Lathe Drive Center Maka Axle

Nyocha teknụzụ axle ụgbọ ala

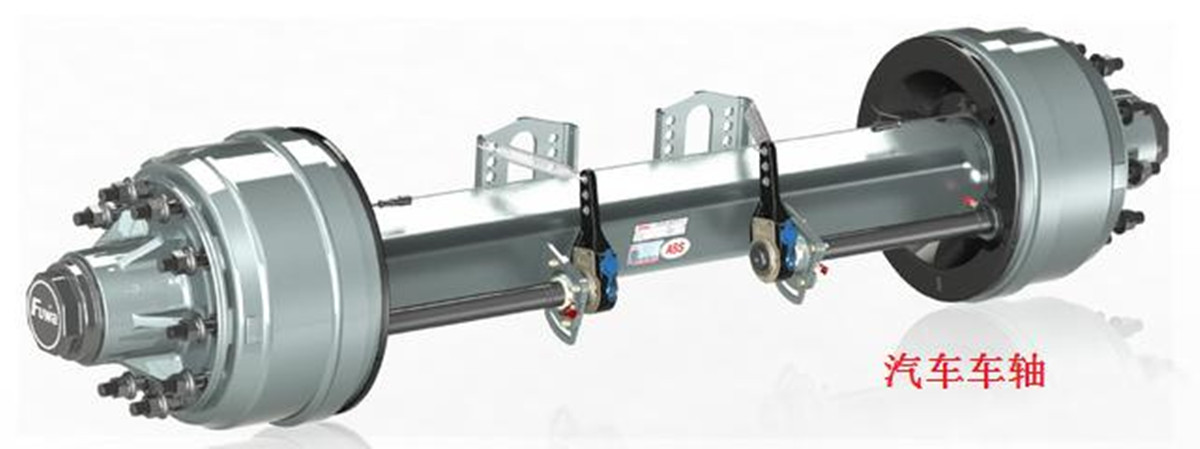

Ụgbọ ala axle

A na-akpọkarị axles nwere wiil n'akụkụ abụọ nke ụgbọ ala (frame) dị ka axles ụgbọ ala, a na-akpọkwa axles nwere ikike ịnya ụgbọ ala. Isi ihe dị iche n'etiti ha abụọ bụ ma enwere mbanye n'etiti axle (axle). N'ime akwụkwọ a, a na-akpọ axle ụgbọ ala nwere unit mbanye ụgbọ ala axle, na ụgbọ ala na-enweghị mbanye a na-akpọ axle ụgbọala iji gosi ihe dị iche.

Site na mmụba na-arịwanye elu maka ngwa ngwa na njem, ịdị elu nke axles ụgbọ ala, ọkachasị ndị na-adọkpụ ụgbọala na ndị na-adọkpụ ụgbọ ala, na njem ndị ọkachamara na ọrụ pụrụ iche na-apụtawanye ìhè, na ahịa ahịa abawanyela nke ukwuu.

Teknụzụ a na-enyocha usoro nhazi nke axle, na-atụ anya inyere ndị ahịa aka ịhọrọ igwe CNC dabara adaba.

Nkewa axle ụgbọ ala:

Ụdị axles dị iche iche dịka ụdị breeki si dị, a na-ekewakwa ya na: diski breeki axles, drum brake axles, wdg.

Dị ka nha nke oghere dayameta nke ogwe osisi, a na-ekewa ya na: American axle, German axle; wdg.

Dị ka ọdịdị na nhazi ya si dị, a na-ekewa ya na:

dum: siri ike square tube axle, oghere square tube axle, oghere okirikiri axle;

gbawara agbawa: aro isi + oghere aro tube ịgbado ọkụ.

Site na ọdịnaya nhazi nke axle, axles siri ike na oghere na-ejikọta na nhọrọ nke ngwa nhazi.

