | 0.001° | |

| A-axis servo moto ike (kw) | 4.2 | |

| Isi ike na-aga aka ekpe na aka nri (X axis) | Kachasị strok (mm) | 2000 |

| Ọsọ-axis X-axis (m/min) | 0 ~ 8 | |

| X-axis servo moto ike (kw) | 2.4 | |

| Isi ike na-akpali elu na ala (Y axis) | Kachasị strok (mm) | 1000 |

| Y-axis na-agba ọsọ ọsọ (m/min) | 0 ~ 8 | |

| Y-axis servo moto ike (kw) | 2.4 breeki | |

| Ogidi ogologo ije (Z axis) | Kachasị strok (mm) | 600 |

| Ọsọ-axis Z-axis (m/min) | 0 ~ 4 | |

| Ike moto Z axis servo (kw) | 2.4 | |

| Ịtọpụta izi ezi | 1000mm | ±0.05 |

| Nkwagharị ugboro ugboro | 1000mm | ±0.025 |

| CNC indexing table indexing ziri ezi (mm) |

| 15” |

| Akụkụ igwe (gụnyere nchekwa) | Ogologo (X) × obosara (Z) × Elu (Y) (mm) | 5300*6000*3400 |

| Nnukwu ibu (t) gụnyere nchekwa | (ihe dị ka) 20 | |