Gịnị bụ CNC mkpọpu ala na igwe igwe:

Igwe na-egwupụta ihe CNCbụ nke igwe eji egbutu igwe, yana ọrụ nke nhazi oghere, ịkụ ala, ịkụ aka, na-agwụ ike na igwe nri inyeaka. A na-ejikarị ya maka mkpọpu ihe dị elu nke efere dị larịị, flanges, diski, mgbanaka na ihe ndị ọzọ na-arụ ọrụ nke ọkpụrụkpụ ha dị n'ime oke dị irè.

Enwere ike ịme ihe site na oghere na oghere kpuru n'otu akụkụ ihe onwunwe na ihe ndị mejupụtara. A na-achịkwa usoro nhazi nke igwe eji eme ihe, na ọrụ ahụ dị nnọọ mma. Ọ nwere ike na-aghọta akpaaka, elu nkenke, multiple iche, na uka mmepụta.

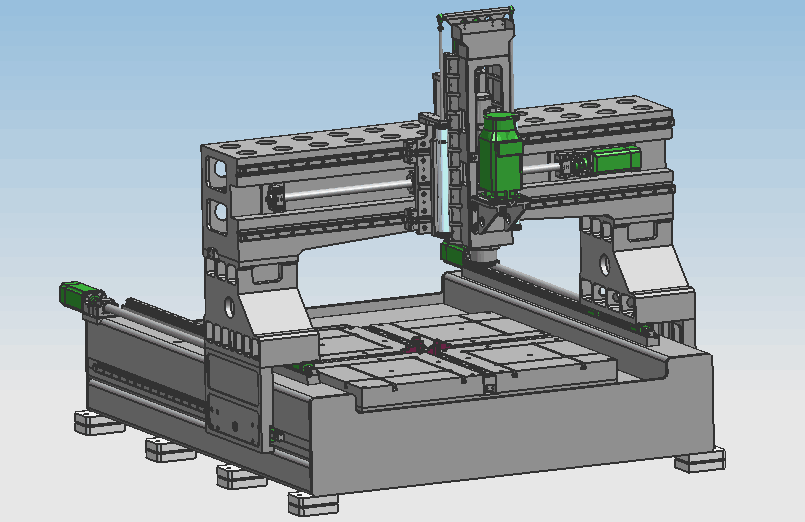

Igwe igwe na-egwuputa ihe na igwe igwe CNCakụrụngwa nhazi

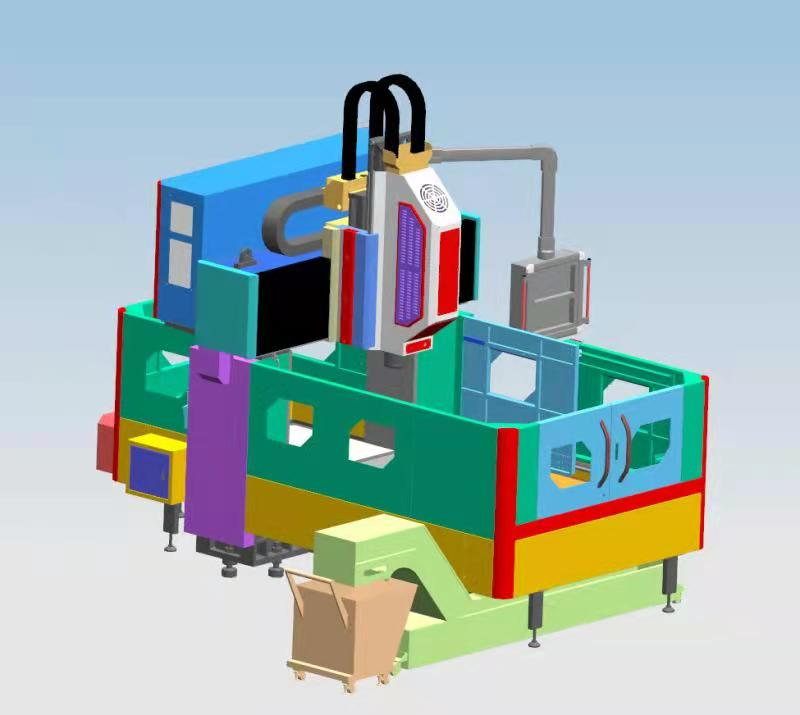

1. akwa:

Ihe ndina ahụ bụ akụkụ dị mkpa, nke emechara site na ọgwụgwọ mgbakasị nke abụọ, na-enwe ezigbo ike ike na static siri ike na enweghị nrụrụ. Tebụl na-arụ ọrụ na-anabata usoro nkedo, ma enwere T-slot nwere nhazi ngwụcha nke ezi uche dị na ụgbọ elu, nke a na-eji kụgide ihe arụ ọrụ. Sistemụ draịva ahụ na-anabata moto AC servo na bọọlụ ziri ezi ịnya ụgbọ ala n'akụkụ abụọ iji mee ka gantry na-aga na ntụzịaka X-axis. A na-ekesa bolts na-agbanwe agbanwe na ala ala nke ihe ndina, nke nwere ike ịhazigharị ọkwa nke ihe ndina ahụ n'ụzọ dị mfe.

2. Mobile ụdị gantry:

A na-eji ígwè isi awọ (HT250) na-edozi ma na-edozi gantry a na-ebugharị ebugharị, ma tinyekwa ụzọ ntuziaka ahịrị kwụ ọtọ nwere ikike dị elu n'akụkụ ihu nke gantry. Otu ụzọ mkpirisi bọọlụ ziri ezi na moto servo na-eme ka ihe mmịfe powerhead na-aga na ntụzịaka Y-axis, a na-etinyekwa isi ihe mgbapu na slide powerhead. A na-enweta mmegharị nke gantry site na ntụgharị nke mkpọgharị bọọlụ nke moto servo na-ebugharị site na njikọ ziri ezi.

3. Saddle na-akpụ akpụ:

Saddle na-amị amị bụ nhazi nke nkedo nke ọma. A na-eji ihe mkpuchi ụgbọ okporo ígwè CNC abụọ dị elu na-ebu ibu dị elu, otu ụzọ nkedo bọọlụ ziri ezi na ihe mgbanaka mbara ala dị elu jikọtara ya na moto servo iji kwọọ isi ike na-agbagharị na-aga n'ụzọ Z-axis. nwere ike ịghọta isi ike ngwa ngwa, na-arụ ọrụ na-aga n'ihu, ngwa ngwa ngwa ngwa, kwụsị na omume ndị ọzọ. Ọ nwere ọrụ nke mgbawa mgbawa akpaka, iwepụ mgbawa na kwụsịtụ.

4. Ịkụba isi ike

Isi ike mkpọpu na-eji moto servo spindle raara onwe ya nye, bụ nke a na-ebugharị eriri mgbanaka nha nha nha na-eme ka ọ na-abawanye torque iji kwọọ mkpara ziri ezi raara onwe ya nye. The spindle adopts n'ihu anọ na azụ abụọ ahịrị isii nke Japanese angular kọntaktị bearings iji nweta stepless ọsọ mgbanwe. A na-eji spindle nwere usoro mgbanwe ngwá ọrụ pneumatic iji mee ka ngwá ọrụ ahụ dị ngwa ngwa ma dị mfe, na nri na-ebugharị site na servo moto na bọmbụ bọl. Enwere ike ijikọ axes X, Y na Z wee were akara akaghị nke mechiri emechi ka ọ mata ọrụ interpolation linear na okirikiri.

Kwuo egwuIgwe uru

1.Mmiri si n'ogwe osisi:

Ọ na-anakwere mkpịsị mmiri mmiri mmiri nke Taiwan Jianchun na servo spindle moto dị elu iji kwọọ eriri ahụ site na mgbada belt synchronous ga-eme ka ọ dịkwuo ike. Nwere ike iji akwa mgbawa U-ọsọ (na-eme ihe ike) na nhazi mmiri nke etiti etiti.

2. Mgbochi

Anyụike X na Y nwere ihe arụrụ arụ ọrụ dị elu ejiri na njikọ mkpọchi na ụzọ ntụzịaka ahịrị na-atụgharị. N'iji ụkpụrụ nke wedge blocks, ọ nwere ọrụ nke idozi gantry, nhazi nke ọma, igbochi ịma jijiji na imeziwanye ike. Ọdịdị ahụ bụ kọmpat ma dị ike.