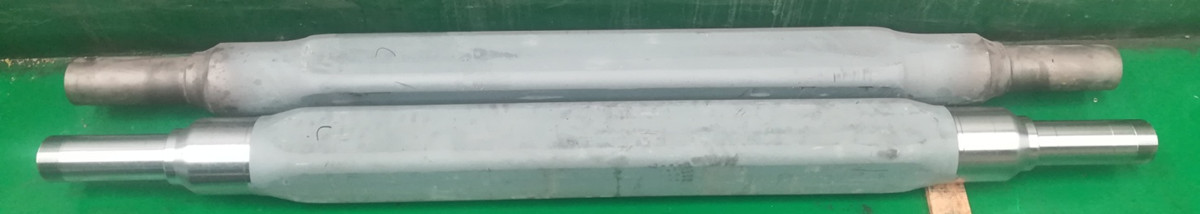

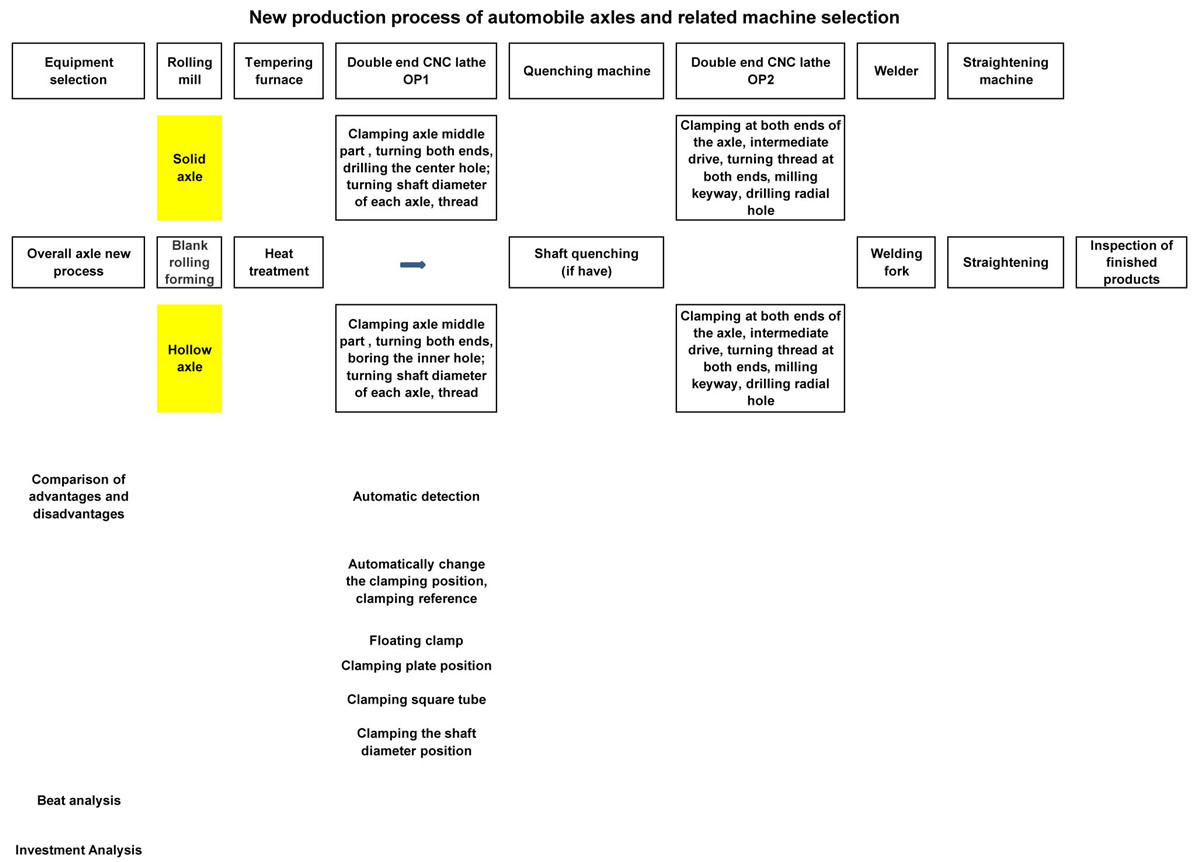

Ndị na-esonụ bụ nyocha nke mmepụta usoro nke dum axle (na-ekewa n'ime siri ike na oghere; square tube na gburugburu tube), na kewaa axle (esi ike na oghere aro isi + oghere aro tube ịgbado ọkụ), akpan akpan, machining usoro. A na-enyocha ya ka ịhọrọ igwe kachasị mma nke ọma.

