Igwe eji egwe ọka CNC dị arọ

Igwe eji egwu egwu CNC

Igwe na-egwupụta ihe na igwe igwe CNC dị elu

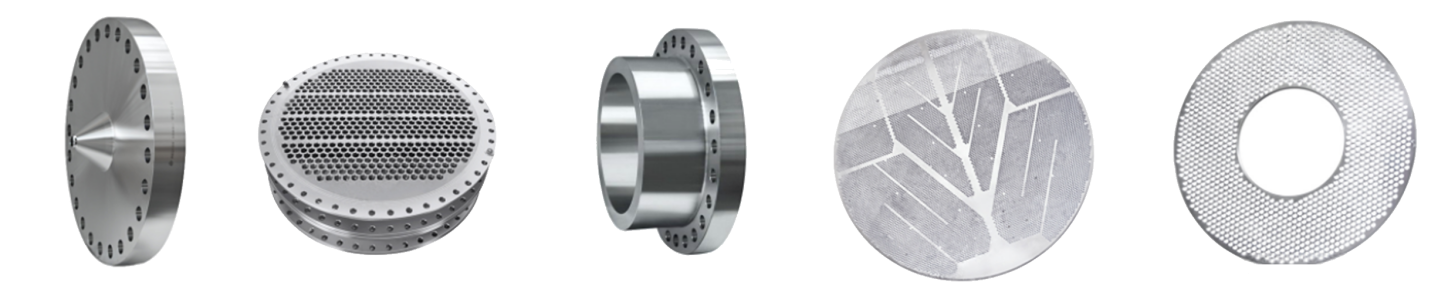

Ngwa igwe

A na-eji igwe igwe CNC na-egwupụta ihe na igwe igwe na-arụ ọrụ nke ọma na-arụ ọrụ nke ọma na ọkpụrụkpụ n'ime oke dị mma dị ka efere, flanges, diski na mgbanaka. Enwere ike ịkụnye oghere site na oghere na oghere n'ụdị ihe dị iche iche. A na-ejikwa igwe dijitalụ na-arụ ọrụ dị mfe. Ọ nwere ike nweta akpaaka, oke nkenke, ọtụtụ ụdị, mmepụta oke.

Iji gboo mkpa nhazi nke ndị ọrụ dị iche iche, ụlọ ọrụ anyị emepụtala igwe dị iche iche. Na mgbakwunye na ụdị ndị a na-ahụkarị, enwere ike ịhazi ya dịka mkpa ndị ahịa si dị.