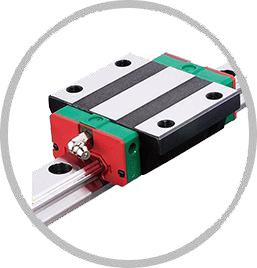

3. Linear ndu na bọọlụ ịghasa

Ọ nakweere ụgbọ okporo ígwè akara akara Taiwan Shangyin na ịghasa bọọlụ akara TBI. A na-etinye okporo ụzọ ntuziaka n'akụkụ abụọ nke akwa igwe kwụ ọtọ na n'ahịrị, na ike dị ọbụna, na-eme ka igwe kwụsie ike na ịgba ọsọ nke igwe.

4. Ike isi itule cylinder

Enwere cylinders nguzozi abụọ n'elu isi ike iji dozie ịdị arọ nke isi igwe. N'oge nhazi ahụ, isi igwe na-akwụsi ike, ịdị nro nke oghere ahụ na-eme ka ọ dịkwuo mma, na-eyi na nkedo Z-axis na-ebelata.

5. Usoro mwepụ nke mgbawa

Enwere ebufe mgbawa mgbawa yinye n'azụ akụrụngwa igwe. Jiri egbe mmiri dị elu mee ihe ngwa ngwa na-agbanye ígwè n'ime ngwa ngwa mgbawa, nke na-ebufe akwụkwọ ígwè ahụ, na-echekwa oge maka nhicha akwụkwọ nke ígwè na ibelata ọrụ. A na-ebufe mgbawa nwere oriọna ọkwa ọkwa mmiri, nke na-eme ka ọ na-ada ụda na-akpaghị aka mgbe mmiri ịkpụ ahụ ezughi oke.

