Ụdị Gantry CNC Drilling na igwe-egwe ọka

CNC Gantry Milling na Drilling Machine

Gantry Drilling na igwe igwe igwe

Igwe eji igwe igwe CNC Gantry

Ngwa igwe

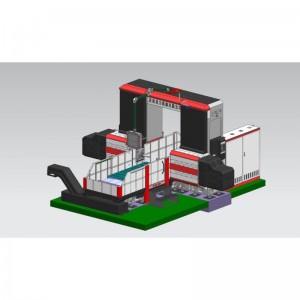

BOSM gantry mobile CNC ngwa-ngwa-ngwa-ngwa-ngwa na igwe igwe usoro na-eji eme ihe maka nrụpụta ọrụ dị elu na nhazi nke nnukwu efere, flanges ike ikuku, diski, akụkụ mgbanaka na ihe ndị ọzọ na-arụ ọrụ na ọkpụrụkpụ n'ime oke dị irè. Enwere ike ịme ihe site na oghere na oghere kpuru n'otu akụkụ ihe onwunwe na ihe ndị mejupụtara. A na-achịkwa usoro nhazi nke igwe eji eme ihe, na ọrụ ahụ dị nnọọ mma. Ọ nwere ike na-aghọta akpaaka, elu nkenke, multiple iche na uka mmepụta. Iji gboo mkpa nhazi nke ndị ọrụ dị iche iche, ụlọ ọrụ ahụ emepụtala ngwaahịa dị iche iche emechara. Na mgbakwunye na ụdị ndị a na-ahụkarị, enwere ike ịhazi na hazie ha dịka mkpa ndị ọrụ siri dị.

Ọdịdị igwe

Nke a na ngwá tumadi mejupụtara bed worktable, ibughari gantry, ibughari sliding sadulu, mkpọpu ala na-egwe ọka ike isi, akpaka lubrication ngwaọrụ na nchedo ngwaọrụ, ikesa jụrụ ngwaọrụ, dijitalụ akara usoro, eletriki usoro, wdg Rolling ndu okporo ígwè ụzọ nkwado na nduzi, nkenke ziri ezi. ndu ịghasa ụzọ mbanye, igwe ngwá ọrụ nwere elu n'ọnọdu ziri ezi na ikwugharị n'ọnọdu ziri ezi.

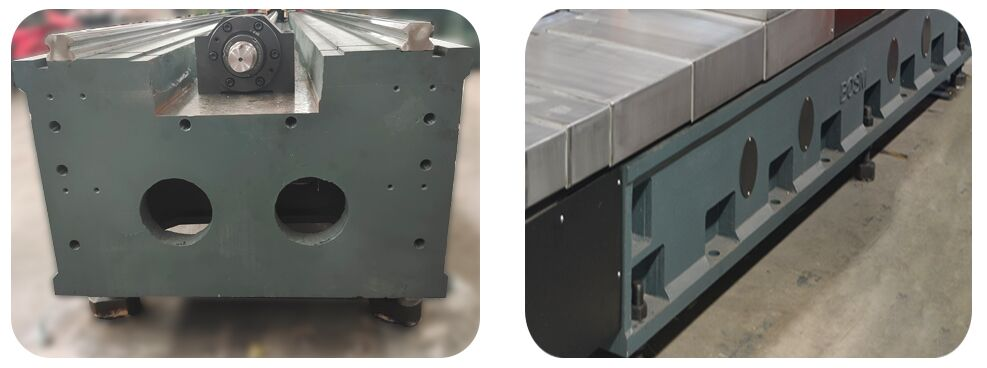

1)Tebụl arụ ọrụ:

Ihe ndina ahụ bụ ihe nkedo nwere otu akụkụ, emechara ka emechara nke abụọ na ọgwụgwọ ịka nká nke ọma, na-enwe ezigbo ike siri ike na kwụ ọtọ na enweghị nrụrụ. Enwere oghere T nwere okirikiri imecha ezi uche dị n'elu tebụl na-arụ ọrụ maka ịmachi workpieces. A na-eji akwa akwa akwa akwa 2 ntuziaka linear dị elu (4 n'akụkụ abụọ n'ozuzu ya), nke mere na a na-emesi ihe mmịfe ntuziaka ahụ ike nke ukwuu, nke na-eme ka ihe siri ike nke igwe na-arụ ọrụ nke ọma na nkwụsi ike na nkwụsịtụ ya. Sistemụ draịva ahụ na-anabata moto AC servo na nkenke bọọlụ ịghasa ụzọ abụọ. N'akụkụ mbanye na-eme ka gantry na-aga na ntụziaka X-axis. A na-ekesa bolts na-agbanwe agbanwe na ala ala nke ihe ndina, nke nwere ike ịhazigharị ọkwa nke ihe ndina ahụ n'ụzọ dị mfe.