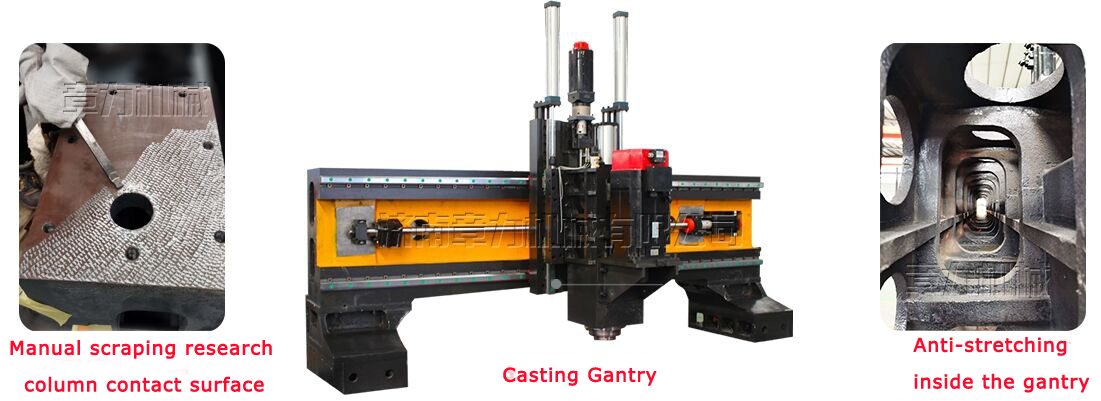

Ọdịdị igwe

Ngwa a bụ nke mejupụtara tebụl bed, gantry na-akpụ akpụ, oche na-akpụ akpụ na-akpụ akpụ, igwu mmiri na igwe igwe igwe, ngwaọrụ mmanye akpaaka na ngwaọrụ nchebe, ngwaọrụ jụrụ oyi, sistemụ njikwa CNC, sistemụ eletriki na ihe ndị ọzọ. Nkwado na ntụzịaka nke ntụzịaka ahịrị na-atụgharị na draịva skru nke ziri ezi, igwe ahụ nwere ezi nguzozi dị elu yana izi ezi n'ọkwa ugboro ugboro.

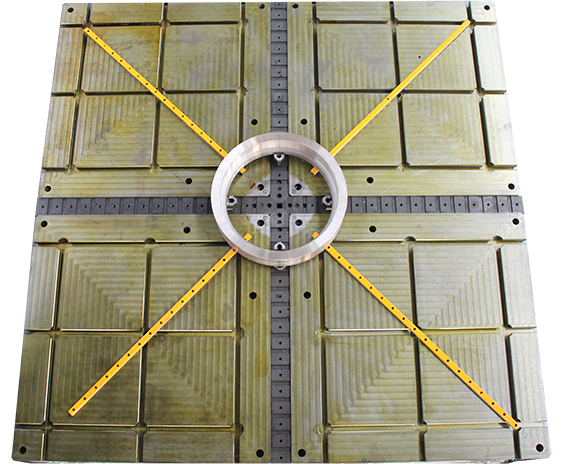

1)Tebụl arụ ọrụ:

Tebụl na-arụ ọrụ na-ewere usoro nkedo, yana ụgbọ elu ahụ nwere oghere T nke nwere nhazi ngwụcha nke ezi uche dị na ya maka ịmachi workpieces. N'elu akwa, a na-ahazi oghere T. Sistemụ draịva ahụ na-eji moto AC servo na nkenke bọọlụ ziri ezi iji kwọọ n'akụkụ abụọ iji mee ka gantry na-aga na ntụzịaka Y-axis. A na-ekesa bolts na-agbanwe agbanwe na ala nke ihe ndina, nke nwere ike ime ka ọ dị mfe ịhazi ọkwa nke tebụl bed.

2)Movinggantry:

A na-eji ígwè isi awọ 250 wụba gantry mkpanaka, ma tinye ụzọ ụzọ abụọ na-agbagharị agbagharị nke nwere ikike dị elu n'akụkụ ihu nke gantry ahụ. Otu ụzọ mkpirisi bọọlụ ziri ezi na moto servo na-eme ka mmịfe isi ike na-aga na ntụzịaka axis X. A na-etinye isi ike mkpọpu na slide isi ike. A na-enweta mmegharị nke gantry site na moto servo na-anya waya bọọlụ na ịghasa bọọlụ site na njikọta nkenke.

3)Movingsadulu na-amị amị:

Sadulu mkpanaka na-amị amị bụ ihe nkedo nkedo nkenke nke ọma. Ihe mmịfe ụgbọ okporo ígwè NC abụọ nwere ike dị elu yana otu ụzọ bọọlụ ziri ezi na ihe mbelata mbara ala dị elu jikọtara ya na moto servo iji kwọọ isi ike mgbapu. Ịga na ntụzịaka Z-axis nwere ike ime ngwa ngwa gaa n'ihu, rụọ ọrụ na-aga n'ihu, ịlaghachi ngwa ngwa, na nkwụsị nke isi ike. Site na mgbawa mgbawa akpaka, iwepụ mgbawa, kwụsịtụ ọrụ.