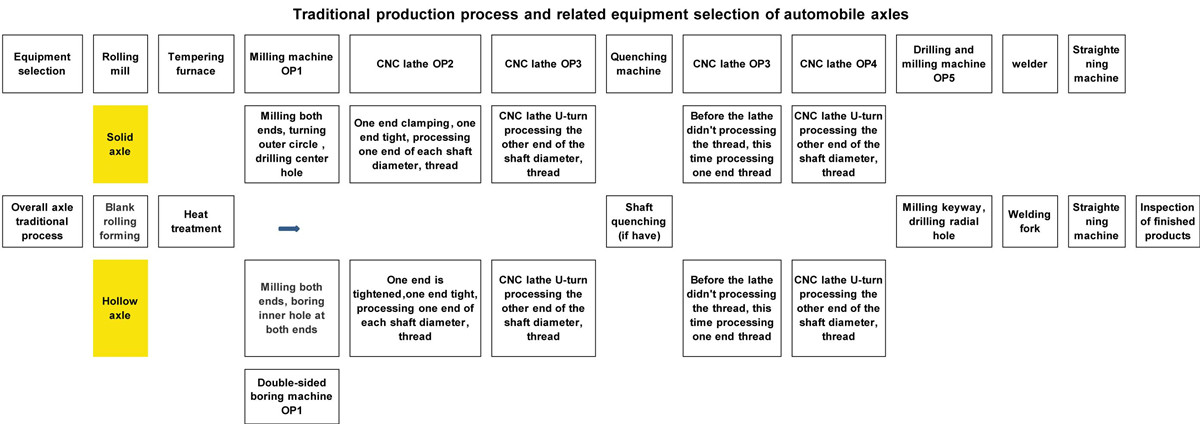

Usoro mmepụta na igwe maka axles ụgbọ ala:

1. Usoro mmepụta omenala nke mkpokọta axle:

Site na usoro mmepụta axle dị n'elu, ọ dịkarịa ala ụdị igwe atọ dị mkpa iji wuchaa machining: igwe na-egwe ọka ma ọ bụ igwe na-agwụ ike nke nwere akụkụ abụọ, CNC lathe, mkpọ ala na igwe igwe, na CNC lathe kwesịrị ịtụgharị (ụfọdụ ndị ahịa nwere. ahọrọla isi abụọ CNC lathe). Banyere nhazi eri, ma ọ bụrụ na a na-emenyụ dayameta osisi ahụ, a na-edozi ya mgbe ọ kwụsịrị; ọ bụrụ na enweghị quenching, a na-edozi ya na OP2 na OP3, na-ahapụkwa ngwaọrụ OP4 na OP5 usoro igwe.

Site na usoro mmepụta ọhụrụ, igwe igwe igwe eji eme ihe (axle siri ike) ma ọ bụ igwe na-agwụ ike nwere akụkụ abụọ (oghere axle) gbakwunyere CNC lathe, omenala OP1 egwe ọka, OP2, OP3 na-atụgharị usoro, na ọbụna OP5 ịkụ ala na-egwe ọka Ọ nwere ike dochie ya. site na njedebe abụọ CNC lathe OP1.

Maka axles siri ike ebe dayameta osisi anaghị achọ imenyụ, enwere ike ịmecha ihe niile dị n'ime igwe n'otu nhazi, gụnyere oghere igodo igwe na-egwupụta oghere radial. Maka oghere oghere ebe dayameta ogwe anaghị achọ imenyụ, enwere ike nweta ọkọlọtọ ngbanwe akpaka na ngwa igwe, yana ọdịnaya igwe nwere ike mechaa ya site na otu ngwa igwe.

Họrọ axle pụrụ iche CNC lathes nwere ngwụcha abụọ ka igwe axles na-eme ka ụzọ igwe dị mkpụmkpụ nke ukwuu, a ga-ebelatakwa ụdị na ọnụọgụ ngwaọrụ igwe ahọpụtara.