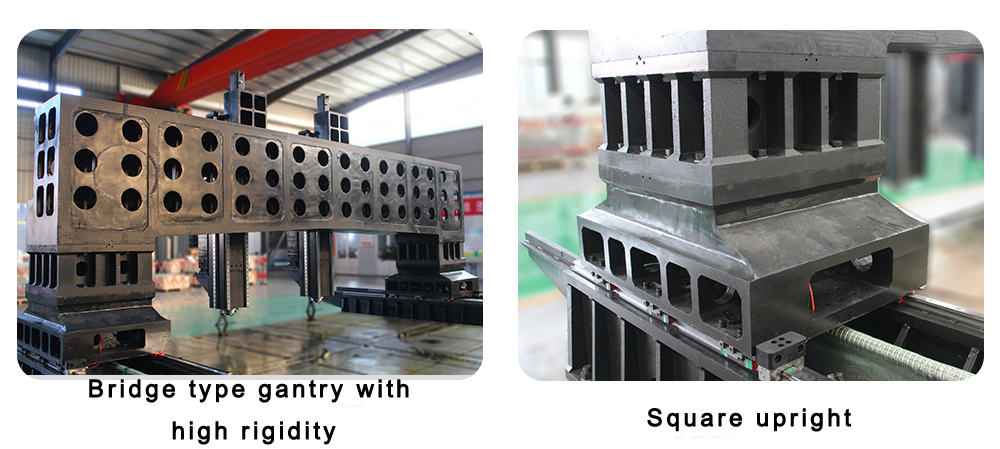

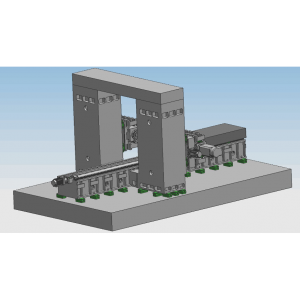

2)Movinggantry:

A na-eji ígwè isi awọ (HT250) mee ihe nkedo ma na-edozi ya. Abụọ 55# ultra-high bearing power rolling linear ndu ụzọ abụọ na-arụnyere n'ihu akụkụ nke gantry. Otu setịpụrụ nkenke bọọlụ ziri ezi na moto servo na-eme ka isi ike na-amali ka ọ gaa na ntụzịaka Y-axis, a na-etinyekwa isi ike mkpọpu na slide isi ike. A na-enweta mmegharị nke gantry site na ntụgharị nke bọọlụ ịghasa nut na ịghasa bọọlụ nke servo moto na-ebugharị site na njikọ ziri ezi.

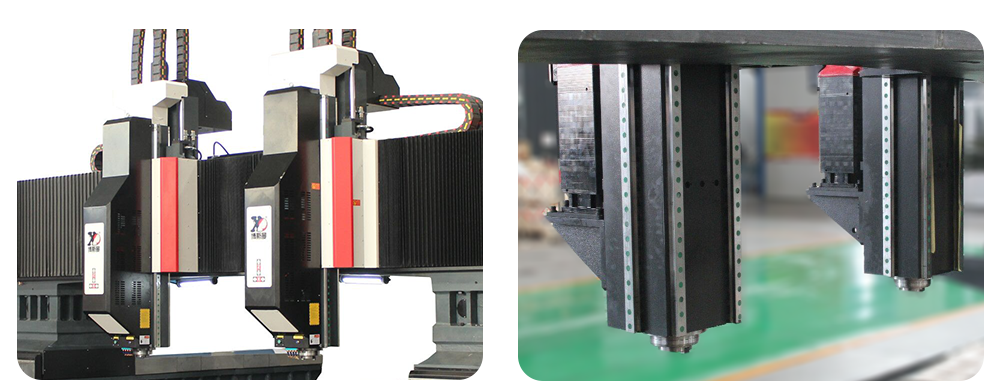

3)Movingsadulu na-amị amị:

Saddle na-amị amị bụ nhazi nke nkedo nke ọma. A na-eji ihe mkpuchi ụgbọ okporo ígwè CNC abụọ dị elu na-ebu ibu, otu ụzọ mgbanaka bọọlụ ziri ezi na ihe na-ebelata mbara ala dị elu jikọtara na moto servo, ma nwee nitrogen Balance cylinder, dozie ịdị arọ nke ahụ. isi ike, belata ibu nke ịghasa ndu, gbatịa ndụ nke ịghasa ndu, chụpụ isi ike nke ịgbapu ka ọ gaa na ntụzịaka Z-axis, wee ghọta ngwa ngwa na-aga n'ihu, rụọ ọrụ n'ihu, tụgharịa ngwa ngwa, ma kwụsị omume nke isi ike, nwere mgbawa mgbawa akpaka, iwepụ mgbawa, ọrụ kwụsịtụ.