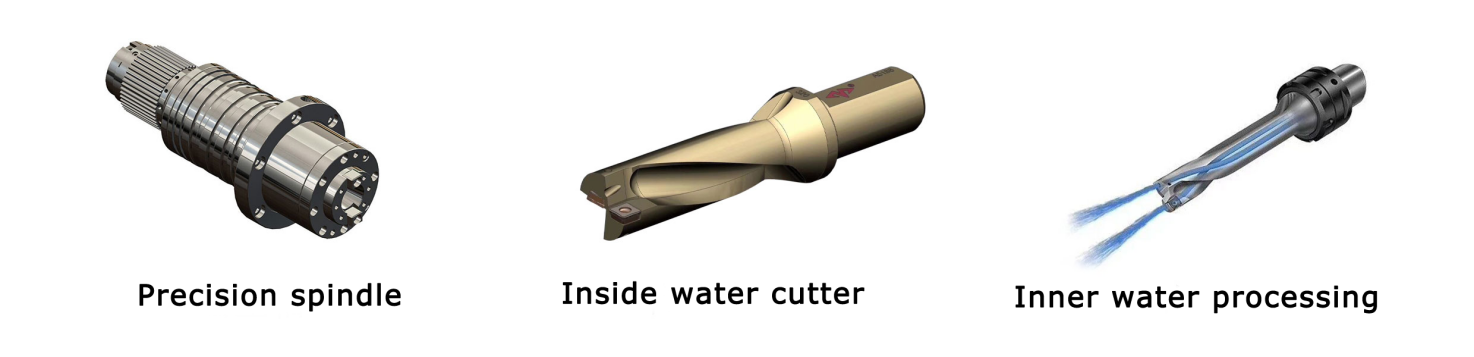

4)Isi ike igwu mmiri(Spindle):

Isi ike mkpọpu na-eji moto servo spindle raara onwe ya nye, nke na-ebunye mkpịsị mkpịsị ziri ezi raara onwe ya nye site n'imebi eriri synchronous ezé ka ọ na-abawanye torque. Mkpanaka ahụ na-eji ọnụ ụzọ kọntaktị Japan dị n'ihu atọ, abụọ na abụọ na ise iji nweta mgbanwe ọsọ na-enweghị nzọụkwụ. Ndochi ngwa ngwa ma dị mfe, a na-ebugharị nri ahụ site na servo moto na skru bọọlụ. Enwere ike ijikọ axes X na Y, a na-ejikwa njikwa loop mechiri emechi iji nweta ọrụ interpolation linear na okirikiri.

Spindle ọgwụgwụ bụ BT40 tapered oghere, onwem na Rotorfoss elu-ọsọ rotary nkwonkwo si Italy, nke nwere ike iji elu-ọsọ U akuakuzinwo (ime ihe ike akuakuzinwo) na isi akuakuzinwo bit na igbapu water.The spindle center mmiri tinyekwa ọrụ nwere ike melite ọnwụ arụmọrụ, ghọta nhazi oghere miri emi ma chebe ngwá ọrụ iji belata ọnụ ahịa eji eme ihe.

5) Ngwa mmanu mmanu na ngwaọrụ nchebe:

dị ka okporo ụzọ nduzi, skru edu, racks, wdg, na-enweghị nkuku nwụrụ anwụ iji hụ na ndụ ọrụ nke igwe igwe. X-axis na Y-axis nke ngwá ọrụ igwe nwere ihe mkpuchi mkpuchi uzuzu, na-etinyekwa ihe nchebe na-ekpuchi mmiri na gburugburu ebe ọrụ.

6)Sistemụ njikwa CNC:

6.1 Site na arụrụ mgbawa mgbawa, enwere ike ịtọ oge mgbawa mgbawa na okirikiri mgbawa na igwe igwe.

6.2 Site na ọrụ ebuli ngwá ọrụ, a pụrụ ịtọ elu ngwá ọrụ na-ebuli elu na igwe-igwe. Mgbe a na-egwupụta ihe na elu a, a na-ebuli ngwa ngwa ngwa ngwa n'elu nke workpiece, mgbe ahụ, a na-atụba mgbawa ahụ, ma na-ebugharị ngwa ngwa n'elu ebe a na-egwupụta ihe na-akpaghị aka na-arụ ọrụ.