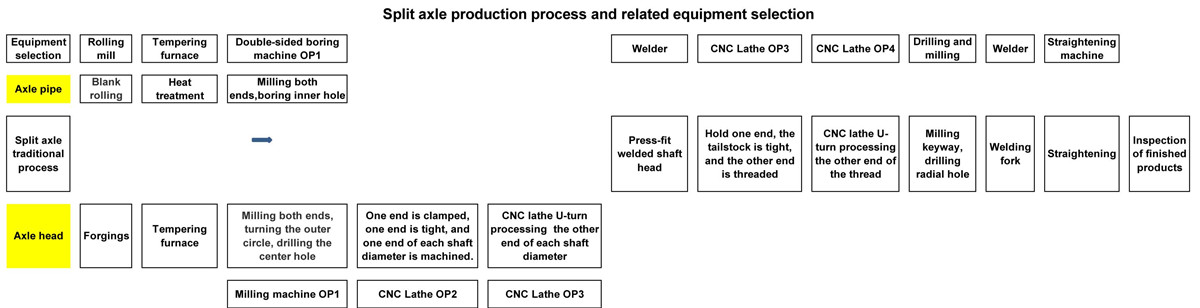

3.Split axle mmepụta usoro:

Site na usoro a dị n'elu, a pụkwara ịhọrọ ngwá ọrụ nhazi nke tube axle tupu ịgbado ọkụ dị ka okpukpu abụọ CNC lathe. Maka nhazi nke axle mgbe ịgbado ọkụ, ihe CNC pụrụ iche maka axles abụọ nwere njedebe kwesịrị ịbụ nhọrọ mbụ: nhazi oge n'otu oge na nsọtụ abụọ ahụ, nhazi nhazi dị elu na nhazi nhazi dị mma. Ọ bụrụ na ụzọ igodo na oghere radial dị na nsọtụ abụọ nke axle chọrọ ka a rụnye igwe ahụ, igwe ahụ nwekwara ike ịnwe njide akụrụngwa iji hazie igodo ụzọ na oghere radial ọnụ.

4.The uru na atụmatụ nke ọhụrụ usoro nhọrọ igwe:

1) itinye uche nke usoro ahụ, na-ebelata oge nke clamping workpiece, na-ebelata oge nhazi inyeaka, na-eji teknụzụ nhazi n'otu oge na nsọtụ abụọ ahụ, a na-eme ka nrụpụta ọrụ dịkwuo mma.

2) Mkpọchi otu oge, nhazi oge n'otu oge na nsọtụ abụọ ahụ na-eme ka nhazi machining na coaxial nke axle dịkwuo mma.

3) Mbelata usoro mmepụta ihe, belata ntụgharị nke akụkụ na saịtị mmepụta, melite arụmọrụ nke saịtị ahụ, ma nyere aka melite nhazi na njikwa nke mmepụta.

4) N'ihi iji ngwá ọrụ nhazi dị elu dị elu, ọ nwere ike ịkwado ya na ntinye na nbudata ngwaọrụ na ngwaọrụ nchekwa iji nweta mmepụta ngwa ngwa zuru oke ma belata ụgwọ ọrụ.

5) A na-ejigide ihe na-arụ ọrụ na etiti etiti, nkedo ahụ bụ nke a pụrụ ịdabere na ya, na torque chọrọ maka igbutu ngwá ọrụ igwe zuru ezu, a pụkwara ịrụ nnukwu ntụgharị.

6) Ngwá ọrụ igwe nwere ike iji ngwaọrụ nchọpụta akpaaka, karịsịa maka oghere oghere, nke nwere ike hụ na nha nha nke axle mgbe emechara.

7) Maka oghere oghere, mgbe oghere dị n'ime na nsọtụ abụọ nke OP1 sequencer gwụchara, ndị ahịa ọdịnala ga-eji otu njedebe welie mwekota na njedebe nke ọzọ na-eji ọdụ ọdụ na-agbatị workpiece maka ntụgharị, mana nha. oghere dị n'ime dị iche. Maka obere oghere dị n'ime, ike siri ike ezughị oke, oke ike nke elu ezughị oke, enweghị ike ịmecha ịkpụcha nke ọma.