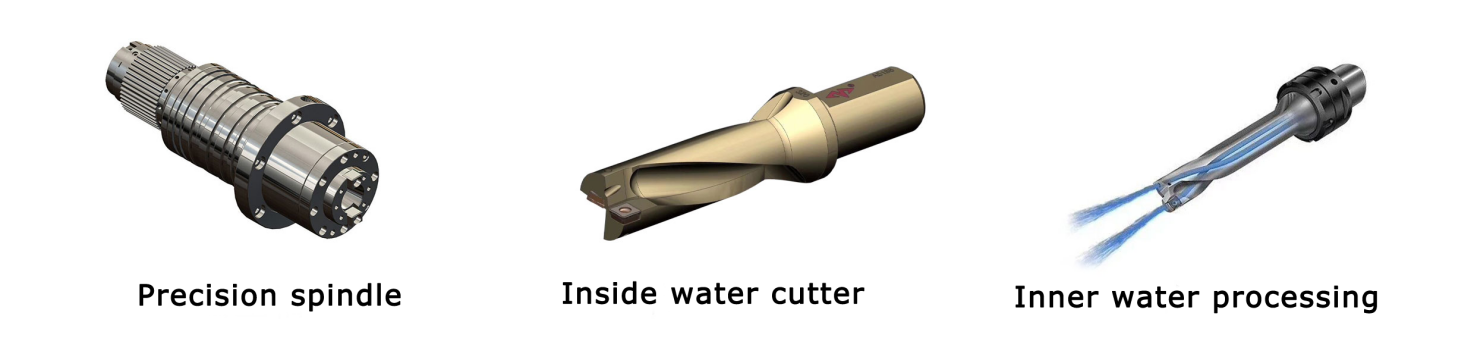

4)Isi ike igwu mmiri(Spindle):

Isi ike mkpọpu na-eji moto servo spindle raara onwe ya nye, bụ nke a na-eji mgbada belt synchronous nha nha na-akwali iji mụbaa torque ma na-ebunye eriri ziri ezi raara onwe ya nye. Mkpanaka ahụ na-ewere ahịrị anọ nke mbụ na azụ abụọ ahịrị isii nke ahịrị kọntaktị akụkụ Japan iji nweta mgbanwe ọsọ na-enweghị nzọụkwụ. A na-eji spindle nwere usoro mgbanwe ngwá ọrụ pneumatic iji mee ka ngwá ọrụ ahụ dị ngwa ngwa ma dị mfe, na nri na-ebugharị site na servo moto na bọmbụ bọl. Enwere ike ijikọ axes X na Y, na-eji njikwa loop mechiri emechi, nke nwere ike ghọta ọrụ interpolation linear na okirikiri. Ngwunye spindle bụ oghere taper BT50, nke nwere nkwonkwo Rotofors Italiantali na-agba ọsọ dị elu, nke enwere ike ịhazi ya site na nnukwu U-drilling center.

4.1 A na-eme igbe ahụ na tebụl na-amị amị nke isi ike na-egwupụta ihe nkedo iji mee ka ha sie ike na nkwụsi ike ha, ma belata mkpọtụ na mkpọtụ.

4.2 Enwere ike iji igwe igwe eletrik rụọ ọrụ igwe; iji chekwaa oge ma melite arụmọrụ mmepụta n'oge nhazi, mgbe ị gbasasịrị oghere mbụ iji tọọ ọnọdụ nri, ịkụnye oghere ndị fọdụrụ nke otu ụdị ahụ nwere ike ime ngwa ngwa → ọrụ ọganihu → ngwa ngwa na-atụgharị Ọ kwesịkwara inwe ọrụ dịka mgbawa akpaka. imebi, iwepụ mgbawa, na kwụsịtụ.