6.3 The centralized ọrụ akara igbe na aka-ẹkenịmde unit na-enweta ọnụọgụgụ akara usoro, na-onwem na USB interface na LCD mmiri mmiri kristal ngosi. Iji kwado mmemme, nchekwa, ngosi na nkwurịta okwu, interface ọrụ nwere ọrụ dị ka mkparịta ụka nke igwe mmadụ, nkwụghachi ụgwọ njehie, na mkpu na-akpaghị aka.

6.4 Igwe na-arụ ọrụ nke ịhụchalụ na ịlele oghere oghere tupu nhazi ya, ọrụ ahụ dịkwa mma.

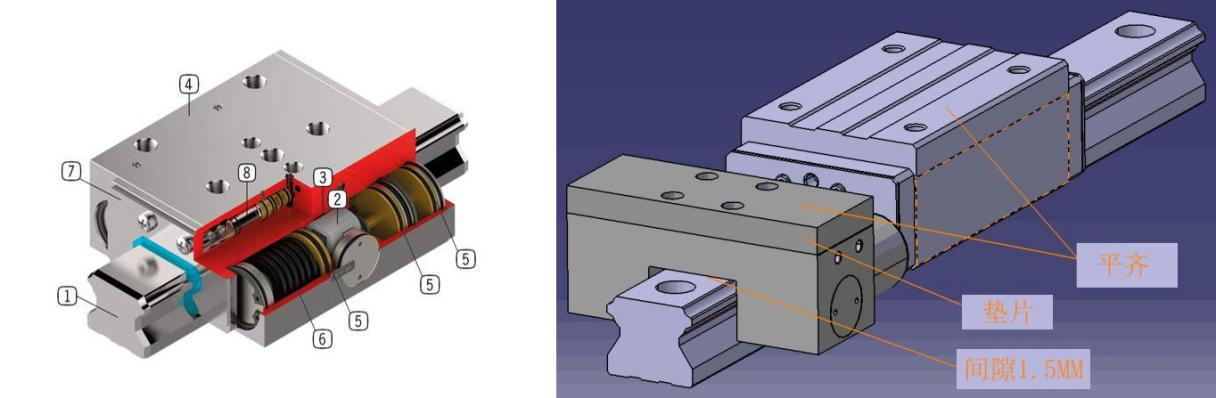

7)Mkpọchi ụgbọ okporo ígwè

Ihe nkedo ahụ nwere ahụ mkpọgide na ihe na-eme ihe. Ọ bụ akụrụngwa na-arụ ọrụ dị elu nke ejiri ụzọ ntuziaka ahịrị na-atụgharị. Ọ na-ebute ike njide siri ike site na ụkpụrụ mgbasawanye nke yiri wedge. Atụmatụ na-abawanye isi ike.

Atụmatụ:

- Nchekwa na ntụkwasị obi, ike njigide siri ike, na-akụda axis XY na-adịghị ebugharị n'oge mkpọpu na ịme ọpịpị.

- Ike njigide dị oke elu, na-abawanye nkwụsi ike nke nri axial, ma gbochie mmegharị ahụ nke obere mkpọtụ kpatara.

- Nzaghachi ngwa ngwa, mmeghe na mmechi oge nzaghachi bụ naanị 0.06 sekọnd, nke na-echebe ngwá ọrụ igwe ma mee ka ndụ nke ịghasa dịkwuo mma.

- Na-adịgide adịgide, elu nickel-plated, ezigbo ọrụ mgbochi nchara.