Maka lathe ọhụrụ ihu abụọ, oghere oghere, mgbe oghere dị n'ime na nsọtụ abụọ nke ụgbọ ahụ gwụchara, igwe ahụ na-agbanwe ọnọdụ clamping na-akpaghị aka: a na-eji nsọtụ abụọ ahụ sie ike na-arụ ọrụ, na draịva etiti na-ese n'elu workpiece. na-ebunye torque.

8) The headstock na arụnyere hydraulic clamping workpiece nwere ike ịkwaga na Z ntụziaka nke igwe. Onye ahịa nwere ike ijide ọnọdụ ahụ n'etiti tube nke etiti (tube gburugburu), ọnọdụ efere ala na oghere oghere nke axle dị ka ọ dị mkpa.

5. Nkwubi okwu:

N'ihi ọnọdụ dị n'elu, iji CNC lathes nwere njedebe abụọ na axles ụgbọ ala nwere nnukwu uru karịa usoro omenala. Ọ bụ nkà na ụzụ mmepụta ihe dị elu nke nwere ike dochie ngwá ọrụ igwe omenala na usoro mmepụta ihe na nhazi igwe.

Akụkụ etiti nke

6.Axle ahịa ahịa

Okwu mmalite Axle CNC nwere ngwụcha okpukpu abụọ pụrụ iche

Usoro nhazi axle: ∮50-200mm, □50-150mm, ogologo nhazi: 1000-2800mm

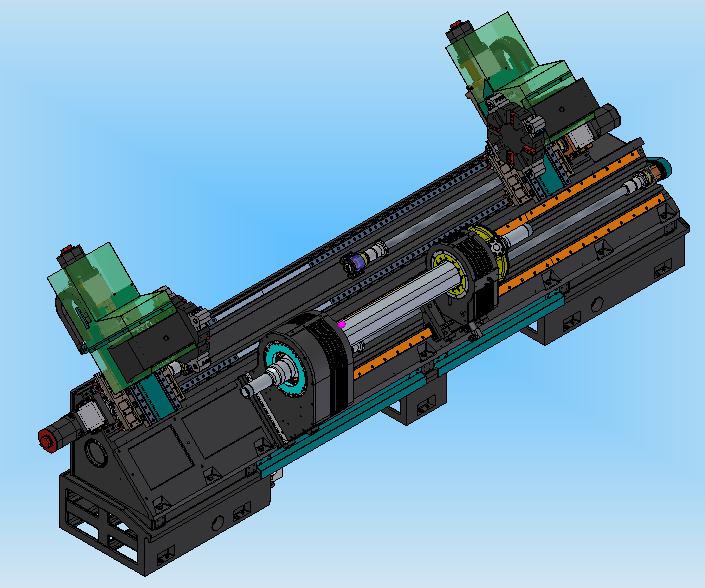

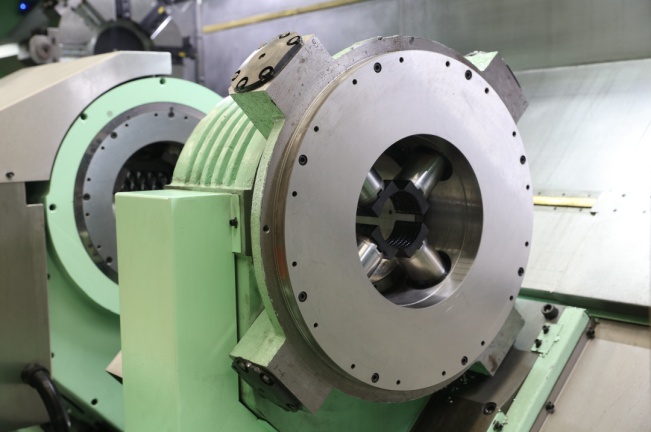

Ọdịdị igwe na mmeghe arụmọrụ

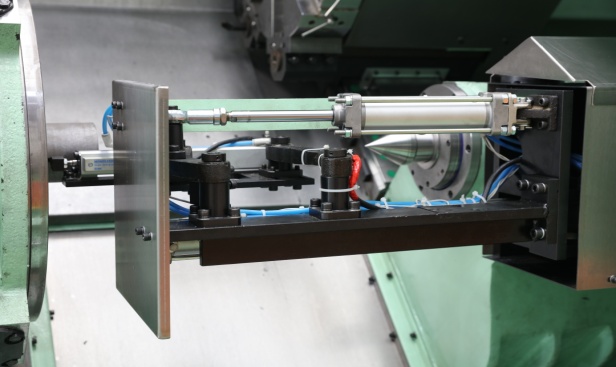

Ngwá ọrụ igwe na-anabata nhazi akwa akwa 45 Celsius, nke nwere ezigbo nkwụsi ike na mgbapụ mgbawa dị mfe. The headstock na intermediate mbanye clamping ọrụ na-ahaziri n'etiti bed, na abụọ ngwá ọrụ ejiri na-ahaziri n'akụkụ abụọ nke spindle