4.3 Ebulu ahụ nwere sistemu itule nitrogen mmiri mmiri iji belata ibu Z-axis wee bulie ndụ ọrụ nke ịghasa axis Z.

4.4 Moto Z-axis servo moto na-anakwere moto breeki na-apụ apụ, nke ga-ejide breeki mgbe ebibiri ike na mberede iji zere ihe mberede kpatara ọdịda nke igbe spindle.

4.5 Isi ihe

4.5.1. Igbe isi igbe na-anakwere ntuziaka ahịrị ahịrị anọ dị arọ, nke nwere nnukwu nkwụsi ike nke ngagharị, nkwụsi ike dị elu, yana ezigbo nkwụsi ike dị ala.

4.5.2. Z-axis mbanye - moto servo na-ejikọta ya na nkedo bọọlụ site na njikọta, na ịghasa bọọlụ na-eme ka isi ihe na-aga elu na ala na sadulu iji ghọta nri axis Z. Moto Z-axis nwere ọrụ breeki akpaka. N'ọnọdụ nke ọdịda ike, a na-ejide eriri moto ahụ nke ọma ka ọ ghara ịgbagharị.

4.5.3. The spindle otu adopts Taiwan Jianchun elu-ọsọ esịtidem mmiri outlet spindle, nke nwere elu nkenke na elu arụmọrụ. Isi aro na-ejide mma site na mmiri nru ububa n'elu ogwe isi ya na ike mgbakasị ahụ na-arụ ọrụ na ntu nke ngwá ọrụ ahụ site na usoro broach akụkụ anọ, na ngwá ọrụ rụrụ arụ na-agbaso usoro pneumatic.

5)Ngwa mmanu akpaaka na ngwaọrụ nchebe:

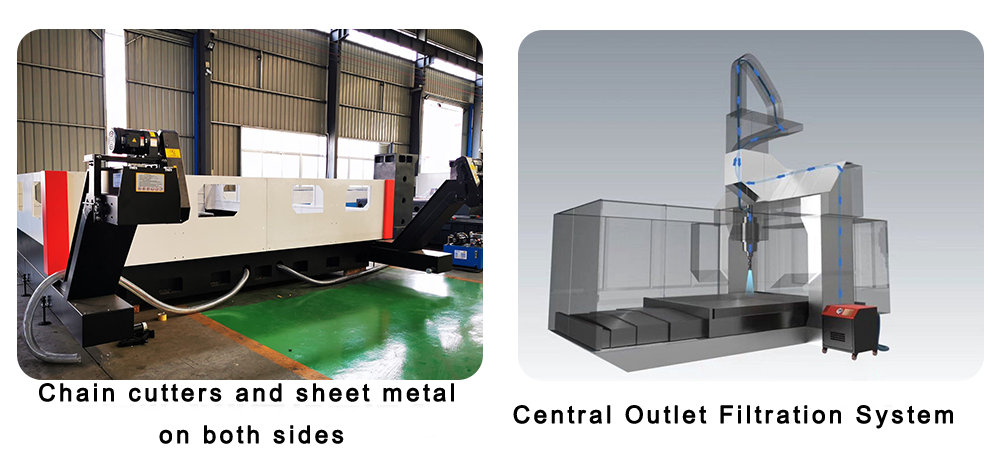

Enwere ihe ebufe mgbawa akpaka n'akụkụ abụọ nke bench yana nzacha na njedebe. Ihe ebufe mgbawa akpaka bụ ụdị yinye dị larịị. Ejiri otu akụkụ nwere mgbapụta jụrụ oyi, a na-ejikọta oghere ahụ na usoro nzacha mmiri nke etiti na eriri. , The coolant eruba n'ime mgbawa ebu, mgbawa ebu ebuli mgbapụta mgbapụta coolant n'ime Central outlet nzacha usoro, na elu-nrụgide jụrụ mgbapụta na-ekesa nzacha coolant na spindle mkpọpu mmiri jụrụ. A na-ejikwa ụgbọ ala mgbawa na-ebufe ya, nke na-adaba adaba n'ibufe ibe. Akụrụngwa a na-eji usoro ihe eji eme ihe dị n'ime na nke mpụga. Mgbe a na-eji mkpọpu ngwa ngwa dị elu, a na-eji ihe dị n'ime ya mee ihe na-eme ka ọ dị jụụ, na-eme ka ọ dị jụụ n'èzí maka igwe igwe ọkụ.