Nhazi ọhụrụ iji zere mmetụta siri ike mgbe ị na-amachi.

8)Ngwa mgbawa na-ekpo ọkụ na-ekesa akpaaka:

A na-ahazi ihe mgbawa na-akpaghị aka na azụ nke ebe a na-arụ ọrụ ma na-ahazi nzacha na njedebe. Ihe mgbapụta mgbawa akpaka bụ ụdị yinye dị larịị, a na-etinyekwa mgbapụta jụrụ oyi n'otu akụkụ. A na-ejikọta mpụta nke mgbawa na usoro nzacha mmiri nke etiti. The coolant na-asọba n'ime mgbawa ejector. Mgbawa ejector na-ebuli mgbapụta na-ebuba ihe jụrụ oyi n'ime usoro nzacha mmiri nke etiti. Igwe mgbapụta dị elu na-eme ka mmiri dị jụụ na-ekesa ihe nzacha akọrọ maka ịkpụ na jụrụ oyi. A kwadebere ya na mgbawa na-ebufe trolley, nke dị nnọọ mma ibufe ibe ígwè. Akụrụngwa a nwere usoro nju oyi n'ime na nke mpụga maka ndị na-egbu anụ. Mgbe a na-egwupụta ihe na oke ọsọ, a na-eme ka ndị na-egbu osisi dị mma site na mmiri dị n'ime na n'èzí n'oge igwe ọkụ.

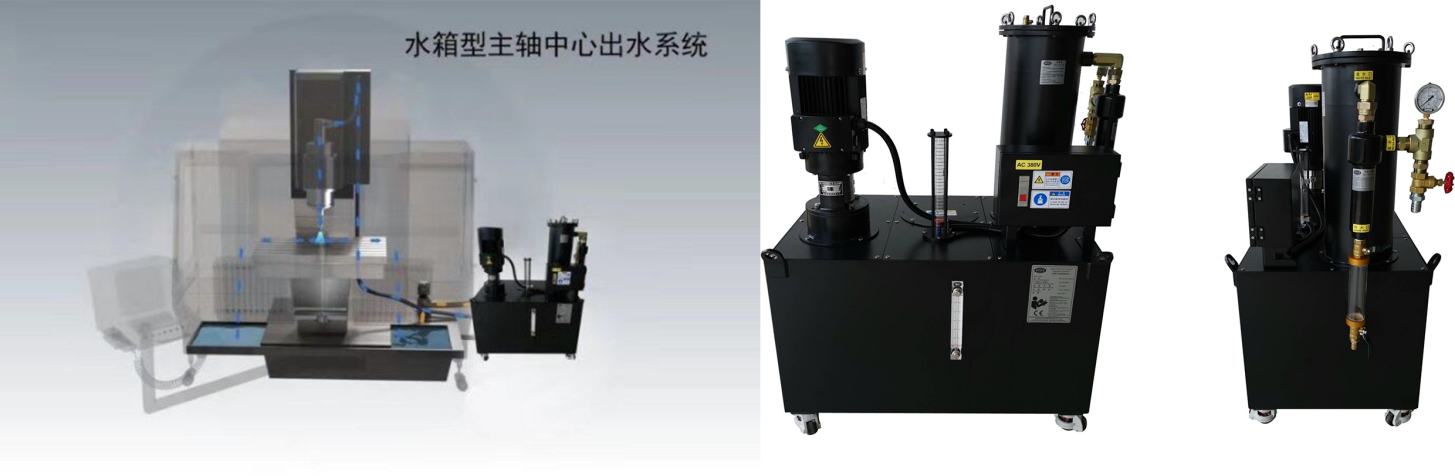

Oti mkpu mmiri dị ala

1) Mgbe coolant na nzacha dị n'etiti mmiri mmiri larịị, usoro na-akpaghị aka na-ejikọta moto na-amalite, na coolant na mgbawa remover na-akpaghị aka eruba n'ime iyo. Mgbe ọkwa mmiri dị elu ruru, moto na-akwụsị ịrụ ọrụ ozugbo.