igbe. Opekempe clamping ogologo nke igwe bụ 1200mm na kacha machining ogologo bụ 2800mm. A na-anabata ntuziaka na-atụgharị, na onye ọ bụla servo feed shaft na-anakwere screw ball ogbi dị elu, na njikọ na-agbanwe agbanwe na-ejikọta ya kpọmkwem, ụda ahụ dịkwa ala, nhazi nhazi na nhazi nhazi ugboro ugboro dị elu.

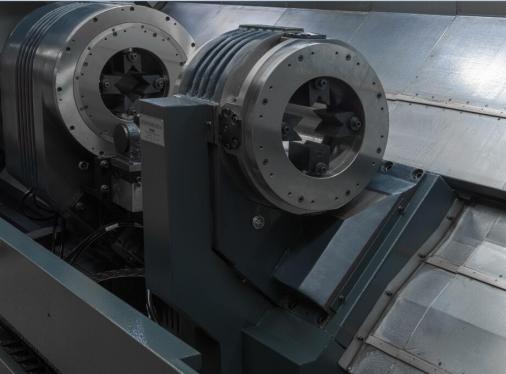

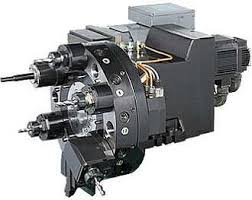

■A na-eji igwe na-ahụ maka njikwa ọwa abụọ kwadoro igwe ahụ. Enwere ike ijikọ ndị na-ejide ngwá ọrụ abụọ ahụ na spindle n'otu oge ma ọ bụ iche iche iji mechaa n'otu oge ma ọ bụ usoro nhazi nke njedebe abụọ nke akụkụ ahụ.

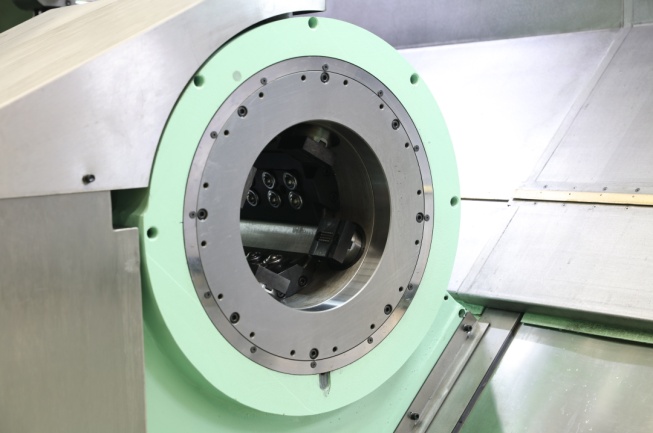

■A na-eji igwe eji akwa isi abụọ rụọ igwe. A na-edozi isi ụlọ isi n'etiti ihe ndina, na moto servo na-enye ike na isi ihe site na eriri ezé. The sub-spindle igbe arụnyere na ala ndu ụgbọ okporo ígwè nke igwe ngwá ọrụ, coaxial na isi spindle igbe, na ike axially site servo moto nwere ike ịkwaga axially site na servo moto ikwado loading na nbudata nke akụkụ, na ọ na-adaba adaba iji dozie dị iche iche clamping. ọnọdụ. Mgbe a na-arụ ọrụ akụkụ, a na-akpọchi ntọala sub-spindle na ụgbọ okporo ígwè igwe. A na-ekwe nkwa izi ezi nke coaxial nke isi isi abụọ site na usoro mmepụta ihe, na-eme ka ọkwa dị elu nke concentricity nke akụkụ igwe.