5.1. Sistemụ nzacha mmiri nke etiti:

Ngwá ọrụ igwe a nwere usoro nzacha mmiri dị n'etiti, nke nwere ike nyochaa ihe adịghị ọcha na coolant nke ọma. Usoro ịgba mmiri dị n'ime nwere ike igbochi ntụtụ ígwè ka ọ ghara ịbanye na ngwá ọrụ ahụ n'oge nhazi, belata ngwá ọrụ ngwá ọrụ, gbasaa ndụ ngwá ọrụ, ma melite njedebe elu nke workpiece. The ngwá ọrụ n'ọnụ elu-nrụgide mmiri mwepu pin nwere ike nke ọma na-echebe elu nke workpiece, chebe elu-ọsọ rotary nkwonkwo, gbochie adịghị ọcha igbochi rotary nkwonkwo, na melite àgwà nke workpiece n'ozuzu, na melite ọrụ arụmọrụ.

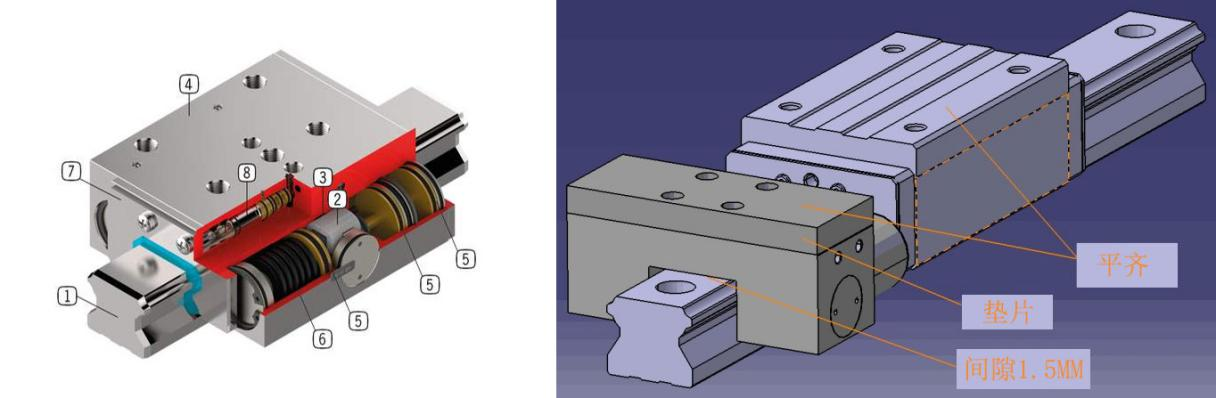

6)Linear Clamper:

Mwekota bụ isi ahụ nke mwekota, actuators, wdg. Ọ bụ a elu-arụmọrụ arụ ọrụ akụrụngwa eji na njikọ na Rolling linear ndu ụzọ. Site na ụkpụrụ nke wedge block Force mgbasawanye, ọ na-emepụta ike clamping ike; o nwere ihe eji arụ ọrụ nke ọma, ọnọdụ ziri ezi, mgbochi ịma jijiji na Ọrụ iji meziwanye isi ike.

O nwere njirimara ndị a:

Nchekwa na ntụkwasị obi, ike njigide siri ike, na-akụda axis XY na-adịghị emegharị n'oge mkpọpu na ịme ọpịpị.

Ike njigide dị oke elu na-abawanye nkwụsi ike nke nri axial ma na-egbochi mkpasu iwe nke ịma jijiji kpatara.

Nzaghachi ngwa ngwa, oge nzaghachi mmeghe na mmechi bụ nanị 0.06 sekọnd, nke nwere ike ichebe ngwá ọrụ igwe ma mee ka ndụ nke ịghasa ndu.

Na-adịgide adịgide, elu nickel-plated, ezigbo ọrụ mgbochi nchara.

Nhazi ọhụrụ iji zere mmetụta siri ike mgbe ị na-agbatị.

7)Ndokwa na ịmachi nke workpiece

N'ihi na gburugburu flange workpiece itinye n'ọnọdụ, ọ nwere ike aka ike tinye na nkwado efere na T-oghere, na etiti ọnọdụ a tụrụ site n'ọnụ finder arụnyere na spindle taper oghere na ihe ọ bụla atọ isi (n'ime dayameta ma ọ bụ mpụta dayameta) na workpiece. . Mgbe nke ahụ gasịrị, a na-enweta ya na-akpaghị aka site na nchịkọta usoro nchịkwa ọnụọgụ, nke ziri ezi na ngwa ngwa. A na-ejikọta ihe nkedo nke workpiece site na mwekota nke nwere efere ịpị, mkpanaka ejector, eriri eriri na ihe mgbochi, nke dị mma iji.