2) Mgbe coolant dị na nzacha dị na ọkwa dị ala, sistemụ ahụ ga-eme ka nlele ọkwa mmiri na-akpaghị aka na-ama jijiji, spindle ga-ewepụ ngwa ahụ ozugbo, igwe ahụ ga-akwụsịtụ ọrụ.

9)Sistemụ nzacha ọpụpụ etiti:

Ejiri igwe na-eji usoro ntinye mmiri nke etiti dị ka ọkọlọtọ, nke nwere ike nyochaa nke ọma na adịghị ọcha na coolant. The esịtidem ịgba mmiri usoro nwere ike igbochi ígwè atụdo si tangling na ngwá ọrụ n'oge nhazi, mbenata ngwá ọrụ eyi, ịgbatị ngwá ọrụ ndụ, mma workpiece elu imecha, The elu-nrụgide mmiri tinyekwa pin nke agụba n'ọnụ nwere ike nke ọma chebe elu nke workpiece, chebe nkwonkwo rotary dị elu, gbochie ihe ndị na-adịghị ọcha na-egbochi nkwonkwo rotary, ma melite ogo nke workpiece na ịrụ ọrụ nke ọma.

10)Bọọlụ ịghasa na moto agbakwunyere oche:

The moto base bụ a elu concentricity ngwaahịa na-ejikọta bọl na moto. Ejikọnyere ihe ejikọtara ọnụ na kọntaktị angular (ọkwa ziri ezi C5) iji kwalite izi ezi yana hụ na mkpochapụ axial efu nke skru bọọlụ mgbe moto na-aga n'ihu ma tụgharịa. Ọ dị mma karịsịa maka ngwa ngwa ngwa ngwa.

Mgbakọ ziri ezi: a na-etinye bọọlụ bọọlụ na moto n'ime otu site na isi moto. Belata njehie concentricity nke ogwe moto na bọọlụ skru shaft, jikwaa ya na gbakwunyere ma ọ bụ mwepu 0.01mm, na perpendicularity nke njedebe ihu bụ 0.01.

11)Tebụl na-eche onwe ya aka anọ(nhọrọ)

The worktable nke onwe-center akụrụngwa na-onwe na anọ-jaw hydraulic onwe-centering chuck. The workpiece nwere ike centralized na-akpaghị aka na otu mwekota na-enweghị onye ọ bụla workpiece patrolling chọta center. Mkpọchi ahụ dị ngwa ma dịkwa mma.

Dozie nsogbu ahụ na mpempe ọrụ nwere okirikiri indexing na-erughị 1600 mm dayameta na-akụchi site na ịpị efere mgbe nri gasịrị wee chọọ ebe ahụ, nke na-ewe obere oge ma na-ewe ogologo oge clamping karịa oge nhazi.

Iche onwe ya anọ na-agba agba n'onwe ya nke nwere nnukwu agba strok na-eme ka ọ sie ike maka workpiece imetụ agba ahụ aka mgbe ị na-akụ ya. A na-eji ihe owuwu nke warara na pad. Ọ na-edozi ọnọdụ na hydraulic ma ọ bụ pneumatic jaws nwere obere njem na ahịa na nnukwu workpieces ga-emetụta agba agba mgbe ọ na-ebuli elu, na-emebi chucks.

The anọ jaws na workbench bụ disassemblable style, na mwepụ nke n'azụ workbench bụ a nkịtị ikpo okwu na ya T-groove.It enhances ngwa nso nke ndị ọzọ workpieces ma e wezụga mgbanaka.