Nkwanye nlereanya

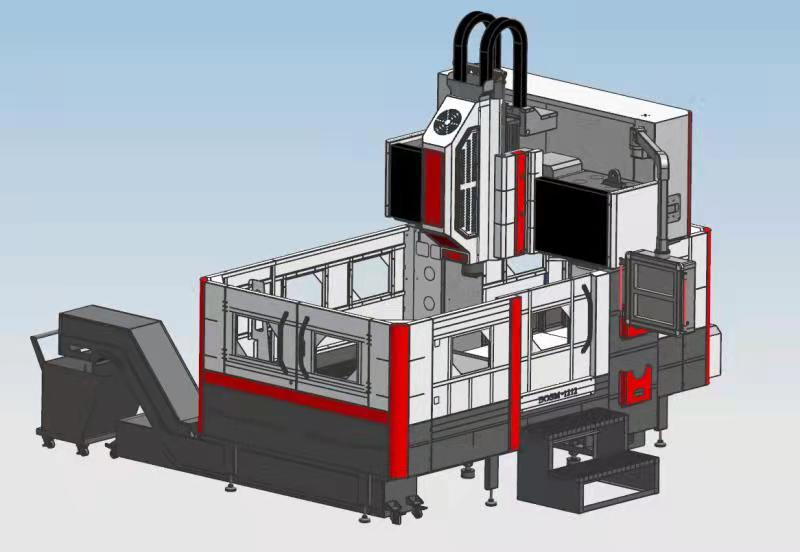

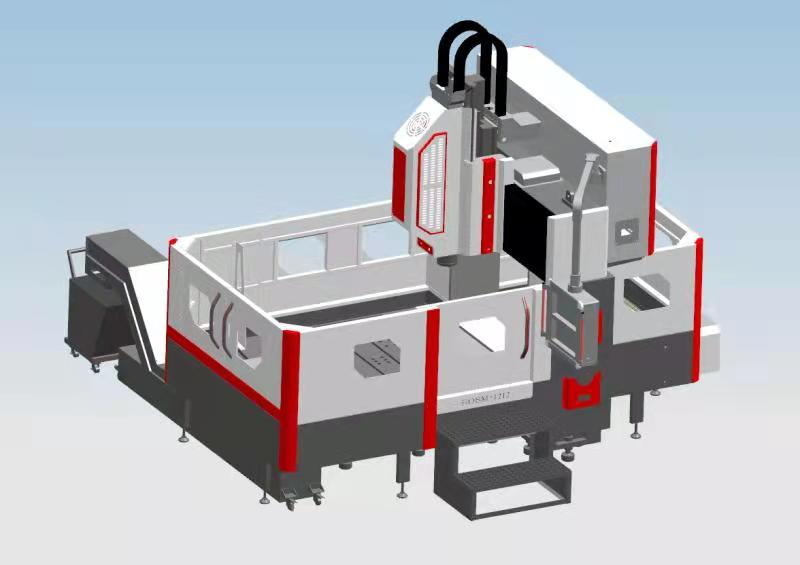

BOSM1600*1600 CNC na-egwupụta ihe na igwe igwe igwe

BOSM1600*1600 ụdị elu-ọsọgantry CNC mkpọ ala na-egwe ọkaigwenwere ọrịa strok nhazi dị irè nke 1600 * 1600, nke bụ ngwá ọrụ bara uru. The igwe nwere a anọ-jaw onwe-center worktable, nke na-eme ka ọ dịkwuo mfe na ngwa ngwa ka mwekota mgbanaka workpieces. Ogwu kacha elu bụ 50, Ọ nwere ike iji mgbapu mmiri dị n'ime ime mmiri dị elu, ụgbọ elu igwe igwe, igwe igwe, na nhazi ndị ọzọ. The akụrụngwa nwere ike kwadebere na ngwá ọrụ magazin na-aghọta multiple usoro na otu clamping.

BOSM2500 * 2500 CNC na-egwupụta ihe na igwe igwe

BOSM-2525 Ụdị gantry zuru ezu ụdị nkewaCNC dị eluigwe na-egwuputa ihe usoro na-tumadi-eji maka elu-arụmọrụ mkpọ ala nke nnukwu efere, ifufe ike structural akụkụ, discs, engineering ígwè structural akụkụ, valves, tube Ibé akwụkwọ na ndị ọzọ workpieces n'ime irè nso. Ịgba igwe. Enwere ike ịme ihe site na oghere na oghere kpuru n'otu akụkụ ihe onwunwe na ihe ndị mejupụtara. A na-achịkwa usoro nhazi nke igwe eji eme ihe, na ọrụ ahụ dị nnọọ mma. Na mgbakwunye na ụdị ndị a na-ahụkarị, enwere ike ịhazi na hazie ha dịka mkpa ndị ọrụ siri dị.

CNC akpaka mkpọpu igweA na-eji ya eme ihe ugbu a na ụlọ ọrụ valvụ, ụlọ ọrụ flange, ụlọ ọrụ ọkụ eletrik na-agbawa agbawa, ụlọ ọrụ ike ikuku, ụlọ ọrụ igwe akwa, ụlọ ọrụ na-ewu ụlọ, ụlọ ọrụ igwe, ụlọ ọrụ ụgbọ ala, wdg.

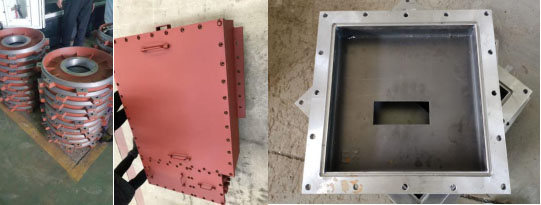

N'ihi na ndị ahịa na-na-na-na-na-na-na-na gburugburu ngwaahịa dị ka flanges, yiri mgbaaka, slewing supports, tube Ibé akwụkwọ, wdg, mpụta dayameta bụ ihe na-erughị 2.2m, index okirikiri bụ n'ime 2m na dayameta, na oghere bụ n'ime 50mm. Ihe mgbu maka ndị ahịa nke ụdị ngwaahịa a na-adabere na oge nkwụsịtụ karịa oge nhazi, ngwa nhazi omenala, dị ka.CNC gantrị igwe igwema ọ bụ radial drill, na-eji ihe nkedo na-agbanye ihe ahụ mgbe ị na-ebunye ya, wee jiri ihu ihu ma ọ bụ jiri ngwá ọrụ ọkachamara nwalee tebụl iji chọta etiti ahụ, nke na-ewe oge na arụmọrụ.

Ihe BOSMakuakuzinwoigweemebere ya na tebụl arụrụ arụ ọrụ na igwe na-akpụ akpụ. Ọ na-anakwere nnukwu njem njem anọ na-eme onwe ya, nke na-edozi nsogbu nke obere hydraulic ma ọ bụ pneumatic jaws na ahịa. Nnukwu workpieces ga-adaba n'agba mgbe hoisting N'ihe banyere mmebi nke chuck, workbench na-nyere a warara Ọdịdị pad, na clamping na-akpaghị aka hiwere isi n'otu oge, nke na-edozi nsogbu nke clamping na-ewe oge.