8)Ngwa mmanu akpaaka

Ngwá ọrụ igwe a nwere ngwaọrụ Taiwan nke mbụ volumetric partial pressure akpaka mmanu mmanu, nke nwere ike mmanu na-akpaghị aka dị iche iche ngagharị ụzọ ụzọ ụgbọ okporo ígwè, ndu skru, racks, wdg, na-enweghị nwụrụ anwụ ọgwụgwụ, na hụ na ọrụ nke igwe ngwá ọrụ. Ụgbọ okporo ígwè na-eduzi n'akụkụ abụọ nke akwa igwe na-eji mkpuchi mkpuchi igwe anaghị agba nchara, na akụkụ abụọ nke isi ike gantry na-eji mkpuchi na-agbanwe agbanwe. A na-etinye ihe nchebe mmiri na-ekpuchi mmiri na gburugburu tebụl ọrụ ahụ, a na-echekwa eriri ọkpọ mmiri site na eriri ịdọrọ plastik. A na-etinye ákwà mgbochi PVC dị nro na-enweghị atụ n'akụkụ mkpịsị aka.

9)Ihe njikwa CNC dijitalụ zuru oke:

9.1. Site n'iji arụ ọrụ mgbawa mgbawa, oge mgbawa na mgbawa mgbawa nwere ike ịtọ na interface nke igwe.

9.2. Site na ọrụ ebuli ngwá ọrụ, ngwá ọrụ na-ebuli elu nwere ike ịtọ na interface nke igwe-igwe. Mgbe a na-egwupụta ihe n'ịdị elu a, a na-ebuli ihe ọkụkụ ahụ ngwa ngwa n'elu nke workpiece, na mgbe ahụ shavings, mgbe ahụ ngwa ngwa na-aga n'ihu na mkpọpu elu na-akpaghị aka converted na-arụ ọrụ ndepụta.

9.3. Igbe njikwa ọrụ etiti na ngalaba ejiri aka na-anabata sistemu njikwa ọnụọgụ, ma kwadebere ya na interface USB na ngosipụta kristal mmiri mmiri LCD. Iji kwado mmemme, nchekwa, ngosi na nkwurịta okwu, interface ọrụ nwere ọrụ dị ka mkparịta ụka nke igwe mmadụ, nkwụghachi ụgwọ njehie, na mkpu na-akpaghị aka.

9.4. Ngwá ọrụ ahụ nwere ọrụ nke nlele na nyochaghachi nke oghere oghere tupu nhazi, nke dị nnọọ mma iji rụọ ọrụ.

10)Ihe nchọta ihu anya:

Akụrụngwa na-eji ihe nchọta ihu fotoelectric, nke nwere ike ịchọta ọnọdụ nke workpiece nke ọma na ngwa ngwa.

1) Wụnye ihe nchọta ihu n'ime mkpịsị mkpịsị aka nke akụrụngwa igwe, wee jiri nwayọ tụgharịa mkpịsị ugodi ahụ iji mezie mkpa ya.

2) Bugharịa spindle na handwheel, nke mere na nsọtụ nke n'ọnụ onye na-achọ bọọlụ nchara metụ workpiece gwuo egwu, na-acha uhie uhie ọkụ na-agbanye. N'oge a, spindle nwere ike ibugharị na-aga n'ihu na azụ ugboro ugboro ka ịchọta ebe kacha mma ebe nsọtụ bọọlụ nchara nchara na-emetụ n'ahụ. .

3) Dekọọ ụkpụrụ axis X na Y nke usoro CNC gosipụtara n'oge a, wee dejupụta kọmputa.

4) Chọta ọtụtụ ihe nchọpụta n'ụzọ dị otú a

11)Oti mkpu ngwá ọrụ

Oti mkpu ngwá ọrụ na-achọpụta ihe dị ugbu a nke moto spindle. Mgbe nke ugbu a karịa preset uru, ngwaọrụ na-akpaghị aka na-ekpe ikpe na ngwá ọrụ agwụla, na spindle ga-akpaghị aka weghachi ngwá ọrụ n'oge a, na akpaka omume ga-akwụsị. Chetara onye ọrụ na ngwaọrụ ahụ agwụla.

12)Oti mkpu ọkwa mmiri dị ala

1) Mgbe coolant na nzacha dị n'etiti larịị, usoro na-akpaghị aka jikọọ moto na-amalite, na coolant na mgbawa ebu na-akpaghị aka eruba n'ime iyo. Mgbe ọ ruru ọkwa dị elu, moto na-akwụsị ịrụ ọrụ ozugbo.