Nkọwapụtan

| Nlereanya | BOSM-DT1010 | BOSM-DT2010 | BOSM-DT2016 | BOSM-DT2525 | |

| Ogo ọrụ | Ogologo* Obosara (mm) | 1000x1000 | 2000x1000 | 2000x1600 | 2500x2500 |

| Isi Driling kwụ ọtọ | Spindle taper | BT40/BT50 | BT40/BT50 | BT40/BT50 | BT40/BT50 |

| Dayameta mkpọpu mmiri (mm) | Φ40/Φ60 | Φ40/Φ60 | Φ40/Φ60 | Φ40/Φ60 | |

| Dayameta ịpị (mm) | M24/M36 | M24/M36 | M24/M36 | M24/M36 | |

| Ọsọ spindle (r/min) | 30-3000 | 30-3000 | 30-3000 | 30-3000 | |

| Ike spindle (Kw) | 15/22 | 15/22 | 15/22 | 15/22 | |

| Ebe dị anya site na njedebe nke spindle ruo n'elu ọrụ (mm) | 200-600 / 400-800 | 200-600 / 400-800 | 200-600 / 400-800 | 200-600 / 400-800 | |

| Tinyegharịa nkenke nke ọma (X/Y/Z) | X/Y/Z | ± 0.01 / 1000mm | ± 0.01 / 1000mm | ± 0.01 / 1000mm | ± 0.01 / 1000mm |

| Nnukwu ibu (T) | 8.5 | 11 | 13.5 | 16.5 | |

| Ngwá ọrụ magazin | Ahịrị ngwá ọrụ magazin | ||||

Nyocha ogo

Igwe ọ bụla nke Bosman na-eji interferometer laser sitere na ụlọ ọrụ United Kingdom RENISHAW, nke na-enyocha nke ọma ma na-akwụghachi ụgwọ maka njehie pitch, azụ azụ, nguzozi nke ọma, na nkwụsi ike ugboro ugboro iji hụ na igwe siri ike, kwụsie ike na nhazi nhazi ya. . Nnwale bọọlụ igwe ọ bụla na-eji ihe nlebanya bọọlụ sitere na ụlọ ọrụ British RENISHAW iji mezie eziokwu okirikiri yana izi ezi geometric, ma mee nnwale ịcha okirikiri n'otu oge iji hụ na igwe 3D nke igwe kwụ ọtọ na izi ezi okirikiri.

Tupu & Mgbe Ọrụ gasịrị

1) Tupu ije ozi

Site n'ịmụ arịrịọ na ozi dị mkpa sitere n'aka ndị ahịa wee zaghachi ndị injinia anyị, ndị otu Bossman Technical na-ahụ maka nkwurịta okwu teknụzụ na ndị ahịa na imepụta ihe ngwọta, na-enyere ndị ahịa aka ịhọrọ ngwọta machining kwesịrị ekwesị na igwe dabara adaba.

2) Mgbe ọrụ gasịrị

A. Igwe ahụ nwere akwụkwọ ikike otu afọ ma kwụọ ụgwọ maka nlekọta ogologo ndụ.

B.During otu afọ akwụkwọ ikike mgbe igwe rutere n'ọdụ ụgbọ mmiri na-aga, BOSSMAN ga-enye ọrụ nrụzi n'efu na oge maka mmejọ dị iche iche na-abụghị nke mmadụ mere na igwe, ma dochie oge ọ bụla ụdị mmebi ahụ na-abụghị nke mmadụ mere n'efu. nke ụgwọ . A ga-edozikwa ọdịda na-apụta oge ikike na ụgwọ kwesịrị ekwesị.

C.Technical support in 24 hours online, TM, Skype, E-mail, na-edozi ajụjụ ndị ikwu na oge. Ọ bụrụ na enweghị ike idozi, BOSSMAN ga-ahazi ozugbo maka injinia azụmaahịa ka ọ bịarute na saịtị maka ndozi, onye na-azụ ahịa chọrọ ịkwụ ụgwọ maka VISA, tiketi ụgbọ elu na ebe obibi.

Saịtị ụlọ ọrụ