■The Headstock na-ejikọta usoro spindle, nhazi na usoro nkesa mmanụ, ma nwee nhazi kọmpat na ọrụ a pụrụ ịdabere na ya. The kpọmkwem clamping dayameta na obosara nke headstock na-ekpebisi ike site axle nke ndị ahịa akụkụ.

A na-eji ụzọ abụọ nke eriri na ngwa na-eji nwayọọ nwayọọ na-akụ isi ụlọ ahịa, na-eme ka spindle nwee ike iwepụta nnukwu iyi. A na-etinye ihe nkedo n'akụkụ aka ekpe nke isi isi na njedebe aka nri nke sub-headstock iji ghọta njide nke akụkụ ahụ. Mgbe nnukwu akpa isi na-ebugharị akụkụ ahụ ka ọ tụgharịa, akụkụ sub-headstock clamping clamping na-eji isi isi na-atụgharị.

A na-etinye ihe nrụnye ahụ na cylinders radial atọ (4 radial cylinders ma ọ bụrụ na ma ihe gburugburu na ihe square ahụ na-ejikọta), a na-emegharị piston site na nrụgide hydraulic, na-etinyekwa claws na njedebe nke piston iji ghọta onwe ya. centering nke akụkụ. Ịkụgide. Ọ dị ngwa ma dị mfe ịgbanwe claws mgbe ị na-agbanwe akụkụ. A na-edozi ike nkedo site na usoro hydraulic hydraulic pressure. Mgbe a na-emepụta akụkụ ahụ, ihe nkedo ahụ na-atụgharị na isi isi, na usoro nkesa mmanụ na-enye mmanụ na-agbanye mmanụ, nke mere na ihe nkedo ahụ nwere ike ijide ike zuru ezu n'oge ntụgharị. Mwekota nwere uru nke nnukwu njigide ike na nnukwu strok.

∎ Iji dozie nsogbu nke nha mgbidi edo mgbe igwe oghere axle nke onye ahịa gasịrị, enwere ike iji ngwaọrụ nyocha akpaka workpiece. Mgbe emechara axle clamping, workpiece na-achọpụta na-akpaghị aka na nyocha na-agbatị ma tụọ ọnọdụ nke workpiece; mgbe emechara nha ahụ, ngwaọrụ ahụ na-atụgharị n'ime oghere mechiri emechi.

N'ihi na dị iche iche machining usoro nke oghere axles, ma ọ bụrụ na ibu ọnọdụ na-eji dị ka clamping ntụaka, igwe Ọdịdị na akpaka clamping na clamping nwere ike họrọ, na programmable ọdụ ọdụ na-nyere na abụọ nke isi na inyeaka spindle isi izute ndị isi. chọrọ nke otu igwe. A na-atụ anya na ọ ga-emecha nhazi nke nzọụkwụ abụọ n'otu oge. N'otu oge ahụ, ọ na-emekwa ka akụkụ nke nbudata na nbudata na-akpaghị aka nwere ọtụtụ nhọrọ dị mma.

∎ Enwere ike ijikwa ngwa ọrụ rotary nkịtị ma ọ bụ turrets ndị na-ejide ngwá ọrụ aka ekpe na aka nri. Ha nwere ọrụ mkpọpu na igwe nri, nke nwere ike mechaa mkpọpu na-egwe ọka nke akụkụ ndị dị mkpa.

∎ Ngwa igwe a na-ekpuchi ya nke ọma ma nwee ngwaọrụ mmanye akpaka na ngwaọrụ mwepụ akpaaka (n'ihu). Ọ nwere ọrụ nchebe dị mma, ọdịdị mara mma, ọrụ dị mfe na nhazi dị mma.

■ A na-ekpebi nkọwa zuru ezu nke igwe na nhazi dịka ihe achọrọ axle na ihe ndị ahịa chọrọ, na agaghị eme ya ọzọ ebe a.

Daalụ maka nlebara anya gị!