2) Mgbe coolant dị na nzacha dị na ọkwa dị ala, sistemụ ahụ ga-eme ka nlele ọkwa na-akpaghị aka, spindle ga-ewepụ ngwa ahụ ozugbo, igwe ga-akwụsị ịrụ ọrụ.

13) Ịgbanyụ ọrụ ebe nchekwa

N'ihi nkwụsị ọrụ kpatara site na mberede ike ọdịda, ọrụ a nwere ike ngwa ngwa na adaba ịchọta ọnọdụ nke oghere ikpeazụ gbapụrụ tupu ọdịda ike. Ndị na-arụ ọrụ nwere ike ịga n'ihu ngwa ngwa na nzọụkwụ ọzọ, na-echekwa oge ọchụchọ.

Nyocha laser atọ axis:

A na-ahazi igwe ọ bụla nke Bosman na interferometer laser nke ụlọ ọrụ Britain RENISHAW, ma na-enyocha nke ọma ma kwụọ ụgwọ njehie pitch, nkwụghachi azụ, nguzozi nke ọma, ikwughachi nkwụsi ike, wdg, iji hụ na ike, kwụsie ike na nhazi nhazi nke igwe. . Nyocha bọọlụ igwe ọ bụla na-eji bọọlụ ụlọ ọrụ RENISHAW nke Britain na-emezigharị ezi okirikiri na izi ezi geometric igwe. N'otu oge ahụ, a na-eme nnwale ịkpụ okirikiri iji hụ na igwe igwe 3D ziri ezi yana izi ezi okirikiri.

okirikiri nhọrọ ukwuu, workpiece clamping, akpaka mgbawa mwepụ chọrọ

1. Main ikpo okwu (1 pcs): T-oghere clamping ọrụ ibe. Ma elu njedebe elu na akụkụ akụkụ nke isi ikpo okwu nwere ike iji mee ihe dị ka nhazi nhazi.

2. Sinking ikpo okwu (1 pcs): (akụkụ na-onwem na inyeaka pịa-dabara etiti, na n'elu na-onwem na zuru-ekpuchi nchebe mkpuchi, e mere na arụnyere site na-ere ákwà), isi workpiece n'ọnọdu na nhazi ntuziaka:

Nhazi mkpuchi Valve: n'ọkwa nke ala ikpo okwu (aka nkwado ala na workpieces nke dị iche iche nha), a na-edozi efere nrụgide dị elu site na ịpị ma ọ bụ onye na-ere ahịa na-emepụta ihe na-emepụta ihe na-akpaghị aka.

Nhazi ahụ Valve: ọnọdụ nke ikpo okwu dị ala (aka nkwado ala na workpieces nke nha dị iche iche), a na-agbanye aka n'akụkụ akụkụ nke kọlụm inyeaka nke ikpo okwu dị ala na mkpara ejector nke nwere ụdị L nwere ma dozie ma ọ bụ onye na-ere ere na-emepụta ihe na-akpaghị aka. ngwaọrụ mmachi.

Nkọwapụta

| Nlereanya | BOSM-DS3030 | BOSM-DS4040 | BOSM-DS5050 | BOSM-DS6060 | |

| Ogo ọrụ | ogologo*obosara | 3000*3000 | 4000*4000 | 5000*5000 | 6000*6000 |

| Isi Driling kwụ ọtọ | Spindle taper | BT50 | |||

| Dayameta igwu mmiri (mm) | φ96 | ||||

| Dayameta ịpị (mm) | M36 | ||||

| Ọsọ Spindle (r/min) | 30-3000/60-6000 | ||||

| Ike moto Spindle (kw) | 22/30/37 | ||||

| Spindle imi gaa n'ebe dị anya | Dị ka ntọala si dị | ||||

| Tinyegharịa nkenke nke ọma (X/Y/Z) | X/Y/Z | ± 0.01 / 1000mm | |||

| Sistemụ njikwa | KND/GSK/SIEMENS | ||||

| Ngwá Ọrụ Magazin | Ngwa akwụkwọ akụkọ Okada nwere ngwaọrụ 24 dị ka nhọrọ | ||||

Nyocha ogo

Igwe ọ bụla nke Bosman na-eji interferometer laser sitere na ụlọ ọrụ United Kingdom RENISHAW, nke na-enyocha nke ọma ma na-akwụghachi ụgwọ maka njehie pitch, azụ azụ, nguzozi nke ọma, na nkwụsi ike ugboro ugboro iji hụ na igwe siri ike, kwụsie ike na nhazi nhazi ya. . Nnwale bọọlụ igwe ọ bụla na-eji ihe nlebanya bọọlụ sitere na ụlọ ọrụ British RENISHAW iji mezie eziokwu okirikiri yana izi ezi geometric, ma mee nnwale ịcha okirikiri n'otu oge iji hụ na igwe 3D nke igwe kwụ ọtọ na izi ezi okirikiri.