Agụ anọ dị na workbench na-ewere ụdị a na-apụghị ịpụ apụ. Mgbe disassembly, workbench ka bụ a ot ikpo okwu na T-oghere oghe, nke mma ya ngwa nso maka machining ndị ọzọ workpieces n'èzí nke gburugburu. BOSMigwe igwe CNCA kwadebere ya na njigide okporo ụzọ ụgbọ okporo ígwè, 0.06 sekọnd dị oke elu na oghere mmechi na oge nzaghachi, nke na-eme ka nhazi machining dị mma na ike njigide, na-edozi nsogbu gara aga nke ịma jijiji na ndụ ngwá ọrụ. Z-axis okpukpu abụọ nke cylinder, ịdọrọ mmanụ na gas kewapụrụ na ọkụ eletrik, usoro kwụsiri ike na nke siri ike, ogwe ọkụ eletrik dị n'azụ maka njem dị mfe, ụdị ọganihu usoro dị mfe iji rụọ ọrụ, enwere ike iji arịlịka bolts mgbe ọdịda na larịị.

BOSMigwe egwu egwu akpaka emeziwanyela ma kwalite akụkụ isi nke oghere kọlụm. Mgbe a gbanwere kọlụm ahụ, a na-eme ka mpempe akwụkwọ mmiri na-eme ka ọ dịkwuo mma, mmetụta mmiri na-adịghị mma dị mma, na ọdịdị ọdịdị ahụ nwere ike ịchọ mma.

BOSM cnc igwe na-egwuputa ihea kwadebere ya na usoro ntinye mmiri nke etiti, na nrụgide mmiri dị oke elu. Ọdịdị nke igwe na-egbu azụ azụ nke ihe nlereanya a adịghị mfe ihicha ígwè ígwè n'ihu. Ejiri ya egbe mmiri ịsacha ụgbọ ala iji sachaa mkpụkpụ ígwè azụ.

Ụlọ ọrụ Valve

Ụlọ ọrụ Flange

Ụlọ ọrụ eletrik na-egbochi mgbawa

Ụlọ ọrụ ike ikuku

Ụlọ ọrụ igwe akwa

Ụlọ ọrụ igwe

Ụlọ ọrụ mmepụta ihe

Ụlọ ọrụ ụgbọ ala

Ụlọ ọrụ BOSM ka na-ejikọta ahịa mgbe niile ma na-emepụta ụdị ọhụrụ iji belata mmepụta na mmepụta ihe. Ọ nwere ọrụ nhazi dị ukwuu, jikọtara ya na ahụmahụ mkpọpu mmiri, yana ọrụ igwe nri kachasị mma. Ọmụmaatụ, BOSM-DPH1212 nke edobere beamigwe igwe iheanyị emebela ma chepụta ugbu a. N'ihi na ndị dị mkpa ka akuakuzinwo na igwe nri na a nhazi obosara nke 1200mm ma ọ bụ obere, ihe echekwa gantry.igwe na-egwuputa ihe na igwe igwena-enweghị ike hazie karịrị obosara nke VMC850 machining center na ahịa nwere ike na-aghọta ndị ahịa 'egwe ọka dabeere nhazi. Ụdị na usoro nke usoro.

Ụdị BOSM-DPH1212 nwere ike ịghọta ngwa ngwa na-ebuli elu na njem, obosara nwere ike ibunye n'ime akpa ahụ, enwere ike ịtọ ya ngwa ngwa ma jiri ya mee ihe n'ebe ndị ahịa. Akọwapụtara dị ka mkpọpu ala niile naigwe igwe igweihe nlereanya etiti, ọ dị mkpa iji hụ na izi ezi na nkwụsi ike nke ngwá ọrụ igwe. Ntuziaka atọ axis ga-eji ntuziaka roller ika Taiwan, skru na-egweri, na ebe a na-arụ ọrụ maka ịmecha igwe iji hụ na arụ ọrụ igwe.

BOSM-DPH1212 ofobe beam gantry milling na-agbalịsi ike maka ahịa ebe a na-apụghị idozi obosara nke ụlọ ọrụ machining, na ngwaahịa nhazi na-efunahụ nnukwu igwe igwe. Dịka ọmụmaatụ, 1mCNC gantry machining centerna ahịa, anyị na-ezubere iche a ọnụ ọgụgụ buru ibu nkeCNC egwu egwu, egwe ọka, na-agwụ ike. The ahịa na-achọ maka machining, e nwekwara ahịa na-edozi nsogbu nke siri ike machining nke ebu ụdị ihe osise na-egwe ọka electromechanical spindles.

Oge nzipu: Sep-20-2021