Ngwa igwe eji gburugburu ebe obibi

1.1 Ngwa gburugburu chọrọ

Ịnọgide na-enwe ọkwa okpomọkụ mgbe niile bụ ihe dị mkpa maka nhazi nkenke.

(1) Ọnọdụ okpomọkụ dị -10 ℃ ~ 35 ℃. Mgbe okpomọkụ dị n'etiti 20 ℃, iru mmiri kwesịrị ịbụ 40 ~ 75%.

(2) Iji dobe izi ezi nke ngwaọrụ igwe n'ime oke a kapịrị ọnụ, achọrọ ọnọdụ ihu igwe kacha mma ka ọ bụrụ 15 Celsius C ruo 25 Celsius C yana ọdịiche dị na okpomọkụ.

O kwesịghị gafere ± 2 ℃ / 24h.

1.2 Ike ọkọnọ voltaji: 3-phase, 380V, voltaji mgbanwe n'ime ± 10%, ike ọkọnọ ugboro: 50HZ.

1.3 Ọ bụrụ na voltaji dị na ebe a na-eji ya eme ihe na-ejighị n'aka, ngwá ọrụ igwe kwesịrị ịdị na-edozi ọkụ na-achịkwa iji hụ na arụ ọrụ nkịtị nke igwe igwe.

1.4. Ngwá ọrụ igwe kwesịrị inwe ntọ ala a pụrụ ịdabere na ya: waya na-agbanye ala bụ waya ọla kọpa, dayameta waya ekwesịghị ịbụ ihe na-erughị 10mm², na nkwụsị ala na-erughị 4 ohms.

1.5 Iji hụ na arụ ọrụ nkịtị nke akụrụngwa na-arụ ọrụ, ma ọ bụrụ na ikuku abịakọrọ nke ikuku ikuku adịghị emezu ihe achọrọ nke isi iyi ikuku, a ga-agbakwunye otu ngwaọrụ nchacha ikuku (dehumidification, degenreasing, nzacha). igwe ikuku oriri.

1.6. Ekwesịrị idobe ngwa ahụ pụọ na ìhè anyanwụ kpọmkwem, ịma jijiji na ebe okpomọkụ, na pụọ na ndị na-emepụta oge dị elu, igwe ịgbado ọkụ eletrik, wdg, iji zere ọdịda mmepụta igwe ma ọ bụ nkwụsị nke igwe ziri ezi.

Tupu & Mgbe Ọrụ gasịrị

1) Tupu ije ozi

Site n'ịmụ arịrịọ na ozi dị mkpa sitere n'aka ndị ahịa wee zaghachi ndị injinia anyị, ndị otu Bossman Technical na-ahụ maka nkwurịta okwu teknụzụ na ndị ahịa na imepụta ihe ngwọta, na-enyere ndị ahịa aka ịhọrọ ngwọta machining kwesịrị ekwesị na igwe dabara adaba.

2) Mgbe ọrụ gasịrị

A. Igwe ahụ nwere akwụkwọ ikike otu afọ ma kwụọ ụgwọ maka nlekọta ogologo ndụ.

B.During otu afọ akwụkwọ ikike mgbe igwe rutere n'ọdụ ụgbọ mmiri na-aga, BOSSMAN ga-enye ọrụ nrụzi n'efu na oge maka mmejọ dị iche iche na-abụghị nke mmadụ mere na igwe, ma dochie oge ọ bụla ụdị mmebi ahụ na-abụghị nke mmadụ mere n'efu. nke ụgwọ . A ga-edozikwa ọdịda na-apụta oge ikike na ụgwọ kwesịrị ekwesị.

C.Technical support in 24 hours online, TM, Skype, E-mail, na-edozi ajụjụ ndị ikwu na oge. Ọ bụrụ na enweghị ike idozi, BOSSMAN ga-ahazi ozugbo maka injinia azụmaahịa ka ọ bịarute na saịtị maka ndozi, onye na-azụ ahịa chọrọ ịkwụ ụgwọ maka VISA, tiketi ụgbọ elu na ebe obibi.

Saịtị ndị ahịa